© 2020 Carrier

11

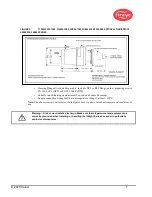

4. Consideration must be given to burner secondary air rotation, some burners have clockwise

(CW) air rotation and others have counterclockwise (CCW) air rotation. If combustion air enters

the furnace with a rotational movement of sufficient velocity to deflect the ignitor flame in the

direction of rotation, position the scanner 10 to 30 degrees downstream of the ignitor as shown

in Figure 4 and close to the periphery of the burner throat (See Figure 3).

FIGURE 4.

SCANNER LOCATION VS. SECONDARY AIR ROTATION

CCW ROTATION

CW ROTATION

5.

Having determined the approximate location for the sight pipe, cut a clearance hole for a 2 inch

pipe through the burner plate. Look through the hole. If register vanes interfere with the desired

line of sight, the interfering vane(s) should be trimmed to assure an unrestricted viewing path at

all firing levels as indicated in Figure 5.

Note: Always check with the burner manufacturer before you trim register vanes.

FIGURE 5.

IF POSSIBLE, FLAME SHOULD COMPLETELY COVER SIGHT OPENING

NOT THIS

NOT THIS

BUT THIS

OR THIS

6. The preferred method for mounting surface mounted scanners requires the use of a swivel

mount, P/N 60-1664-X, shown in Figures 7, 8, and 9. Center the swivel mount over the two inch

hole in the burner plate and secure using three hexed cap screws (not provided). Install the sight

pipe on the swivel mount. If a swivel is not used, insert the end of the sight pipe into the hole,

align the hole to the desired viewing angle and tack weld (welding must be adequate to temporarily

support the weight of the installed scanner). The sight pipe should be arranged to

slant downward so that dirt and dust will not collect inside.

CAUTION: Use no more than one foot of one inch diameter sight pipe. Increase the sight

pipe diameter one inch for every additional foot of sight pipe length used to avoid

restricting the scanner’s field of view.

When a satisfactory sighting has been confirmed by operational testing, secure the swivel

mount’s ball position in place by tightening the three hex head cap screws located on the

swivel mount ring.

7. In larger multi-burner type applications such as power, kiln or refinery burners, it is recognized

that there may be several obstructions within the scanner overall range of view. The same princi-

ple of adjusting the scanner such that the flame is within the center of its field of view applies.

Use of a swivel mount allows the scanner to be adjusted to target the flame within the center of

the scanner range of view. (See obstructed view in figure 6 above).

8.

For ease of use, the scanner should be installed on the sight pipe so the OLED display can

easily be read.

Note: Operation of the display is independent of position.

MAIN

BURNER

MAIN

BURNER

Summary of Contents for InSight 4 Series

Page 19: ... 2020 Carrier 19 Figure 14 WIRING DIAGRAM 95UVS4 1 95IRS4 1 with 59 547 cable ...

Page 27: ... 2020 Carrier 27 THE MAIN STATUS MENU FIGURE 20 MAIN STATUS MENU LOOP ...

Page 36: ... 2020 Carrier 36 THE CONFIG MENU FIGURE 23 CONFIG MENU LOOP ...

Page 40: ... 2020 Carrier 40 THE AUTO CONFIG MENU FIGURE 25 AUTO CONFIG MENU LOOP ...

Page 43: ... 2020 Carrier 43 THE FILE COPY MENU FIGURE 26 FILE COPY MENU LOOP ...

Page 45: ... 2020 Carrier 45 THE 4 20 mA MENU FIGURE 27 4 20mA MENU LOOP ...

Page 47: ... 2020 Carrier 47 THE DATE TIME MENU FIGURE 28 DATE TIME MENU LOOP ...

Page 49: ... 2020 Carrier 49 THE COMMS MENU FIGURE 29 COMMS MENU ...

Page 51: ... 2020 Carrier 51 THE MANUAL CONFIG MENUS FIGURE 30 ...

Page 52: ... 2020 Carrier 52 MANUAL CONFIG MENUS continued FIGURE 31 ...