FIREPOWER 160S

SAFETY INSTRUCTIONS

Safety Instructions

1-2

Manual 0-5369

WARNING

ARC RAYS can burn eyes and skin; NOISE can

damage hearing. Arc rays from the welding

process produce intense heat and strong

ultraviolet rays that can burn eyes and skin.

Noise from some processes can damage

hearing.

1. Wear a welding helmet fitted with a proper shade of

filter (see ANSI Z49.1 listed in Safety Standards) to

protect your face and eyes when welding or watching.

2. Wear approved safety glasses. Side shields

recommended.

3. Use protective screens or barriers to protect others

from flash and glare; warn others not to watch the arc.

4. Wear protective clothing made from durable,

flame-resistant material (wool and leather) and foot

protection.

5. Use approved ear plugs or ear muffs if noise level is

high.

WARNING

FUMES AND GASES can be hazardous to your

health.

Welding produces fumes and gases. Breathing

these fumes and gases can be hazardous to

your health.

1. Keep your head out of the fumes. Do not breathe the

fumes.

2. If inside, ventilate the area and/or use exhaust at the

arc to remove welding fumes and gases.

3. If ventilation is poor, use an approved air-supplied

respirator.

4. Read the Material Safety Data Sheets (MSDSs) and the

manufacturer’s instruction for metals, consumables,

coatings, and cleaners.

AWS F2.2:2001 (R2010), Adapted with permission of the American Welding Society (AWS), Miami, Florida

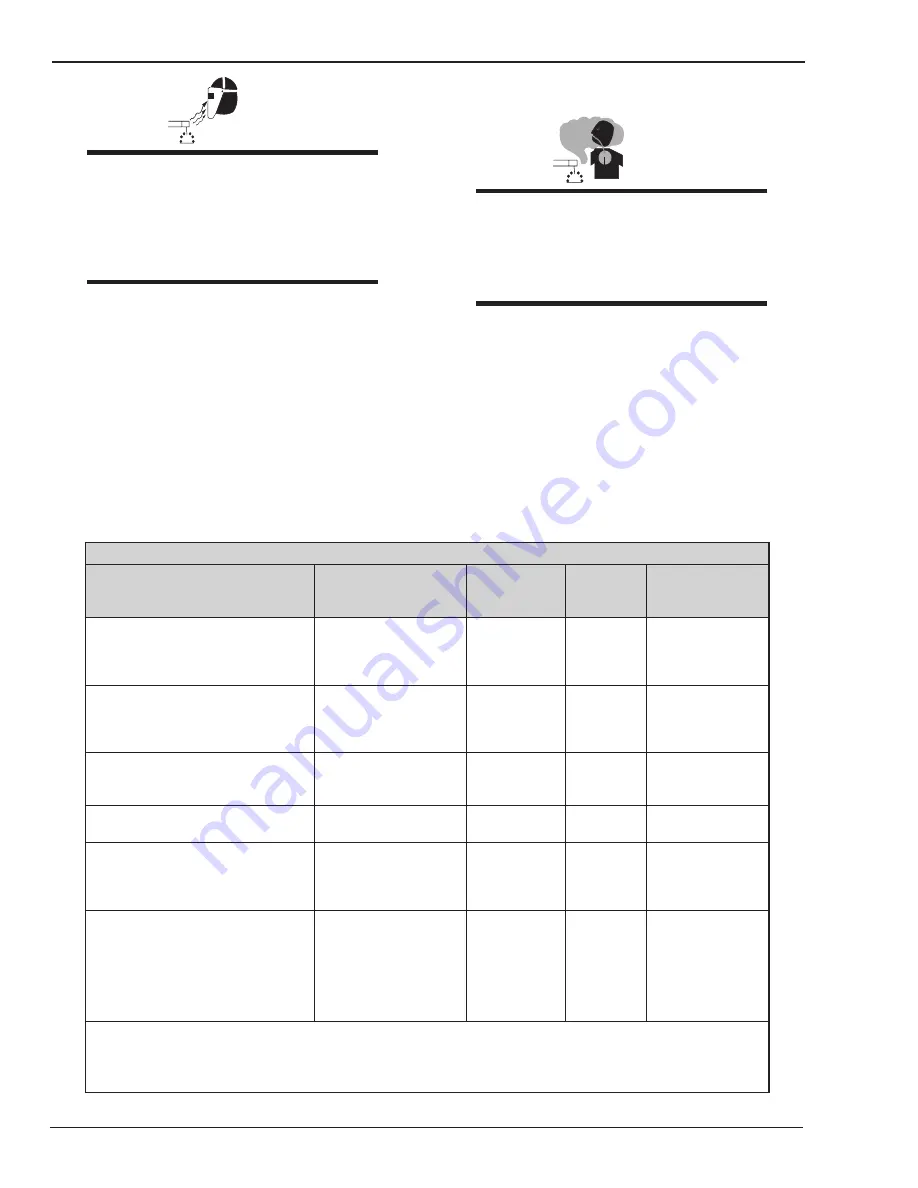

Guide for Shade Numbers

Process

Electrode Size in. (mm)

Arc Current

(Amperes)

Minimum

Protective

Shade

Suggested* Shade

No. (Comfort)

Shielded Metal Arc Welding (SMAW)

Less than 3/32 (2.4)

3/32-5/32 (2.4-4.0)

5/32-1/4 (4.0-6.4)

More than 1/4 (6.4)

Less than 60

60-160

160-250

250-550

7

8

10

11

-

10

12

14

Gas Metal Arc Welding (GMAW) and

Flux Cored Arc Welding (FCAW)

Less than 60

60-160

160-250

250-550

7

10

10

10

-

11

12

14

Gas Tungsten arc Welding (GTAW)

Less than 50

50-150

150-500

8

8

10

10

12

14

Air Carbon Arc Cutting (CAC-A)

(Light)

(Heavy)

Less than 500

500-1000

10

11

12

14

Plasma Arc Welding (PAW)

Less than 20

20-100

100-400

400-800

6

8

10

11

6 to 8

10

12

14

Plasma Arc Cutting (PAC)

Less than 20

20-40

40-60

60-80

80-300

300-400

400-800

4

5

6

8

8

9

10

4

5

6

8

9

12

14

* As a rule of thumb, start with a shade that is too dark to see the weld zone. Then go to a lighter shade which gives sufficient

view of the weld zone without going below the minimum. In oxyfuel gas welding, cutting, or brazing where the torch and/or

the flux produces a high yellow light, it is desirable to use a filter lens that absorbs the yellow or sodium line of the visible

light spectrum.

Table 1-1: Guide for Shade Numbers