REV. 01 2016

27 / 28

CHAPTER 9

– MAINTENANCE

Only trained personnel who knows how the lift works, must be allowed to service

the lift

.

To service properly the lift, the following has to be carried out:

use only genuine spare parts as well as equipment suitable for the work required;

follow the scheduled maintenance and check periods shown in the manual;

discover the reason for possible failures such as too much noise, overheating, oil blow-by, etc.

refer to documents supplied by the manufacture or dealer to carry out maintenance.

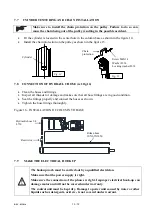

Before carrying out any maintenance or repair on the lift, disconnect the power

supply, padlock the general switch and keep the key in a safe place to prevent

unauthorized persons from switching on or operating the lift

9.1

ORDINARY MAINTENANCE

The lift has to be properly cleaned at least once a month using self-cleaning clothes.

The use of water or inflammable liquid is strictly forbidden

Be sure the rod of the hydraulic cylinders is always clean and not damaged since this may result in

leakage from seals and, as a consequence, in possible malfunctions.

9.2

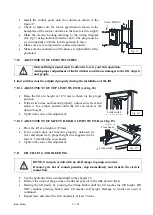

PERIODIC MAINTENANCE

Daily pre-

operation

Check hydraulic connections and hoses for leaks

Check safety lock audibly and visually while in operation

Check bolts, nuts and screws are tight

Every 1 month

Check all chain connections, pins and bolts to insure proper mounting

Check all arm pivot pins. Make sure they are properly secured

Check all lifting pads, replace if necessary

Check the hydraulic oil, fill or replace if necessary

Check hydraulic systems for proper operation

Every 12 months

Verify that all components and mechanisms are not damaged

Check the electrical system to verify that the motor, limit switch and

control panel operate properly (this work must be carried out by skilled

electricians)

empty the oil tank and change the hydraulic oil