Page 5

Step 7

Step 8

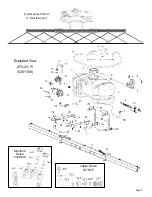

Assembly Procedure (ATV-25-71)

*** The Sprayer should now be ready for use ***

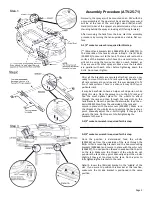

The pressure gauge (5167097) is located in the parts bag.

To install the gauge (See DETAIL Gauge), wrap some Teflon

tape or use some plumbers thread sealant over the threads

of the gauge, then start threading it into the (open) port

located on the manifold. Hand tighten securely.

** DO NOT OVER-TIGHTEN **

Screw the lid (5058188) onto the tank. Place the end of the

lanyard through the tab in the tank. (See DETAIL Lanyard).

This is so the lid can ‘hang’ off the tank when filling/rinsing

the tank out.

Lid Lanyard

Lanyard Connection Tab

DETAIL Lanyard

DETAIL Gauge

1/4” FPT

5167097

Manifold

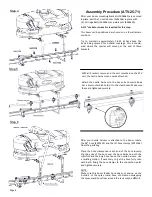

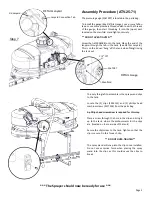

The only thing left to assemble is the spray wand clips

to the tank.

Locate the (2) clips (5053112) and (2) phillips head

machine screws (5117334) from the parts bag.

A phillips head screwdriver is required for this step

Place a screw through the hole in the clip and bring it

up to the tank, where the embossments for the clips

are (located on the rear side of the tank)

Secure the clip/screw to the tank. Tighten so that the

clip is secure. Do this for each clip.

** DO NOT OVER-TIGHTEN **

The spray wand will snap into the clips once installed.

Do not use excessive force when placing the spray

wand into the clips, as this could cause the clips to

break.