11

The specifi ed emissions values (vibration, noise)

– are used to compare machines.

– They are also used for making preliminary

estimates regarding vibration and noise loads

during operation.

– They represent the primary applications of the

power tool.

Increase possible for other applications, with oth-

er insertion tools or if not maintained adequately.

Take note of idling and downtimes of machine!

3

Power supply and start-up

The mains voltage must correspond to

the specifi cation on the rating plate.

The slide switch (1.2) serves as an On/Off switch

(I = ON, 0 = OFF).

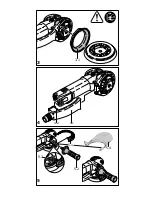

Only RO 150 FEQ:

See Fig. 2 for connection and

disconnection of the power cable.

Always switch the machine off before con-

necting or disconnecting the mains lead!

4 Electronics

The machine has full-wave electronics

with the following features:

Smooth start-up

The smooth start-up ensures the machine starts

up jolt-free.

Speed adjustment

You can regulate the speed steplessly between

3300 and 6800 rpm using the adjusting wheel (1.4).

This enables you to optimise the cutting speed to

suit the material.

Constant speed

The pre-selected speed remains constant whether

the machine is in operation or in neutral position.

Temperature control

If the motor temperature becomes too high, the

power supply and speed are reduced. The tool

then only runs with reduced power to enable

rapid cooling by means of the motor ventilation.

After cooling down, the tool accelerates again

automatically.

5 Machine

settings

Always remove the power supply plug

from the socket before carrying out any

work on the machine.

5.1 Sanding

motion

You can use the switch (1.1) to set two different

sanding motions.

The change can only be made when the

sanding pad is stationary, as the switch

is locked in place during operation for

reasons of safety.

Rotex rotary motion (coarse sanding, polishing)

The Rotex rotary motion is a combina-

tion of rotary and eccentric motions. This

position is selected for sanding with high

output (coarse sanding) and polishing.

Slide the switch (1.1) into the right position.

Eccentric motion (fi ne sanding)

This position is selected for sanding with

low output for a scratch-free surface (fi ne

sanding).

Press the switch (1.1) downwards and push it into

the left-hand position.

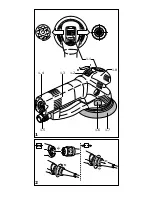

5.2

Sanding pad brake

The rubber collar (3.1) prevents the sanding

pad from revving up to maximum speed in an

uncontrolled manner during eccentric motion

(fi ne sanding). Because the collar wears down

in the course of time, it has to be replaced by a

new one (order no. 465 472) as soon as there is

any reduction in the braking effect. When fi tting

a new rubber collar (3.1), make sure it is in the

correct position.

5.3

Choice and installation of the sanding

disks

Choise of sanding disk

The appliance can be fi tted with three sanding

disks of different hardness depending on the

surface to be treated.

Hard

: coarse and fi ne sanding on surfaces. Sand-

ing at edges.

Soft:

universal for coarse and fi ne sanding for fl at

and curved surfaces.

Super-soft:

fi ne sanding on formed parts, curves,

radii. Do not use on edges!

Assembly

The FastFix system enables tool-free replacement

of the sanding pad:

- Set the switch (1.1) to the right, to the Rotex

rotary motion

- Press spindle stop (1.6),

- Turn the fi tted sanding pad from the spindle

(right-handed thread)

- Keep the spindle stop pressed down and screw

on the new sanding pad up to the stop (until

it can be turned no more). Make sure that the

rubber collar (3.1) is fi tted correctly when doing

this.