8

Installation

8.1

Pneumatic installation

NOTICE!

Loss of function due to contamination in the connections.

•

Keep ports and tubing lines free from dirt particles and foreign matter.

The use of a check valve prevents the payload from dropping in the event of a

sudden pressure drop.

The use of a one-way flow control valve also permits adjustment of the opening

and closing time.

•

Connect the compressed air supply to the supply ports.

Note the gripper type and gripping method (external/internal gripping).

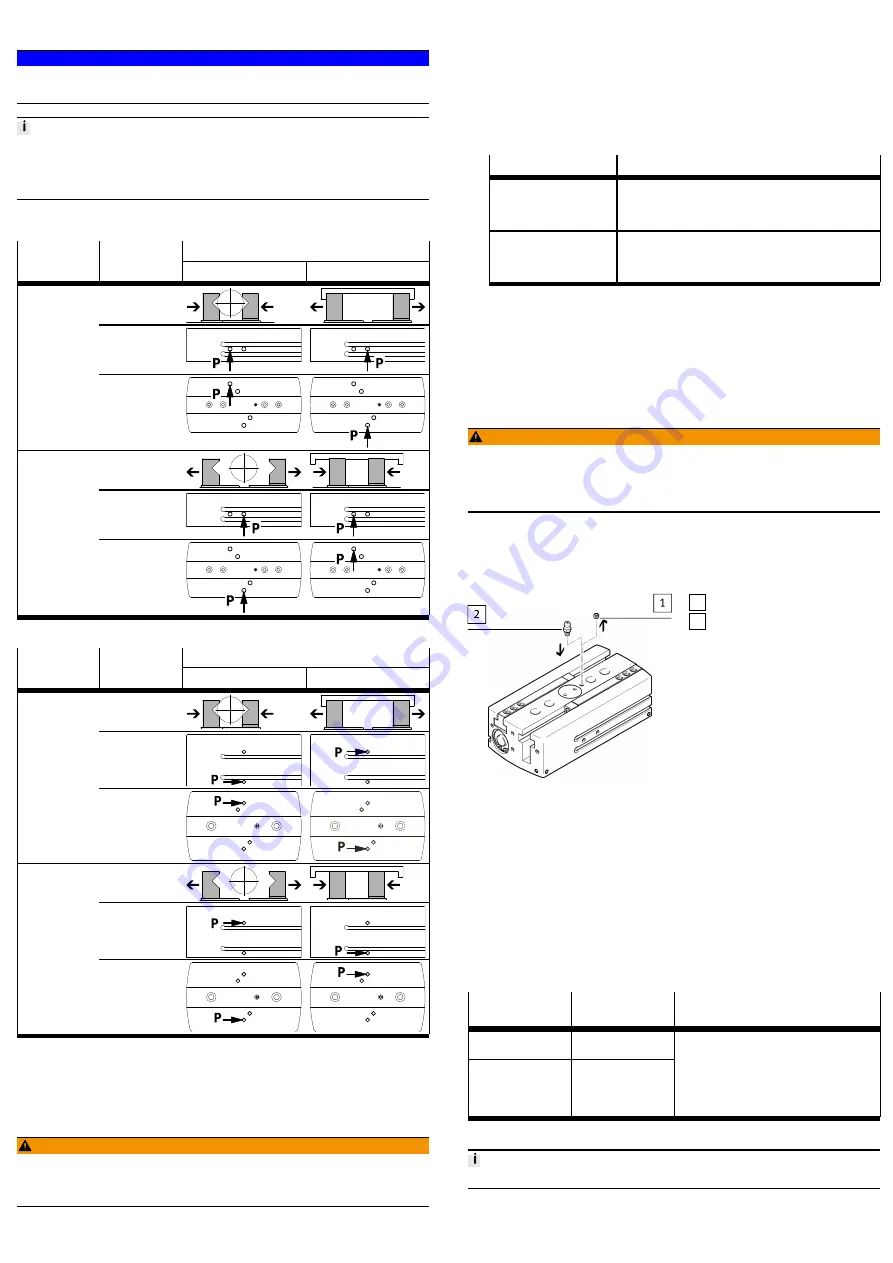

Gripping type

Function

Supply ports

external gripping

internal gripping

Gripping

side

Bottom

Releasing

side

Bottom

Tab. 5 Supply ports HGPL-B-14/25

Gripping type

Function

Supply ports

external gripping

internal gripping

Gripping

side

Bottom

Releasing

side

Bottom

Tab. 6 Supply ports HGPL-B-40/63

8.2

Electrical installation

•

Connect the proximity sensor.

Follow assembly instructions

è

9

Commissioning

WARNING!

Danger of crushing.

The gripper fingers could move unintentionally and crush body parts.

•

Do not reach into the movement range.

1. Pressurise gripper slowly.

2. Set the opening and closing time with an upstream one-way flow control

valve: screw in the flow control screw completely and then unscrew it one

turn.

3. Perform a test run without payload.

Check the following:

–

Allocation of supply ports

–

Reliable function of the proximity sensors (if installed)

–

Stop noise of the piston: the piston stop must be soft, that means not

audibly hard or metallic.

Piston stop

Insight/conclusion

soft

The gripper speed is correct or can be increased.

With upstream one-way flow control valve: unscrew the flow

control screw slightly.

è

The gripper speed increases.

hard/metallic

The gripper speed is too high. With an upstream one-way flow

control valve: screw in the flow control screw until the piston

stop is no longer audibly hard or metallic.

è

The gripper speed is reduced.

Tab. 7 Piston stop

4. Perform a test run with payload.

Ä

The gripper must hold the payload securely.

5. After successful test runs:

–

Remove payload or lock to prevent it from falling.

–

Exhaust the grippers.

10

Maintenance

10.1

Safety

WARNING!

Risk of injury due to unexpected movement of the gripper fingers or falling pay-

load.

•

Before exhausting: remove the payload at the gripper.

•

Disconnect gripper from the compressed air supply.

10.2

Mounting lubrication nipple

The lubrication nipple can be mounted on the top or bottom of the gripper.

The procedure is the same for mounting the lubrication nipple at the bottom of

the gripper.

1 Threaded pin M5

2 Lubrication nipple

Fig. 5 Mount the lubrication nipple (shown: top of gripper)

1. Unscrew the threaded pin on the top of the gripper (gripper jaw side) or on

the bottom of the gripper.

2. Screw in the included lubrication nipple (tightening torque: 0.7 Nm).

After the lubrication process (as required):

1. Unscrew and remove lubrication nipple.

2. Screw in threaded pin until it is flush.

10.3

Clean product

•

Clean the outside of the product with a soft cloth as required. Cleaning agents

include all non-abrasive media.

10.4

Lubricating guide elements

The maintenance interval depends on the ambient temperature when using the

gripper.

Ambient temper-

ature

Maintenance

interval

Maintenance work

>

20 … 60 °C

every 2 million switch-

ing cycles

³

5 … 20 °C

every 5 million switch-

ing cycles

On the mounted lubrication nipple on the top or

bottom of the gripper: lubricate the guide ele-

ments.

In the delivery status the access holes are sealed

with threaded pins

è

10.2 Mounting lubrication nipple.

Approved lubricant

è

Tab. 8 Maintenance interval and maintenance work

Information on spare parts and accessories

è