2. Fasten motor mounting kit, observe instruction manual

3. Fasten the motor without tension. Support large and heavy motors.

Connect motor cables only on completion of mounting.

6.4

Mounting the cylinder

High mechanical loads on the mounting connections

If high parallel torques are applied to the drive system at the same time, this leads

to high mechanical loads at the mounting interfaces.

• The foot mounting HNC, CRHNC should only be used in combination with the

profile mounting EAHF.

• In the case of an inclined or horizontal mounting position with direct fastening

or flange mounting EAHH-V2, the drive system must also be supported near

the motor mounting.

Requirement

–

No collision with mounting and sensor components in the movement space of

the attachment component.

–

Sufficient space to reach maintenance interfaces.

–

Sufficient space for reaching and mounting the pressure compensation port.

–

Flat mounting surface maximum 0.2 mm over the stroke length of the bearing

surface.

–

No distortion or bending when installing the product.

1. Select mounting attachments

2. Place the mounting attachments on the support points.

3. Tighten retaining screws.

Observe the maximum tightening torque and screw-in depth.

For additional information, contact your local Festo Service.

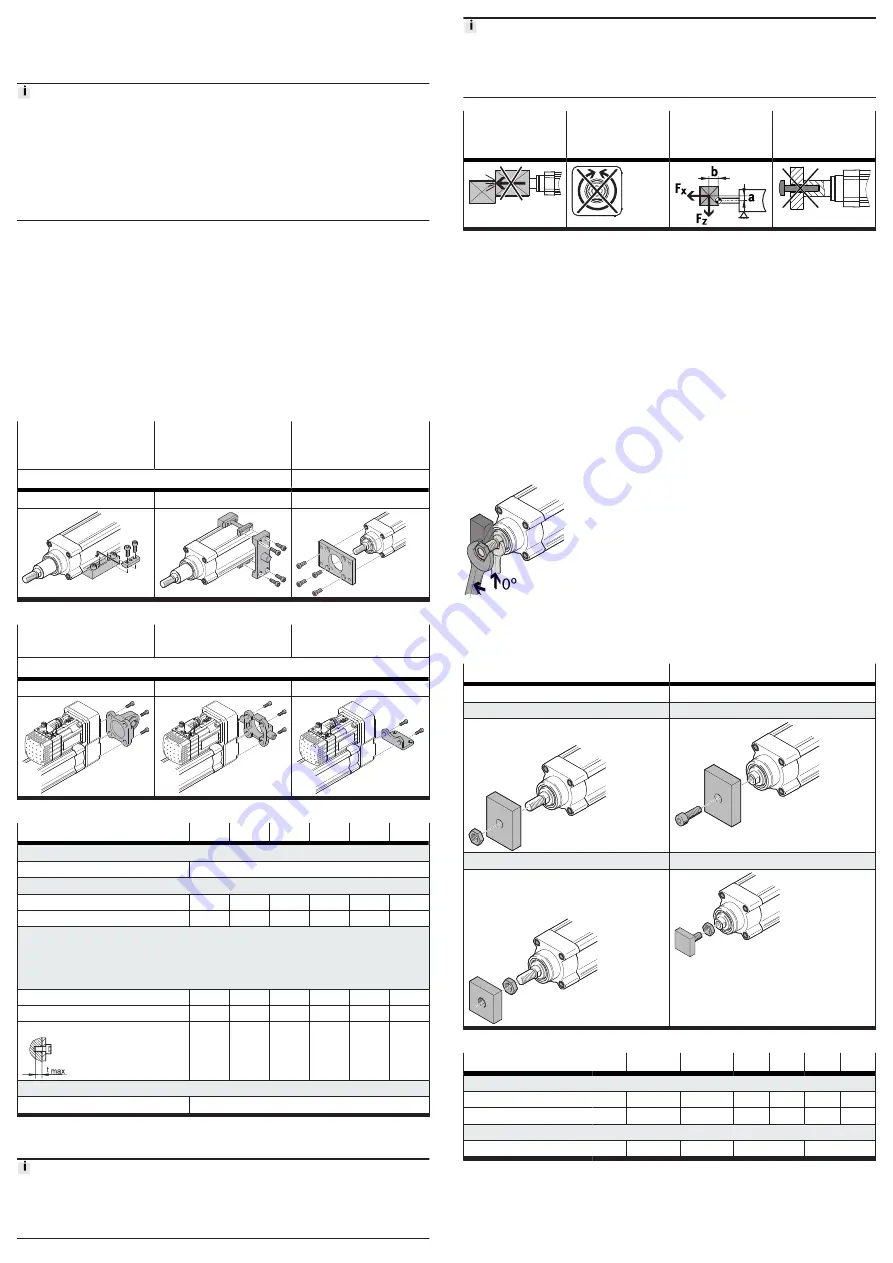

Profile mounting

EAHF-V2

Trunnion flange

mounting kit DAMT-V1

Direct fastening

Flange mounting

EAHH-V2

Profile

Bearing cap

Mounting via profile

Mounting via thread

Mounting via thread

Tab. 3: Overview of mounting components for bearing caps and profile

Swivel flange DAMS,

SNC..., CRSNCS

Trunnion flange ZNCF,

CRZNG

Foot mounting HNC,

CRHNC

Parallel kit

Mounting via thread

Mounting via thread

Mounting via thread

Tab. 4: Overview of mounting components for parallel kit

Size

32

40

50

63

80

100

Profile mounting EAHF-V2

Screw

Trunnion flange mounting kit DAMT-V1

Screw

M5

M6

M6

M8

M8

M8

Max. tightening torque

[Nm]

4

+1

8

+1

8

+2

18

+2

28

+2

28

+2

Direct fastening

Flange mounting EAHH-V2

Foot mounting HNC, CRHNC

Swivel flange DAMS (not ESBF-BF-32)

Trunnion flange ZNCF, CRZNG

Screw

M6

M6

M8

M8

M10

M10

Max. tightening torque

[Nm]

6

6

12

12

25

25

Max. screw-in depth t

max

[mm]

16

16

17

17

17

17

Swivel flange SNC..., CRSNCS

Screw

Tab. 5: Information for mounting components

6.5

Mounting the attachment component

Torque on the Piston Rod

During commissioning and operation, the piston rod may only be operated

without torque.

If external torques occur, an external guide must be used.

Mounting the attachment component on the piston rod

When mounting the attachment component, do not exceed the maximum torque

of the piston rod. The maximum torque of the piston rod may only be used for a

short time during mounting

Tab. 8 Information on attachment components.

Collision-free

Torque-free

Centre of gravity

and tilting

moment

Max. screw-in

depth

Tab. 6: Requirement for attachment components

Requirement:

–

No collision with mounting and sensor components in the movement space of

the attachment component.

–

No transverse load or torque on the piston rod.

Absorb external forces and torques via an external guide.

–

Minimise tilting torque by the Fx and Fz forces. Short lever arms a and b from

the piston rod

to the centre of gravity of the attachment

–

The maximum screw-in depth of the retaining screws is not exceeded.

1. Select accessories

2. Screw the lock nut onto the male thread of the piston rod or attachment

component.

3. Rotate or place the attachment component on the piston rod.

4. Tighten retaining screws or lock nut.

The tightening torque must not act on the piston rod. Counterhold with a

suitable tool on the spanner flat of the piston rod.

Observe the maximum tightening torque and screw-in depth.

Fig. 2: Torque-free mounting

When using an additional external guide, ensure that the electric cylinder and

piston rod are aligned exactly parallel.

ESBF-...

ESBF-...-F

Mounting via male thread

Mounting via female thread

With nut

With screw

–

Guide unit EAGF

With lock nut

With lock nut

–

Rod eye SGS, CRSGS

–

Rod clevis SG, CRSG

–

Coupling piece KSZ

–

Self-aligning rod coupler FK; CRFK

Tab. 7: Overview of attachment components

Size

32

40

50

63

80

100

Piston rod

Width across flats

ß

[mm]

10

13

17

17

22

22

Max. torque

[Nm]

2.4

6.4

12

15

31

53

Piston rod with male thread ESBF -...

Nut, lock nut

M10x1.25

M12x1.25

M16x1.5

M20x1.5