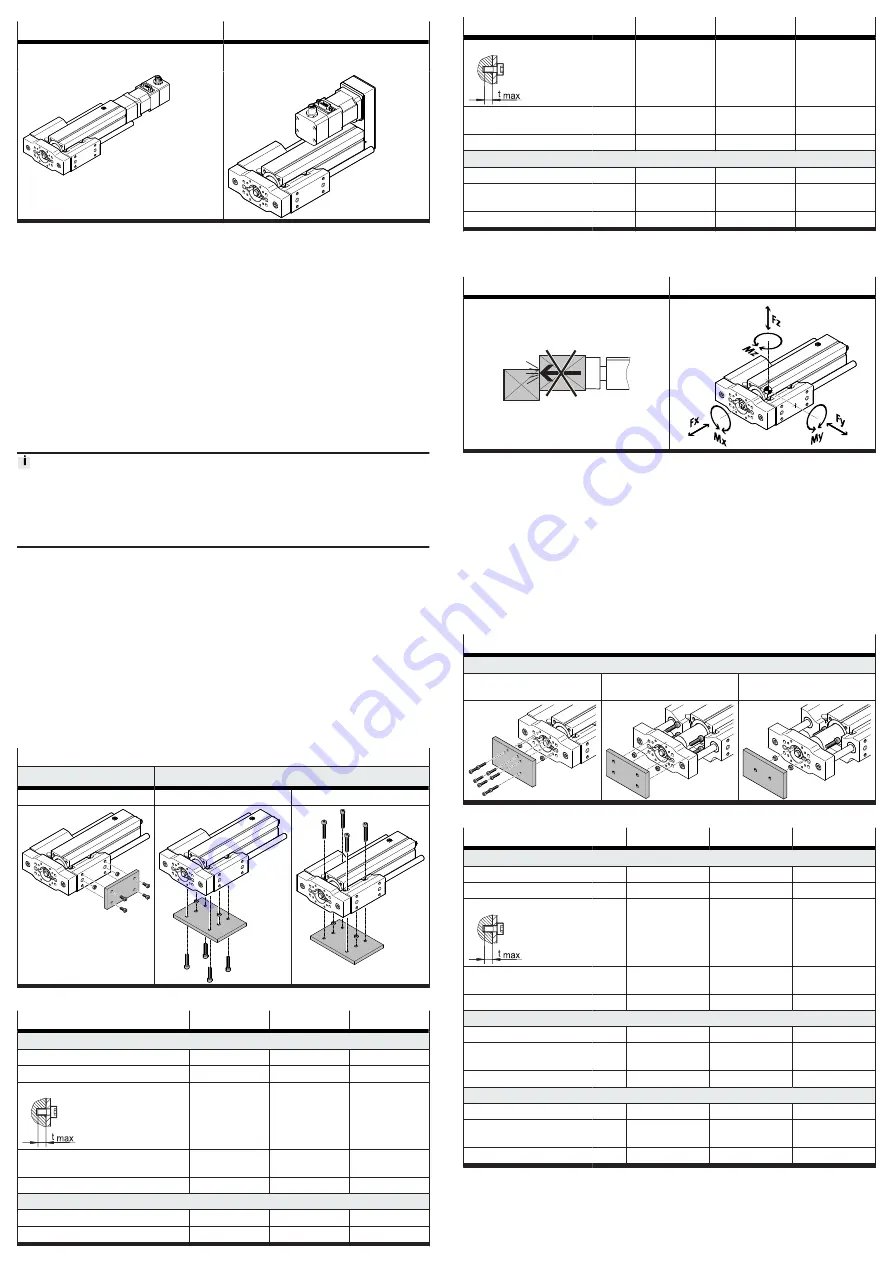

Axial kit EAMM-A

Parallel kit EAMM-U

Mount the motor only on a side without a guide

rod.

Tab. 2: Overview of motor mountings

Requirement

–

Only loosen screws or threaded pins that are described in the directions in the

instruction manuals.

–

Sufficient space for reaching and mounting the sealing air connection

1. Select the motor and motor mounting kit from

Festo

If other motors are used: observe the critical limits for forces, torques and

velocities.

2. Fasten motor mounting kit, observe instruction manual

3. Fasten the motor without tension. Support large and heavy motors.

Connect motor cables only on completion of mounting.

6.4

Fasten cylinder with guide

High mechanical loads on the mounting connections

If high parallel torques are applied to the drive system at the same time, this will

result in high mechanical loads at the mounting interfaces.

• If the mounting position is inclined or horizontal with direct fastening, the drive

system will require additional support near the motor mounting.

Requirement

–

No collision in the range of motion of the attachment component with motor,

mounting components and sensor components.

–

Sufficient space to reach maintenance interfaces.

–

Sufficient space for reaching and mounting the sealing air connection.

–

Flat mounting surface maximum 0.2 mm over the stroke length of the bearing

surface.

–

No distortion or bending when installing the product.

1. Select mounting attachments

2. Place the mounting attachments on the support points.

3. Tighten retaining screws.

Observe the maximum tightening torque and screw-in depth.

For additional information, contact your local Festo Service.

Direct fastening

Guide housing, lateral

Guide housing, bottom

Mounting via thread

Mounting via thread

Mounting via through-hole

Tab. 3: Overview of mounting components for profile

Size

32

45

60

Direct fastening, lateral via thread

Screw

M5

M5

M5

Max. tightening torque

[Nm]

5.2

5.2

5.2

Max. screw-in depth t

max

[mm]

8.5

12

10

Centring hole and centring

element

[mm]

Æ

7

Æ

7

Æ

7

Centring hole tolerance

H8

H8

H8

Direct fastening, bottom via thread

Screw

M5

M5

M5

Max. tightening torque

[Nm]

5.2

5.2

5.2

Size

32

45

60

Max. screw-in depth t

max

[mm]

12

12

10

Centring hole and centring

element

[mm]

Æ

7

Æ

7

Æ

7

Centring hole tolerance

H8

H8

H8

Direct fastening, bottom via through-hole

Screw

M4

M5

M6

Centring hole and centring

element

[mm]

Æ

4

Æ

5

Æ

7

Centring hole tolerance

H8

H8

H8

Tab. 4: Information for mounting components

6.5

Mounting attachment component

Collision-free

Guide load

Tab. 5: Requirement for attachment components

Requirement:

–

No collision in the range of motion of the attachment component with motor,

mounting components and sensor components.

–

Minimise guide load. Short lever arms from the centre of the yoke plate

to the force application points and centre of gravity of the attachment compo-

nents.

1. Select accessories

2. Place centring components in centring holes.

3. Position attachment component on the yoke plate.

4. Tighten retaining screws.

Observe the maximum tightening torque and screw-in depth.

Direct fastening

Yoke plate

Mounting via thread

Mounting via through-hole,

outside

Mounting via through-hole,

inside

Tab. 6: Overview of attachment components

Size

32

45

60

Direct fastening via thread

Screw

M3

M3

M4

Max. tightening torque

[Nm]

1.2

1.2

2.8

Max. screw-in depth t

max

[mm]

7

7

9

Centring hole and centring

element

[mm]

Æ

7

Æ

7

Æ

7

Centring hole tolerance

H8

H8

H8

Direct fastening via through-hole, outside

Screw

M4

M5

M5

Centring hole and centring

element

Æ

7

Æ

7

Æ

7

Centring hole tolerance

H8

H8

H8

Direct fastening via through-hole, inside

Screw

M4

M5

M5

Centring hole and centring

element

Æ

7

Æ

7

Æ

7

Centring hole tolerance

H8

H8

H8

Tab. 7: Information on attachment components