7.3

Mounting the motor

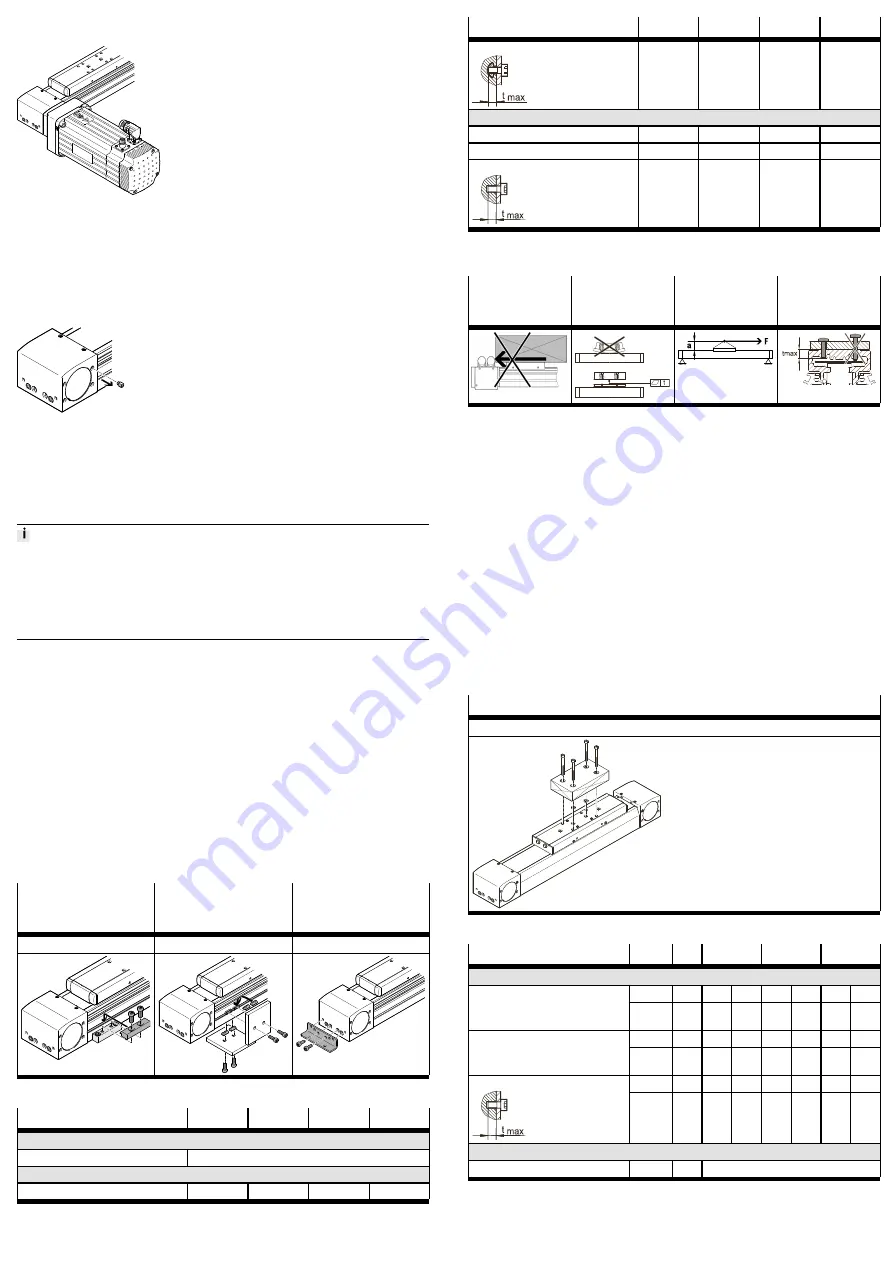

Fig. 3 Motor mounting

Only loosen screws or threaded pins that are described in the directions in the

instruction manual.

1. Select the motor and motor mounting kit from

Festo

è

When using other motors: observe the critical limits for forces, torques and

velocities.

Fig. 4 Remove the plug screw

2. Remove the sealing air plug screw from the threaded hole.

3. Fasten motor mounting kit, observe instructions

è

4. Fasten the motor without tension. Support large and heavy motors.

Connect motor cables only on completion of mounting.

7.4

Fasten axis

High mechanical loads on the mounting connections

If the mounting position of the motor and the mounting component simultan

eously cause high rectified torques around the longitudinal axis, this leads to high

mechanical loads at the mounting interfaces.

•

The foot mounting HPE should only be used in combination with the profile

mounting MUE or the slot nuts NST.

Requirement

–

No collision in the movement space of the attachment component with motor,

mounting and sensor components.

–

Sufficient space to reach maintenance interfaces.

–

Flatness of the mounting surface of 0.05% of the stroke length or max.

0.5 mm over the stroke length of the bearing surface.

–

Required support points lie within the specified support

distances

è

–

No distortion or bending when installing the product.

1. Select mounting attachments

è

2. Place the mounting attachments on the support points.

3. Tighten retaining screws.

Observe max. tightening torque and max. screwin depth.

For area and 3dimensional gantries, pay attention to parallelism, product height

and alignment of the axes.

For additional information, contact your local Festo Service.

Profile mounting MUE

(ELGA-...-...MA)

Slot nut NST For mount-

ing slot

(ELGA-...-...NM)

Foot mounting HPE

(ELGA-...-MF)

Mounting via profile groove

Mounting via profile groove

Mounting via thread

Tab. 1 Overview of mounting components

Size

70

80

120

150

Profile mounting MUE

Screw

Instruction manual

è

Slot nut NST

Screw (side/bottom)

M5

M5

M6

M6

Size

70

80

120

150

max. screwin depth t

max

[mm]

6

6

12

12

Foot mounting HPE

Screw

M5

M5

M8

M8

max. tightening torque

[Nm]

5.9

5.9

24

24

max. screwin depth t

max

[mm]

10

10

16

18

Tab. 2 Information on mounting attachments

7.5

Mounting attachment component

Collision-free

Evenness

Centre of gravity

and tilting

moment

Max. screw-in

depth

Tab. 3 Requirement for attachment element

Requirement

–

No collision in the movement space of the attachment component with motor,

mounting and sensor components.

–

Flatness of the mounting surface of the mounting component of 0.01 mm

(recirculating ball bearing guide KF/roller guide RF) or 0.03 mm (plainbearing

guide G) over the slide surface.

–

Position of the centre of gravity and tilting moment (force F parallel to the axis

of motion) of the attachment component centrally on the slide and close to

the slide surface (short lever arm a).

–

The maximum screwin depth of the retaining screws is not exceeded.

1. Select accessories

è

2. Place centring components in centring holes.

3. Position the attachment component on the slide.

4. Tighten retaining screws.

Observe max. tightening torque and max. screwin depth.

When using an additional external guide, ensure exact parallelism and alignment

of the axes and guide.

Recommendation: use guide fixings with tolerance compensation.

Direct mounting

Mounting via thread

Tab. 4 Overview of attachment component

Size

70

80

120

150

Direct mounting

G/RF

M5

M5

M6

M5

M6

M6

M8

Screw

KF

M5;

M6

M5

M6

M5

M6

M6

M8

G/RF

5.9

5.9

9.9

5.9

9.9

9.9

24

Tightening torque

[Nm]

KF

5.9;

9.9

5.9

9.9

5.9

9.9

9.9

24

G/RF

7.5

9

9.7

9.7

12.6

11

10.7

max. screwin depth t

max

[mm]

KF

7.5;

5.4

9

9.7

9.7

12.6

11

10.7

Centring (bore tolerance H7)

Centring pins

[mm]

G/KF

Æ

5

–