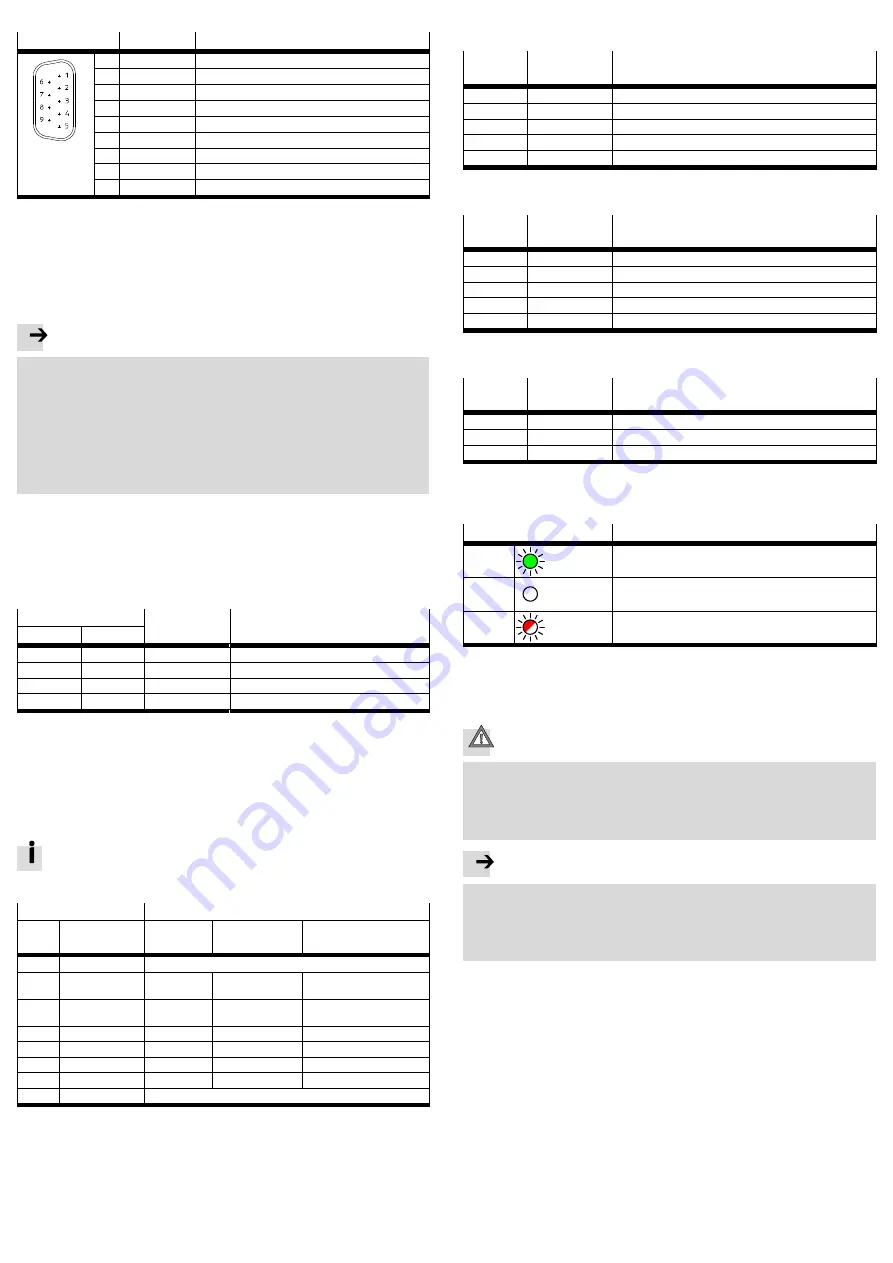

3.2 Fieldbus interface X6

Pin

Signal

Explanation

1

N.c.

Not connected

2

CANBus signal (dominant low)

3

CAN_GND

CAN Ground

4

N.c.

Not connected

5

CAN_SHLD

Functional earth

6

CAN_GND

CAN Ground (optional)

7

CAN_H

CANBus signal (dominant high)

8

N.c.

Not connected

9

N.c.

Not connected

1)

If the controller is at the end of the cable:

Connect pin 2 and pin 7 using a terminating resistor (120 ohms/0.25 W).

Appropriate CAN bus plugs (adapters) from Festo

è

www.festo.com/catalogue

Fig. 4

Fieldbus interface X6

3.3 USB interface X7

The USB interface enables external storage media to be connected using USB plug

type A.

Note

Malfunction due to undefined switching statuses of the electronics.

If a USB hard disk without its own power supply is used, the maximum permitted

current consumption can be exceeded, e.g. when the USB hard disk is running up.

Controller CECC-D and CECC-LK:

Use only storage media with current consumption

100 mA.

Controller CECC-S:

USB storage medium and encoder are supplied from a common power source.

Use USB storage medium and encoder whose total current consumption

500mA.

3.4 Ethernet interface X8

The Ethernet interface

1

è

Fig. 2 enables connection of a programming unit, PC

or operator unit to the controller.

The Ethernet interface is designed as an RJ45 socket.

3.5 Serial interfaces X12 and X13 (CECC-S)

Pin

Designation/

signal

Explanation

RS232-1

RS232-2

X12.1

X13.1

G

Data reference potential

X12.2

X13.2

TX

Transmitted data

X12.3

X13.3

RX

Received data

X12.4

X13.4

S

Shield, functional earth

Fig. 5

Serial interface modules X12 and X13

3.6 Multiple interface X14 (CECC-S)

The controller CECC-S has a combined interface with the following connection

options:

– Encoder (ENC, RS422-based encoders only)

– RS422

– RS485

Simultaneous use of these connection options is not possible.

Configure and use only one of the three connection options with

CODESYS.

Connection option

Explanation

Pin

Designation/

signal

Encoder

RS422

RS485

X14.1

G

Load

X14.2

A+

Track A+

Transmitted

data+

Transmitted/received

data+

X14.3

A–

Track A–

Transmitted

data-

Transmitted/received

data–

X14.4

B+

Track B+

N.c.

X14.5

B–

Track B–

Received data–

N.c.

X14.6

N+

Zero track+

N.c.

N.c.

X14.7

N–

Zero track–

N.c.

N.c.

X14.8

S

Shield, functional earth

1)

If the controller is at the end of the cable:

Connect pin X14.2 and pin X14.3 using a terminating resistor (120 ohms/0.25 W).

Connect pins X14.4 and X14.5 using a terminating resistor (120 ohms/0.25 W).

Fig. 6

Multiple interface X14

3.7 Communication interfaces IO-Link

4 x IO-Link Master Port X12…X15 (CECC-LK: IOL-M...)

Pin

Designation/

signal

Explanation

X12 … X15.1

L+

Operating voltage supply (24 V)

X12 … X15.2

C/Q

Data communication

X12 … X15.3

L–

Operating voltage supply (0 V)

X12 … X15.4

24

Load voltage supply (24 V) from X11

X12 … X15.5

0

Load voltage supply (0 V) from X11

Fig. 7

IO-Link Master Port X12…X15

1 x IO-Link Master Port X15 (CECC-S: IOL-M)

Pin

Designation/

signal

Explanation

X15.1

L+

Operating voltage supply (24 V)

X15.2

C/Q

Data communication

X15.3

L–

Operating voltage supply (0 V)

X15.4

24

Load voltage supply (24 V) from X11

X15.5

0

Load voltage supply (0 V) from X11

Fig. 8

IO-Link Master Port X15

1 x IO-Link Device Port X16 (CECC-LK and CECC-S: IOL-D)

Pin

Designation/

signal

Explanation

X16.1

L+

Operating voltage supply (24 V) from X1

X16.2

C/Q

Data communication

X16.3

L–

Operating voltage supply (0 V) from X1

Fig. 9

IO-Link Device Port X16

3.8 LED indicators

The following LED indicators signal the normal operating status of the controller:

LED

Meaning

Run

Lights up

green

Program running

Error

Off

No error

Net

Flashes

red

Controller has been identified in the network

Fig. 10 LED indicators

All LED indicators

è

4

Power supply

Caution

Risk of injury due to electric shock

For the electric power supply, use only PELV circuits that ensure a reliable

electric disconnection from the mains network.

IEC60204-1/EN60204-1 to be screwed in.

Always connect all circuits for operating and load voltage supply.

Note

The product may only be supplied from a single power source that fulfils the require

ments of energy-limited circuits in conformity with IEC/EN/UL/CSA 61010-1 or of

an energy-limited voltage source (limited power sourse, LPS) in conformity with

IEC/EN/UL/CSA60950-1 or IEC/EN/UL/CSA 62368-1 or of a class 2 circuit in con

formity with NEC or CEC.