Connection Buffer/Feeder

Bushing

Pin

Signal

O/1

24 V DC/Box ready

–

Reference voltage for sensors (switched off in Stop status)

–

Operating readiness status

–

Control for transport device (e.g. conveyor)

O/2

Feeder

Control of the small parts conveyor

(e.g. upstream conveyor pot)

3

GND

Reference voltage for sensors

I/4

Buffer

Buffer zone sensor 1

5

Do not connect

Tab. 5: Connection Buffer/Feeder

Connection Ethernet

Bushing

1)

Pin

Signal

1

TD+

Transmitted data +

2

RD+

Received data +

3

TD–

Transmitted data –

4

RD–

Received data –

Metal covering

Shielding (Shield)

1) M12, D-coded

Tab. 6: Connection Ethernet

Connection Encoder

Bushing

Pin

Signal

Interface for rotary pulse encoder as per RS 485 specification

1

A+

2

n.c.

3

B+

4

A–

5

B–

6

5 V power supply

1)

7

GND

8

n.c.

1) Maximum load 180 mA

Tab. 7: Connection Encoder

4.2

Function

The product enables the optical (contactless) positioning and quality inspection

of conveyed parts and it precisely controls the actuator technology for sorting

the inspected parts and parts assigned to the result groups (tracking, ejection of

parts, etc.).

5

Assembly

CAUTION

Glare and eye irritation.

With regard to the blue light hazard, the product exceeds the limit values of the

Freie Gruppe according to DIN EN 62471:2009-03. Therefore, an assignment to

risk group 1 applies for the blue light hazard. Looking at the light source for a long

or prolonged period can dazzle your eyes and cause irritation.

Take measures to prevent eye exposure:

• Do not remove any housing parts.

• Only mount or remove the prism support when the power supply is switched

off.

• Mount the product only in its original state with closed, intact housing.

• Only assemble or disassemble the product when it is switched off.

• Mount the product in such a way that direct view into the light beam is not

possible.

• Also take measures to ensure that if the light beam is reflected off mirrored

or reflective objects, it does not pose a hazard, for example, by providing

screening.

• Do not stare directly into the light beam and do not direct the beam into the

eyes of other people.

Ordinary light sources are divergent, i.e. the illuminated area becomes larger as

the distance from the light source increases. As a result, the risk of eye injury

decreases as the distance from the light source increases. However, because the

product uses parallel light, the risk of eye injury is not reduced as the distance

increases; this applies to both looking directly at the beam and looking into the

beam via a reflective surface.

Installation location

Please note the following ambient conditions in particular:

–

Low vibration installation

–

Stable mechanical mounting

–

Clean ambient air: oil-free, no paint mist, no sanding dust

–

Screening of external light influences, external heat and extreme magnetic

fields (e.g. due to induction furnaces).

–

Mounting as cool and vertical as possible

This will ensure optimal inspection results and a long service life for the device.

Transporting device

In order to ensure a reliable and reproducible test result, the transporting device

used should fulfill the following requirements:

–

Use a high-grade transporting system which conveys the parts at a constant

speed.

–

Ensure that the parts are stable, e.g. by using mechanical devices.

–

Ensure smooth transfer of parts from the small parts conveyor to the trans-

porting device and that the transporting device is mechanically decoupled from

the small parts conveyor.

–

Also use mechanical devices to transfer parts securely from the transporting

device to the buffer zone (e.g. drop pipe, slide, chute) of the downstream

machine to prevent changes in the orientation of parts.

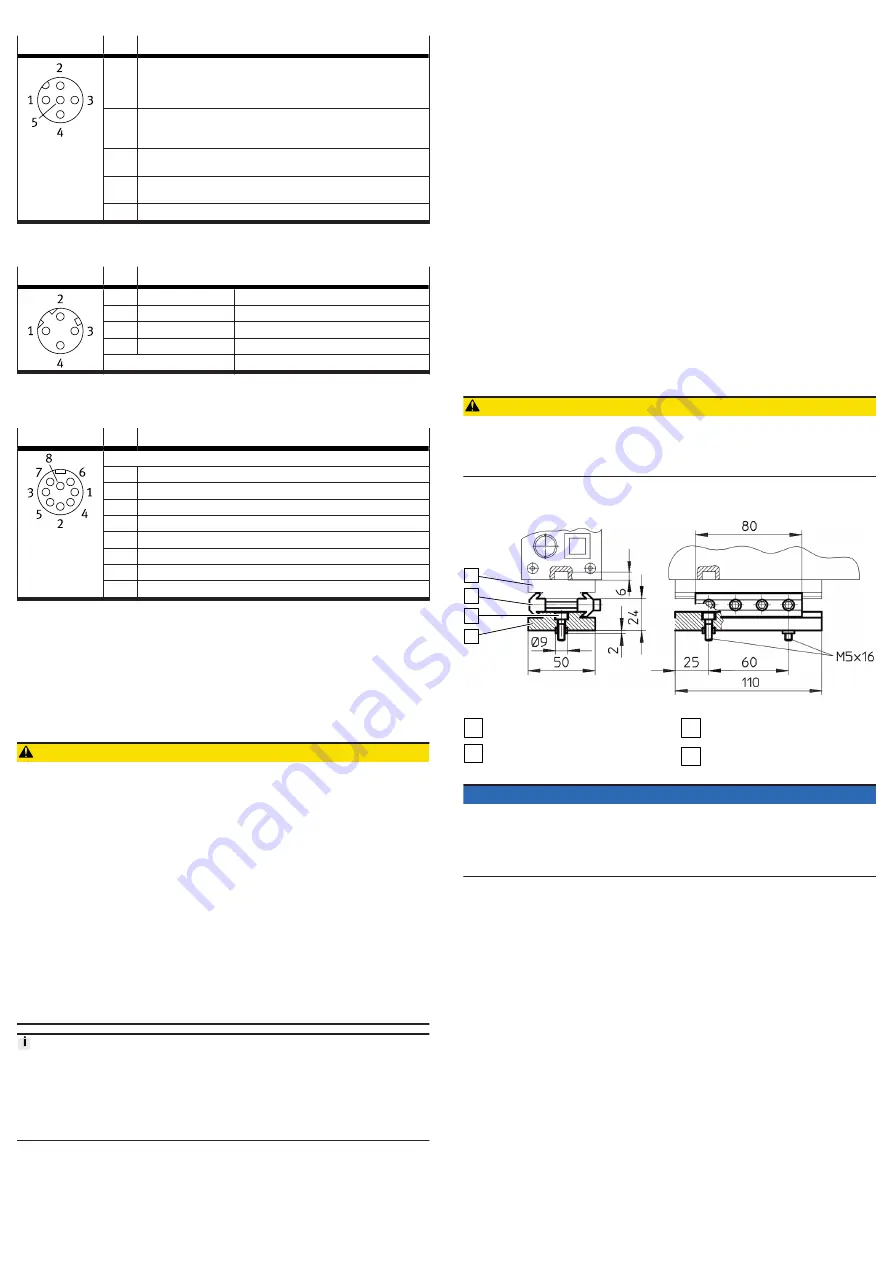

Mounting

A mounting profile with a dovetail guide is installed on the side of the product.

If the product is mounted from the other side, the mounting profile must be

dismantled and fixed on the opposite side.

CAUTION

Damage to components.

• Modify the product only in a clean environment.

• Use suitable screws. The screw-in depth in the device is limited to a maximum

of 6 mm.

The connection kit HMSV-12 is available as an accessory

2

1

3

4

Fig. 3: Mounting with connection kit HMSV-12

1

Mounting profile of the CHB-CN

2

Clamping elements with 4 M5x45

socket head screws

3

2 M5x16 socket head screws with

centring sleeves

4

Adapter plate

NOTICE

In order that a reliable test result can be achieved, the glass surfaces on the prism

supports must not be scratched or dirty:

• Mount the product so that passing parts do not touch the glass surfaces.

• Ensure that the parts are stable, e.g. with mechanical devices.

• Clean the glass surfaces as required.

When mounting the product above the transport device, note the following:

–

Attach the product to the transport device to form a stable unit.

–

Keep the camera's field of view clear.

–

Do not cover the optical channel with the transport device.

The product has excellent imaging properties over the entire working space. The

contrast of the image is optimised for very fine details on the sensor side.

–

To achieve maximum contrast for small details, mount the product so the

objects pass as close as possible to the prism support on the sensor side. This

is the side with the Start/Stop illuminated pushbutton.