24

GN3

MINIMUM VALUE

MAXIMUM VALUE

X

°

C

X

°

C

26

30

12

80

24

40

14

70

21

50

17

60

19

60

19

50

16

70

22

40

INSPECTIONS

ADJUSTEMENTS

Before initial ignition

Before initial ignition, it is advisable to check that:

a) the system has been filled at the correct pressure and

is well vented;

b) there are no water or fuel leaks;

c) the electrical power supply is correct;

d) the entire fumes duct has been correctly built, that it is

not too near and does not pass through inflammable

parts;

e) that there are no inflammable substances near the

appliance;

f) that the burner is proportional to boiler capacity;

g) the water on-off valves are open.

Burner

Burners fuelled with heating oil or gas, with blown air for

pressurized furnaces, can all be used so long as their

operative characteristics are suitable for the size of the

boiler furnace and its overpressure. The burner must be

chosen according to the Manufacturer’s instructions, in

compliance with fuel consumptions, pressures and the

length of the combustion chamber.

Burners with two flames must have a primary flame

corresponding to at least 50% of the boiler rating.

Boiler efficiency and correct burner operation particularly

depend on accurate adjustments.

NOTE:

Before starting the boiler, always check that the burner

door and smokebox are tight.

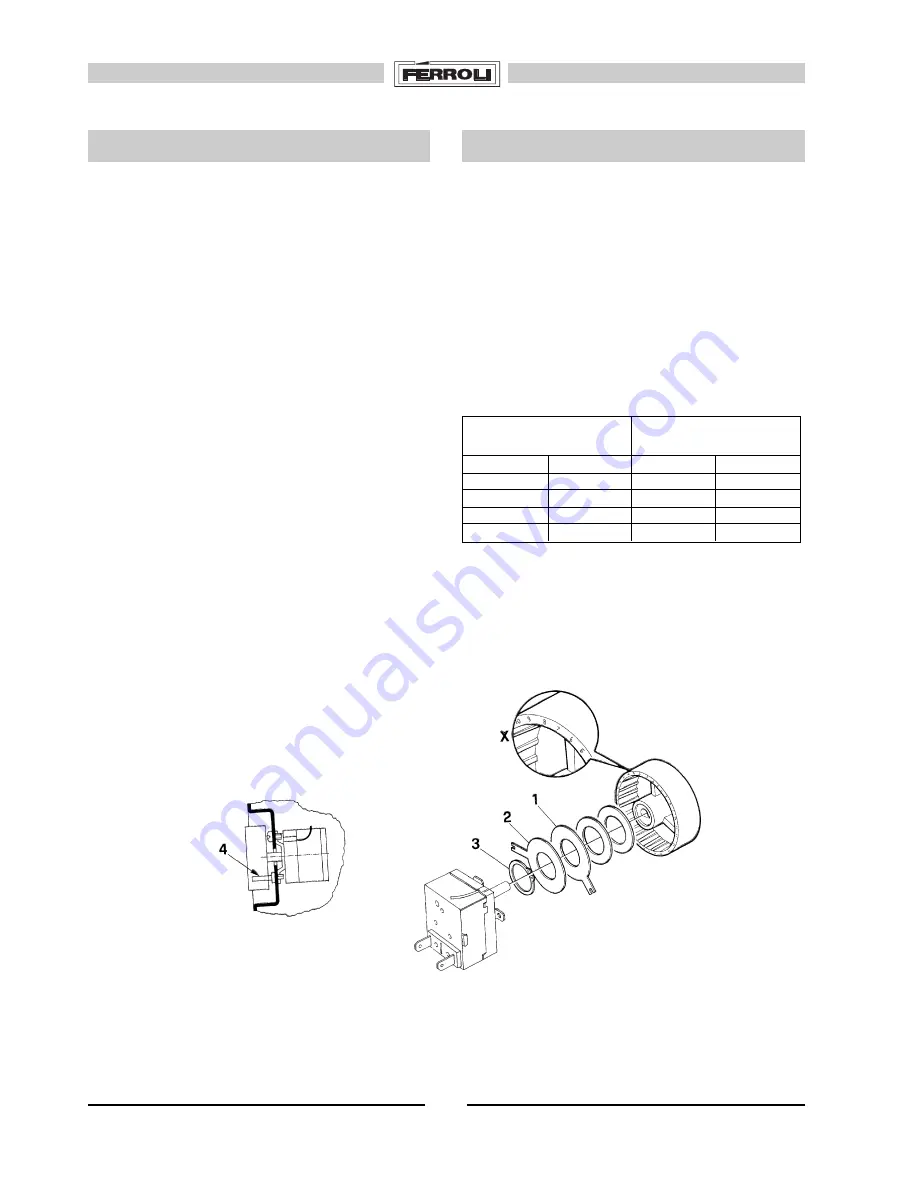

Thermostat positioning (fig. 51)

The thermostats are preset in the factory to a minimum

value of 30

°

C and a maximum value of 90

°

C. Proceed in

the following way to vary the regulating range of these

limit values:

a) Remove the thermostat knob.

b) Demount locking circlip 3 and stops 1 and 2.

c) Re-position stops 1 and 2 in their relative housings

marked “X”, corresponding to the required temperature

range (see table).

d) Remount the knob on the thermostat, checking that

prong 4 is between the two knob stops.

Fig. 51