Supplied By www.heating spares.co Tel. 0161 620 6677

23

DOMINA F 24 - 30 E

FERELLA F 24 - 30 MEL

MILOS AIR COMPACT E

Version - 09.2002

2.5 Fume circuit

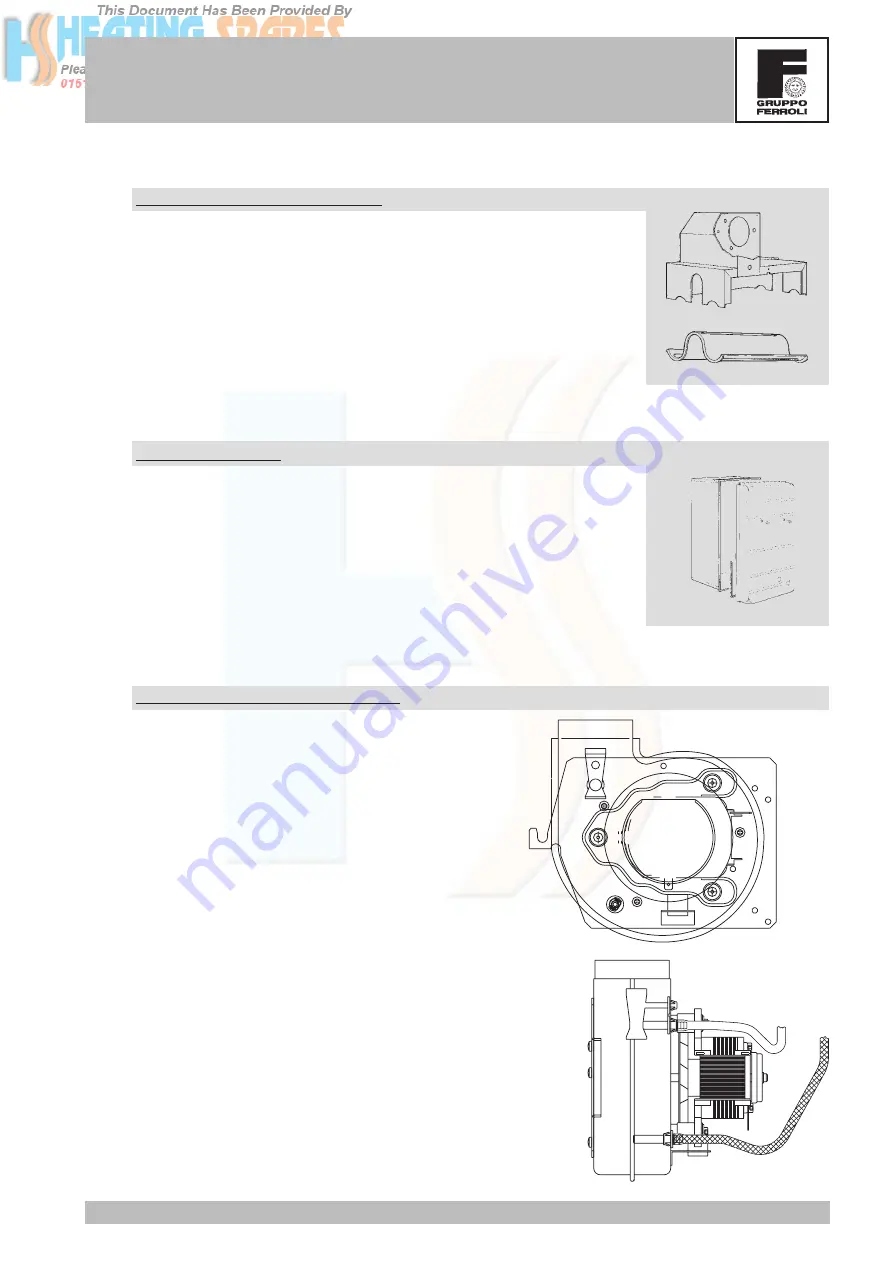

Fume deflector and manifold

All forced-flow boilers have a fume deflector above the exchanger whose

main task is to make the secondary air crossing the burners uniform, making

the flame homogeneous and stable. The fumes then reach a fume manifold

whose job is to make them move on to the fan.

Airtight chamber

Its task is to isolate the products of combustion from the area surrounding

the boiler. The airtight chamber contains all the components involved in the

fume routing. The wires and pipes coming out of its lower portion are

insulated with silicone seals, while its upper portion is fitted for hooking up

with the flues. The cover is sealed off with a porous plate and is fitted with

two plugs for using a probe to analyse the fumes and combustion air.

Fan and pressure switch points

Powered at 230V/50Hz by the card (X6 - 7/8), the fan has

the job of expelling the products of combustion from the

fume chamber. A plate is normally placed above the

exchanger to act as a deflector, make the incoming air

from the bottom of the burner uniform, make the flame

stable and obtain the required air/gas ratio. In order to

make sure the fan works properly, there are two pressure

points inside it. The first one detects a static pressure

signal that is positive, the second one detects a dynamic

pressure signal via an appropriate Venturi tube, which

is negative. With the difference in pressure detected by

the two test points it is possible to check whether the

fumes are adequately evacuated.