23

INDUSTRIE

Over ride

By pressing the over ride button (

E

) the timer programme is over ridden ie, if programme is in OFF time it will

come ON and if in ON time will go OFF.

The timer will revert back to it set programme on reaching the next ON or OFF time.

When the programme is on over ride the sign will be shown in the display window (

B

).

Reset Button

By the use of a pencil the reset button can be pushed (

R

). This will clear all programmes apart from those factory

pre set.

Reset is only possible with switch (A) in set Clock position!

x

8.8

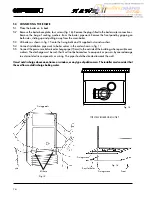

REMOVAL OF THE CLOCK

a)

Refer to section 1, items a, c, d, f and j.

b)

Disconnect the electrical connections to the time clock.

c)

Remove the time clock from the control panel (fig. 43).

d)

Re-assemble in reverse order (refer to fig. 43 for replacement of the time clock).