5

1.3 Technical data

Trademark: C24H

Manufacturer: Novum-Fég F

ű

téstechnikai és készülékgyártó Kft.

Type: B

11BS

Type of gas: II

2HS3B/P

Allowed maximum operating pressure: 3 bars

Allowed maximum heating water temperature: 90 ºC

Type of gas: „H”

natural

gas „S”

natural

gas Propane gas

Joint gas pressure:

25 mbar

25 mbar

30 mbar

Ø of burner nozzles (mm)

1,18 1,28 0,68

Ø of pilot burner:

0,3 0,3 0,2

Nominal heating capacity (kW):

24 18.3 24

Nominal heating load (Kw):

27,3 21,1 27,3

Adjustable min. heating load

(kW):

13,8 10,6 ---

Burner pressure at max.

capacity:

11 mbar

9 mbar

29 mbar

Burner pressure at min.

capacity:

2,8 mbar

2.3 mbar

---

Nominal gas consumption

max/min *:

2,89-1,46

2,46-1.23

0,85

Efficiency (%):

88 86,7 88

Pcs. of main burner nozzles:

16 16 16

Flue gas connection:

Ø

132 mm

Adjustment range of water

50 - 90

°

C

Electric power:

230 V, 50 Hz

Fuse (mA):

800; 100

Max. electric power

Max. 130 W

Protection:

IP 45

Shock prevention category: I.

Adjustment range of room

temperature controller:

5-30

°

C

Weight (kg):

22

(*): At 15 ºC and 1013 mbar

Table 1.

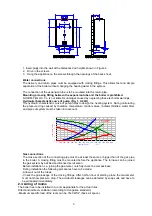

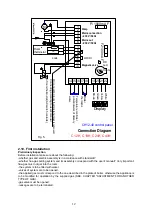

2. General instructions for installation

2.1. Placement of the appliance

-

Make sure that the wall is suitable for mounting the appliance on it.

-

Avoid mounting on less solid separation walls.

-

Do not mount the boiler above an appliance that could influence the perfect operation

of it. (E.g.: kitchen appliances generating greasy steam.)

Do not install the boiler in a room where the air is corrosive or dusty.

2.2 Mounting the appliance

Before setting to mount the boiler the whole heating system must be flushed as much as possible

in order to remove stains out of the tubes and radiators, which by getting into the appliance alter its

operation (especially sludge, metal parts, oil and grease). Before connecting the boiler to an "old", big

water-spaced system it is important to flush the circle, to remove the scale by solution of acid and to

install a filter into the returning pipe in front of the boiler.

With the help of a suitable designer a technical plan must be made about the heating system, the

gas supply, the flue-gas piping and the electric connections.