- 20 -

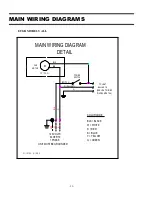

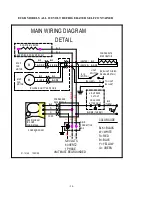

Case Does Not Operate

Check for disconnected power supply.

Check for tripped breaker or blown fuse.

Check that the thermostat is not “off”.

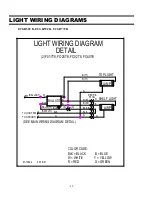

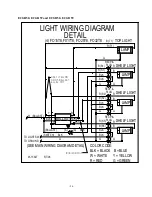

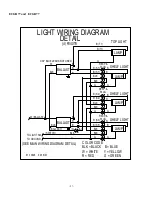

Lights Do Not Operate

Check that light switch is on.

Be sure light is properly seated in the sockets.

Check that light cord(s) are tight in the sockets.

Plug unused light sockets with socket cap provided with socket.

Case Temperature Too Warm

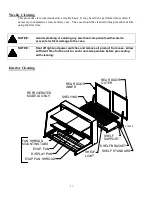

Check that the cold air inlet and outlet slots are not blocked.

Be sure that the rear doors are closed and tightly sealed.

Check for a blocked or dirty condenser coil filter or condenser coil fins.

Check cold airflow. Lack of adequate cold airflow could be a defective evaporator fan or

blocked evaporator coil. Check that paper or foreign material is not blocking evaporator.

If the evaporator coil is blocked due to excessive frost, turn the thermostat knob to the

“off” position for approximately one hour to defrost. Excessive frost will buildup if the

case is operated with the door open or ajar.

Check that the display pans are installed properly.

Glass Fogging

Check room ambient – Case is designed to operate in an environment not to exceed 75

°

F

and 55% relative humidity.

Check case temperature – Case is designed to operate between 38

°

F and 42

°

F.

Check that nothing is placed on the top of the case glass.

Summary of Contents for ECGR50

Page 29: ...29...