SECTION II

Inspection Electrically Operated

Breakers

The

stored

mechanism is charged by

fractional

AC/DC universal motor. Identifi-

cation, voltage ranges and

requirements

below. The stored

mechanism charges in

approximately one second.

CHARGING MOTORS FOR FP BREAKERS

STORED ENERGY MECHANISM

Rating

Part

F u s e ’

D.C.

162.007

15056 20 50

12.0

14976

6.5 25

5.0

14978

6.1 12

3.5

Maximum

use control power transformer

for higher voltage

‘Class 1330

element fuses

From wiring diagram supplied with equipment, or standard

diagram Part 7 of this book, locate motor

on

secondary contacts and connect required power source.

Motor will charge when power is applied and shutoff auto-

matically when

is

Breaker cannot be closed with the maintenance closing

handle unless stored energy mechanism is charged. 0” all

electrically operated FP breakers the stored energy mech-

anism will recharge immediately following a closing opera-

tion ready for instant

if needed.

Follow inspection procedure as outlined

Manually Operated Breakers.”

in “Inspection

In addition the following steps are recommended:

16. From wiring diagram locate

on secondary

contacts and connect proper control power supply and

controls for shunt close and shunt trip attachments.

Close and open breaker five times electrically and

check for proper operation.

17. Disconnect control power supply.

and

breaker manually. Do not leave breaker in the charged

and/or closed position while in storage.

18. Move shunt close solenoid

release closing springs without control power.

SECTION Ill Installation

Before installing breaker in cell, check following points

inside cell:

1.

contact support when supplied

make

sure all connections are tight and adjusted to proper

dimensions.

2. Ground connections should he tight.

3. Extension rails should be free to

in and

check rail stops for tightness.

4. Rail rollers should be free and well lubricated.

5. Main

stabs should be tight

free of dust

and dirt. Lubricate with contact grease.

6. Check condition of insulating

plate in roof of

case. Screws should be tight.

7. Remove control

fuses.

8. Place breaker

fully extended

rails. Make

four rollers

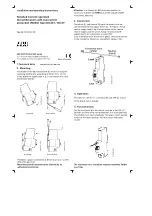

inside grooves (Outside

grooves fit into stationary rails inside cell). (Figure 7).

Figure 7

9. Draw-out mechanism on breaker should be in

position.

10. Push breaker inside the cell until racking-i” cranks

engage a positive stop. This is the OUT position.

11. Close and fasten the door. The metal mask provided

on outside of front box

freely back

it

in contact with the door. The door should

all the way with the breaker in the OUT position.

12. Push

interlock to left, insert

lever

1101-9251, (Figure 8) into the bottom hole of the

mechanism and, with

up-stroke, rack

breaker into the

TEST

position.

Remove

lever,

interlock plate should snap into position com-

pletely covering

holes.

13. Install control power fuses, energizing the circuit. The

motor will

the stored energy mechanism. The

closing and tripping control

become energized

in the TEST position.

14. Open

and make sure that grounding contact in

cell is in

with the breaker. Close door and

check breaker

for proper closing and

opening operation.

If breaker operates properly, rack breaker back to OUT

position and leave there until ready to be put into service.