Maintenance - 50h

70

4812274432.pdf

2017-07-10

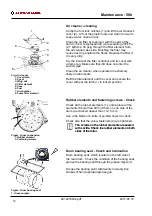

Air cleaner - cleaning

Fig. Air cleaner

1. Cover latch

2. Cover

3. Wing nut

4. Filter element

5. Case

6. Seal

7. Air chamber

8. Foam filter element

1

2

3

4

5

6

7

8

Unclip the four lock catches (1) and lift the air cleaner's

cover (2). Lift out the plastic foam and clean it in warm

soapy water, rinse and dry.

Clean the air filter by tapping it with the palm of the

hand or blow compressed air (not exceeding 207 kPa

(2,1 kgf/cm2, 30 psi)) through the filter element from

the air cleaner case side. Brushing the filter may

cause dust to penetrate the fibres. Replace the filter if

it is very dirty.

Dry the inside of the filter container and its cover with

a damp rag. Make sure that dirt does not enter the

suction pipe.

Clean the air cleaner when operated in extremely

dusty environments.

Refit the filter element and the cover and secure the

cover with put the latch (1) to locked position.

Rubber elements and fastening screws - Check

Figure. Drum suspension

1. Rubber element

2. Fastening screws

1

2

Check all the rubber elements (1), and replace all the

elements if more than 20% of them on one side of the

drum are cracked deeper than 10-15 mm.

Use a the blade of a knife or pointed object to check.

Check also that the screw fasteners (2) are tightened.

The screws on the rubber elements are sealed

with Loctite. Check the rubber elements on both

sides of the roller.

The screws on the rubber elements are sealed

with Loctite. Check the rubber elements on both

sides of the roller.

Drum bearing seat - Check and lubrication

Figure. Drum bearing seat

1. Grease nipple

1

Drum bearing seat, which located on the left side of

the rear drum. Check the condition of the bearing seat,

grease the bearing seat through the grease nipple (1).

Grease the bearing point with twenty to twenty-five

strokes of hand-operated grease gun.

1

Summary of Contents for Dynapac CC900G

Page 2: ......

Page 16: ...Safety when operating 8 4812274432 pdf 2017 07 10 ...

Page 20: ...Special instructions 12 4812274432 pdf 2017 07 10 ...

Page 22: ...Technical specifications Noise Vibrations Electrical 14 4812274432 pdf 2017 07 10 ...

Page 30: ...Machine description Decals 22 4812274432 pdf 2017 07 10 ...

Page 42: ...Operation 34 4812274432 pdf 2017 07 10 ...

Page 54: ...Operating instructions Summary 46 4812274432 pdf 2017 07 10 ...

Page 56: ...Operating instructions Summary 48 4812274432 pdf 2017 07 10 ...

Page 58: ...Preventive maintenance 50 4812274432 pdf 2017 07 10 ...

Page 62: ...Maintenance Lubricants and symbols 54 4812274432 pdf 2017 07 10 ...

Page 70: ...Maintenance Maintenance measures before use 62 4812274432 pdf 2017 07 10 ...

Page 80: ...Maintenance 100h 72 4812274432 pdf 2017 07 10 ...

Page 88: ...Maintenance 500h 80 4812274432 pdf 2017 07 10 ...

Page 96: ...Maintenance 1000h 88 4812274432 pdf 2017 07 10 ...