1st edition, 17-09-2020

7000.05070, 1st edition, 17-09-2020

7000.05070

Installation

13

4.1.2

Mounting the motor

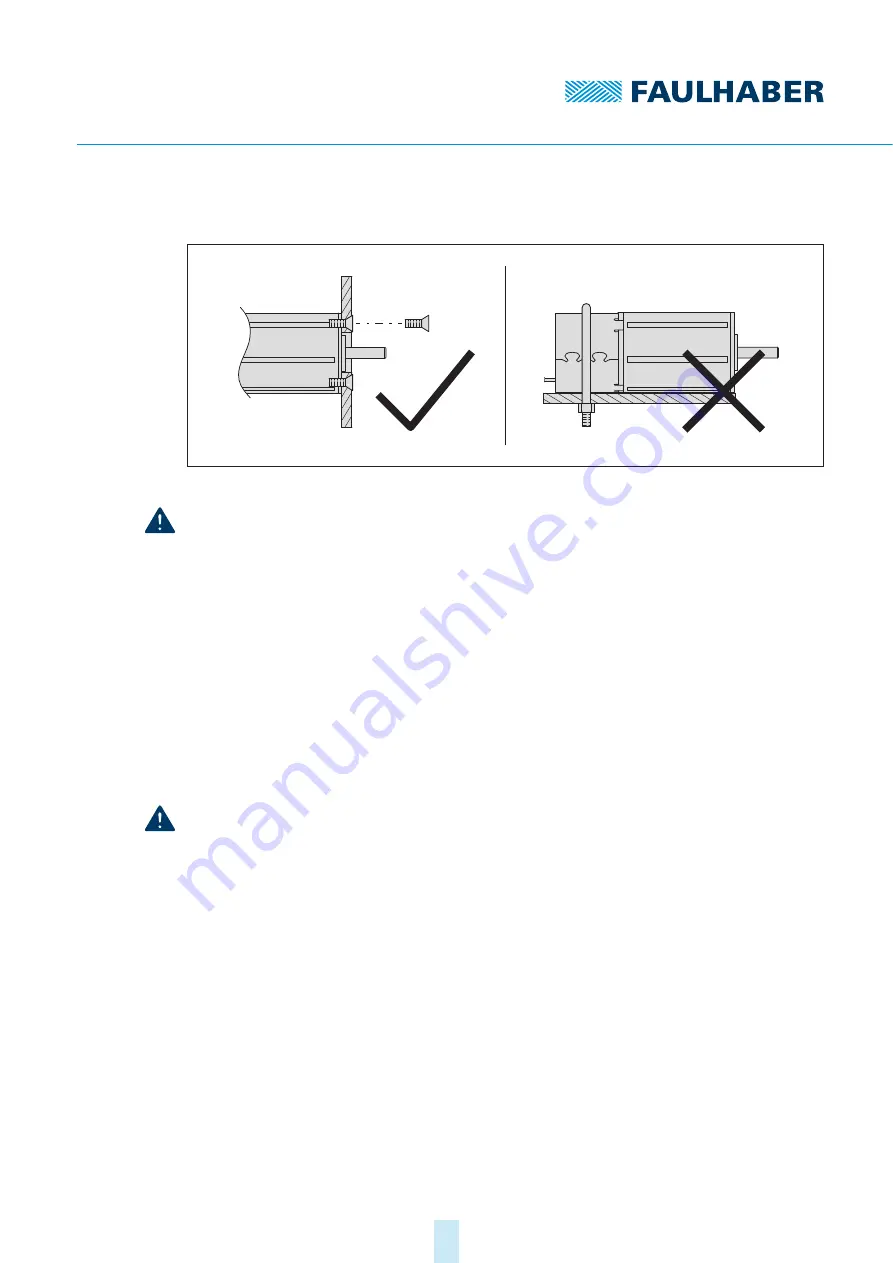

Fig. 5:

Mounting example – 22xxBX4 AEMTL series

NOTICE!

Excessive radial loads on the servomotor or excessively tightened fastening screws can

cause irreparable damage to the mounting flange.

Do not apply a radial force exceeding 30 N at the rear end of the motor.

Make sure that the screws are tightened to max. 50 Ncm.

Make sure that the screws are of sufficient strength.

1. Secure the front flange of the motor to a suitable surface using fastening screws.

2. Protect the fastening screws to prevent displacement due to the effect of heat.

3. If necessary, attach parts to the motor shaft.

4.1.3

Load of the connection cables

NOTICE!

Extreme static or dynamic loads on the ribbon cable can cause the cable to be damaged.

Make sure that the ribbon cable is not subjected to abrasion, crushing or excessively

tight bending radii during installation and operation.

With frequent bending, the bending radius must not be less than 10 mm. The possible

number of bending cycles increases as the bending radius increases.

Do not bend the cable at temperatures < –10 °C.

Comply with permissible loads.

Permissible loads of the ribbon cable:

Tensile load: <30 N

Continuous tensile load: <17 N

Bending radius with one-off installation: >1.2 mm