888-999-7715

www.FastListParts.com

11

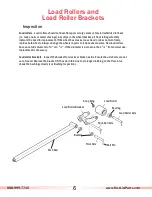

Installation - T Series

Standard height

- Insert the eccentric through the lifting link

and push rod. Secure it with its snap ring. Insert the push rod

axle through the bracket and push rod. Secure with its snap

rings. Slide the pivot axle through the frame and bracket.

Secure the axle in place with its snap rings.

Turn the jack upright and fully lower it. Adjust the push rod by

turning the eccentric with a large screwdriver through the

access hole on the side of the frame. By turning the eccentric

you effectively lengthen or shorten the push rod.

Test the adjustment by pumping the jack up and then lowering

it. If the forks hit bottom at the same time, then it is adjusted

correctly. If one fork hits bottom before the other, then further

adjustment is necessary.

Turn the eccentric about 1/8 to 1/4 of a turn and test the

adjustment again. Once the push rods are adjusted correctly,

turn the jack over onto its side and tighten the set screw down

to keep the eccentric from turning. (30 minutes)

Lowered height

- Thread the push rod onto the eye bolt and try

to match the other side if it is still assembled. If it isn't, adjust

the length after you have assembled the load roller bracket

onto the push rod.

Insert the push rod axle through the bracket and push rod.

Secure the axle in the bracket with the roll pin. Insert the pivot

axle through the frame and bracket. Secure the axle in the

bracket with the roll pin.

If you have not adjusted the push rod yet, place the lifting link

in a position that matches a fully lowered position. Spin the

push rod and bracket one way or the other until the pivot axle

hole on the bracket lines up with the frame. Then insert and

secure the pivot axle.

Test the adjustment by pumping the jack up and then lowering

it. If the forks hit bottom at the same time, then it is adjusted

correctly.

If one fork hits bottom before the other, then further adjustment

is necessary. You can either shorten the push rod on the fork

that hits first or lengthen the push rod on the fork that hits

second.

It is easier if you do the adjustment on the eye bolt end once

the load wheel bracket is attached to the frame. Remove one of

the snap rings on the pin that fastens the eye bolt to the lifting

link, and punch the pin out. Pull the eye bolt away from the

lifting link and turn it one way or the other to adjust as needed.

Assemble the eye bolt and the lifting link with the pin and its

snap rings. Turn the jack over and test the adjustment. Keep

adjusting until both forks hit bottom at the same time.

(25 minutes)

Installation - E Series

Standard height

- Thread the push rod onto the eye bolt. Try to

match the other side if it is still assembled. If it isn't, adjust the

length after you have assembled the load roller bracket onto

the push rod. Insert the push rod axle through the bracket and

push rod. Secure the axle with the snap rings. Insert the pivot

axle through the frame and bracket. Secure the axle in the

frame with the snap rings.

If you have not adjusted the push rod yet, place the lifting link

in a position that matches a fully lowered position. Spin the

push rod and bracket one way or the other until the pivot axle

hole on the bracket lines up with the frame. Then insert and

secure the pivot axle.

Test the adjustment by pumping the jack up and then lowering

it. If the forks hit bottom at the same time, then it is adjusted

correctly. Turn the jack over onto its side and tighten the nut on

the eye bolt up to the push rod to secure the adjustment during

any other repairs. If one fork hits bottom before the other, then

further adjustment is necessary. You can either shorten the

push rod on the fork that hits first or lengthen the push rod on

the fork that hits second. Keep adjusting until both forks hit

bottom at the same time. (25 minutes)

Lowered height

- Thread the push rod onto the eye bolt. Try to

match the other side if it is still assembled. If it isn't, adjust the

length after you have assembled the load roller bracket onto

the push rod. Insert the push rod axle through the bracket and

push rod. Secure the axle in the bracket with the roll pin. Insert

the pivot axle through the frame and bracket. Secure the axle in

the bracket with the roll pin.

If you have not adjusted the push rod yet, place the lifting link

in a position that matches a fully lowered position. Spin the

push rod and bracket one way or the other until the pivot axle

hole on the bracket lines up with the frame. Then insert and

secure the pivot axle.

Test the adjustment by pumping the jack up and then lowering

it. If the forks hit bottom at the same time, then it is adjusted

correctly. If one fork hits bottom before the other, then further

adjustment is necessary. You can either shorten the push rod

on the fork that hits first or lengthen the push rod on the fork

that hits second. Keep adjusting until both forks hit bottom at

the same time. (25 minutes)

Push Rods