11

Cutting blades

breaking

1. Blades are dull.

2. Blade bolts are loose.

3. Rebar is being dropped into

the cutter.

4. You are cutting “no grade”

steel

5. Bar is being cut on the top

corner of the cutting blade

1. Turn blades to a new

edge sooner.

2. Check blade bolts for

tightness more often.

3. Place rebar into the cutter

with greater care.

4. Only cut grade 40 or

grade 60 rebar.

5. Bar must rest on the

bottom of the cutter

opening.

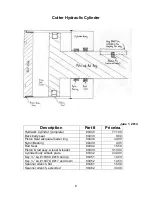

Oil is leaking

1. Hydraulic tubes and fittings

are loose or damaged.

2. Hydraulic cylinder body seals

or rod seal is leaking

1. Check fittings for

tightness. Replace

damaged fittings or tube.

2. Install new body and/or

rod seals in hydraulic

cylinder.

Cutting is slow

and lacks power

1. Oil level is low.

2. Oil is contaminated.

3. Hydraulic pump is worn.

1. Add oil to tank.

2. Drain and refill oil tank

with fresh ISO-46

hydraulic oil.

3. Replace hydraulic pump.