2. Disassembly

When a valve is first received in the shop, it should

be given a visual inspection to note its condition

when removed from service. The valve should

then be carefully dismantled. Proper facilities and

tools should be available. At each stage in the dis-

mantling process, visually inspect all parts of the

valve for evidence of wear and corrosion. If parts

are worn, replace them.

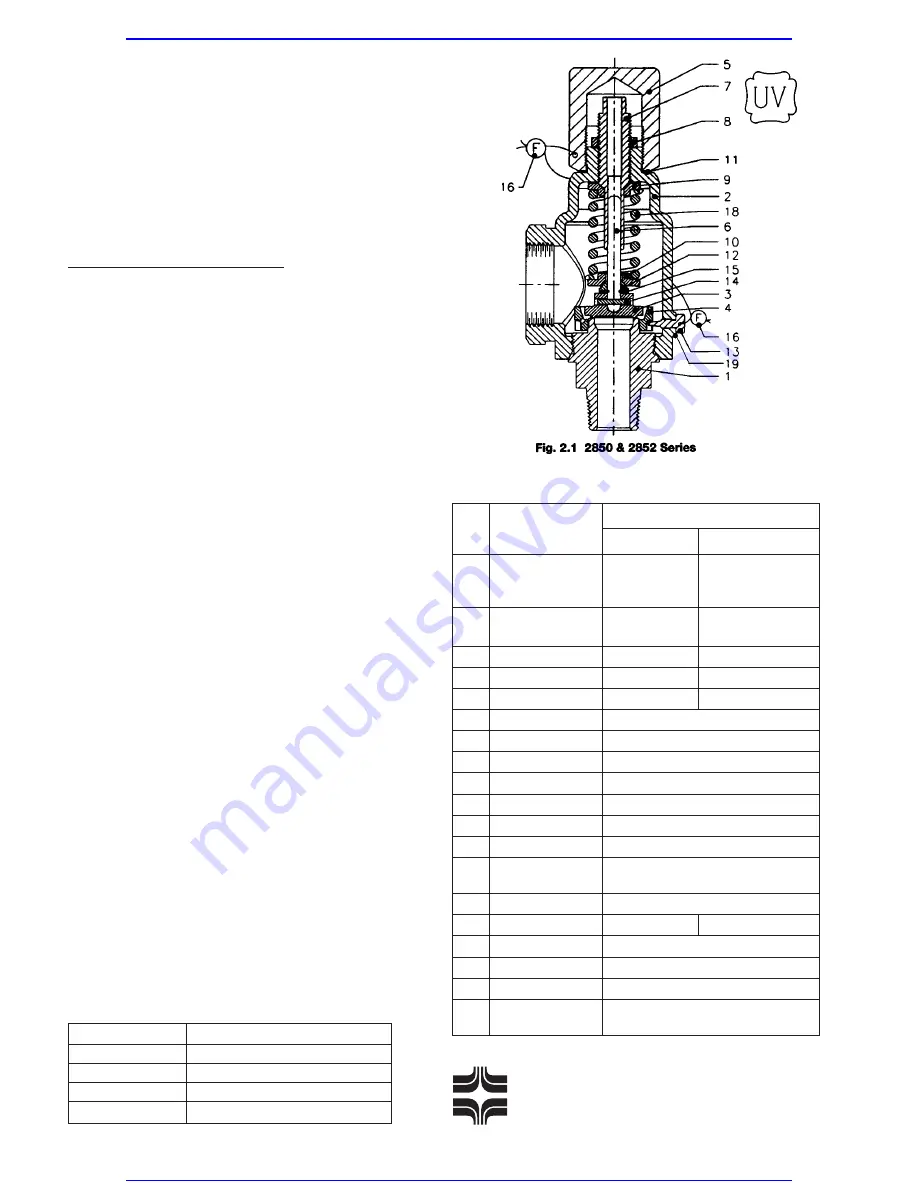

Series 2850 and 2852 (Fig. 2.1)

1. Mount valve vertically in a vise utilizing the flats

in the body.

2. Remove wire seal. Unscrew cap by turning

counterclockwise. Remove cap gasket. (For

open lever and packed lever cap construction,

refer to the section on Lifting Lever

Assemblies.)

3. Measure the distance from the top of the spring

adjusting screw to the top of the bonnet. Use

this measurement when reassembling the valve

to approximately duplicate the original set

pressure.

4. Loosen the jam nut.

5. Relieve the spring compression by turning the

spring adjusting screw counterclockwise.

6. Remove blowdown ring lock screw and gasket.

7. Thread a pipe into the outlet and turn the bon-

net counterclockwise. Lift the bonnet off to

expose internal subassembly.

8. Remove the upper spring button, spring and

lower spring button from the stem.

9. Remove the stem shoulder. Stem shoulder ring

may be a one-piece clip or split rings. Be care-

ful during disassembly; split rings may fall free.

Current valves do not use a stem shoulder and

split ring. The stem shoulder is an integral part

of the stem.

10. Lift the stem with the disc attached. If desired,

remove the grooved pin and lift the stem from

the disc.

11. Unscrew the blowdown ring from the body.

12. Clean all parts and threaded surfaces thor-

oughly. Replace all gaskets. Lap the body

seat and disc surfaces. (See the section on

Lapping for details.)

Bill of Materials

2

Farris Engineering

Division of Cur tiss-Wright Flow Control Corporation

Item Part Name

Material

2850 & 2852 2850/S4 & 2852/S4

SA-479 Type 316

SA-479 Type 316

1

Body

St. St. or SA-351

St. St. or SA-351

Gr. CF8M St. St.

Gr. CF8M St. St.

SA-216 Gr. WCB

SA-351 Gr. CF8M

2

Bonnet

Carbon Steel

St. St.

3

Disc

316 St. St.

316 St. St.

4

Blowdown Ring

316 St. St.

316 St. St.

5

Cap

Carbon Steel

316 St. St.

6

Stem

316 St. St.

7

Spring Adj. Screw

316 St. St.

8

Jam Nut

316 St. St.

9

Upper Spring Button

316 St. St.

10

Lower Spring Button

316 St. St.

11

Cap Gasket

316 St. St.

12

Stem Shoulder

316 St. St.

13

Blowdown Ring

316 St. St.

Lockscrew

14

Grooved Pin

316 St. St.

15

Stem Shoulder Ring

St. St.

316 St. St.

16

Wire Seal

St. St. Wire/Lead Seal

17

Nameplate

(not shown)

Stainless Steel

18

Spring

See Spring Table

19

Blowdown Ring

316 St. St.

L/S Gasket

Valve No.

Spring Material

2850

316 Stainless Steel

2852

Chrome Alloy, Rust Proofed

2850/S4

316 Stainless Steel

2852/S4

Chrome Alloy, Nickel Plated

Spring Table

Visit www.boighill.com to request a quote.

Visit www.boighill.com to request a quote.