12

Assembly - 1066 & 1076 Conventional Auger

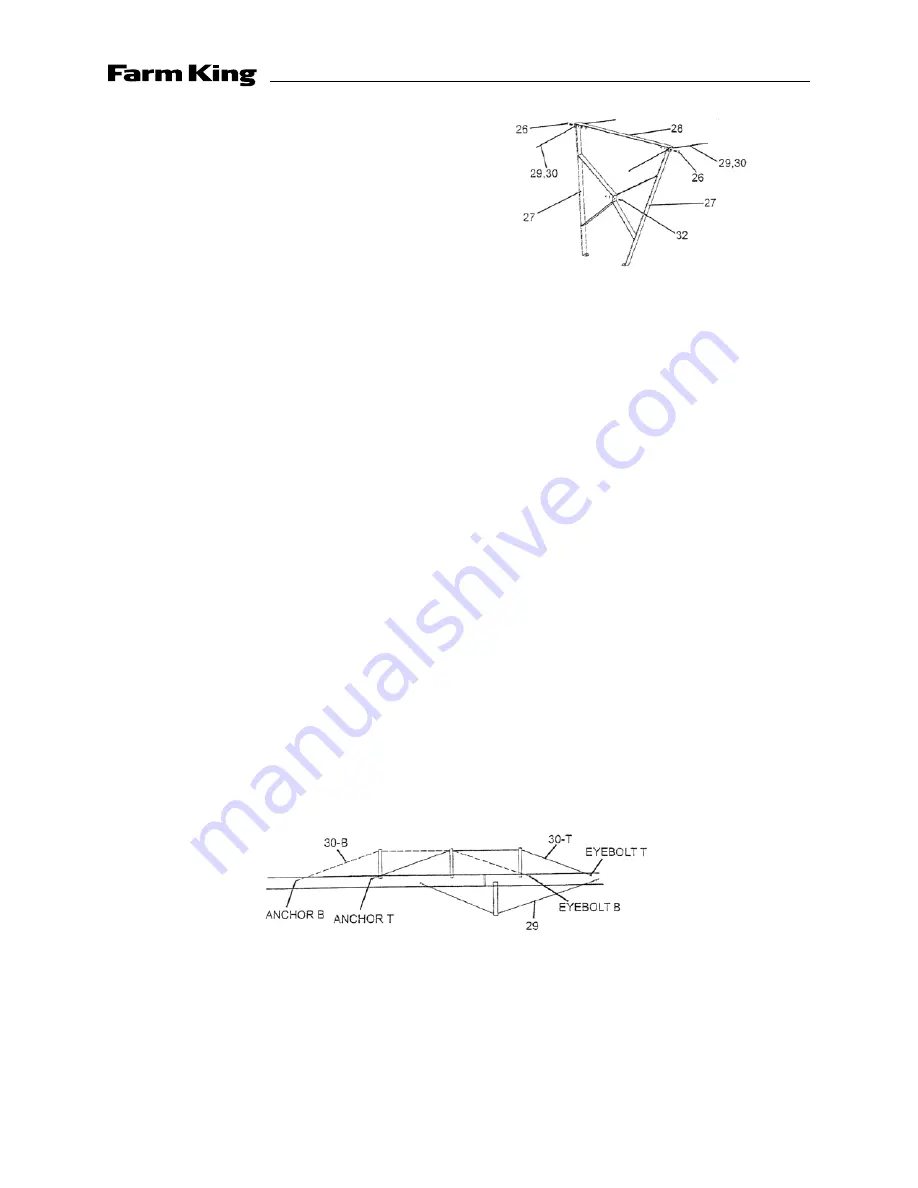

8. Assemble the truss risers as shown to

the right, using two supports (Ref. #27),

one 3/8" x 1" bolt, nut and lockwasher

combination (Ref. #32), one cross brace

(Ref. #28) and two 3/8" x 1-1/4" bolt, nut

and lockwasher combinations (Ref. #26)

per riser.

9. Mount the truss riser assemblies as instructed below

1066 Model

Mount the first truss riser assembly on the flange ring using the 3/8" x 1" bolt, nut and

lockwasher combinations (Ref. #32). Mount the second and third truss riser assemblies on the

truss mounts located on the top tube using 3/8" x 1" bolt, nut and lockwasher combinations

(Ref. #32). Install the 3/16" dia. truss cables (Ref. #30) using two cable clamps (Ref. #31) and

one cable thimble (Ref. #31) on each upper cable end. Be sure to run the cable through the

truss riser assemblies as shown. Tighten the cables with the eyebolts on the lower cable ends

to keep the auger straight.

Mount the undertruss riser assembly on the truss mount located on the lower tube using 3/8"

x 1" bolt, nut and lockwasher combinations (Ref. #32). Install the 1/4" dia. truss cables (Ref. #29)

using two cable clamps (Ref. #31) and one cable thimble (Ref. #31) on each upper cable end.

Be sure to run the cable through the truss riser assembly as shown. Tighten the cables with

the eyebolts on the lower cable ends to keep the auger straight. NOTE: Do not over-tighten the

undertruss. Over tightening the undertruss will cause the auger to bow down when the auger

is raised.

1076 Model

Mount the three truss riser assemblies on the truss mounts located on the top tube using

3/8" x 1" bolt, nut and lockwasher combinations (Ref. #32). Install the top pair (T) of 1/4" dia.

truss cables (Ref. #30) using two cable clamps (Ref. #31) and one cable thimble (Ref. #31) on

the upper cable ends. Install the bottom pair (B) of 1/4" dia. truss cables (Ref. #30) using two

cable clamps (Ref. #31) and one cable thimble (Ref. #31) on the upper cable ends. Both pairs

of cables go over the center riser. Be sure to run the cable through the truss riser assembly as

shown. Tighten the cables with the eyebolts on the lower cable ends. Adjust both top truss "T"

and bottom truss "B" to hold the auger straight. This process is trial and error, and experience

with trusses is helpful.

Mount the undertruss riser assembly on the truss mount located on the lower tube using 3/8"

x 1" bolt, nut and lockwasher combinations (Ref. #32). Install the 1/4" dia. truss cables (Ref. #29)

using two cable clamps (Ref. #31) and one cable thimble (Ref. #31) on the upper cable ends.

Be sure to run the cable through the truss riser assembly as shown. Tighten the cables with

the eyebolts on the lower cable ends to keep the auger straight. NOTE: Do not over-tighten the

undertruss. Over tightening the undertruss will cause the auger to bow down when the auger

is raised.