1

SECTION 1

DESCRIPTION

The Rheometer Calibration Fixture is designed for calibration verification and calibration

adjustment of the torsion spring in either the Model 280 or the Model 286 Rheometers. This

instruction describes checking and adjusting the strength of the torsion spring such that a known

torque will produce a known deflection, (dial reading). In this calibration known weights will be

used to produce a known amount of angular rotation of the bob shaft, or dial reading. The

Newton-cm of torque/degree of dial deflection is known as the K

1

factor. The K

1

(spring factor) is

adjusted by adjusting the active length of the spring.

The Calibration Fixture may be used for:

Calibration of a replacement spring when it is being installed.

Verification of the calibration of the spring already in the instrument.

Re-calibration of the spring already in the instrument.

Check the following parts of the Rheometer for runout or damage. If any of these parts are bent

or otherwise damaged, repairs must be made before a successful calibration can be performed.

Check the following:

Bob Shaft and Bob for runout -- Straighten or replace.

Maximum total runout allowed is 0.005 in. (0.127 mm)

Sleeve for runout -- Straighten or replace.

Maximum total runout allowed is 0.005 in. (0.127 mm)

Deformed or damaged spring -- Replace.

Mis-aligned dial "0" -- Readjust zero, (Refer to Sections 3-F7 or 4-F9)

Torsion Shaft bearings defective --Replace

Summary of Contents for 280

Page 5: ...2 ...

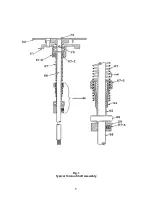

Page 8: ...5 Fig 1 Typical Torsion Shaft Assembly ...

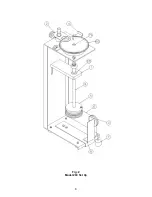

Page 9: ...6 Fig 2 Model 280 Set Up ...

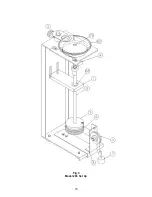

Page 13: ...10 Fig 3 Model 286 Set Up ...