VISCOSITY (IMPORTANT) —

The proper grade for R & O and

EP lubricants is found in

. For cold climate conditions refer

to

and the “Synthetic Lubricant” paragraphs. Select

a lubricant which has a pour point at least 10

°

F (5.5

°

C) below the

expected minimum ambient starting temperature. Usable

temperature ranges can sometimes be widened if specific

application conditions are known.

If a gear drive operates in a typical indoor environment where

the ambient temperature is within 70

°

F to 125

°

F (21

°

C to

52

°

C), the oil viscosity should be increased one AGMA grade

above that shown for the 50

°

F to 125

°

F(10

°

C to 52

°

C) range.

That is, an AGMA Number 6 or 7 should be substituted for a 5

or 6 respectively, under this ambient condition.

OIL PUMPS —

When selecting a lubricant for a gear drive

equipped with an oil pump, cold temperature oil viscosity is

important. Lubricant viscosity at start-up generally should not

exceed 1725 cSt (8,000 SSU). When exceeding this viscosity,

pump cavitation is possible, preventing oil circulation. A sump

heater may be required or it may be possible to use a lower

viscosity oil to minimize pump cavitation, consult the Factory.

Petroleum Based Lubricants

Industrial type

petroleum based rust and oxidation inhibited (R & O ) gear

lubricants are the most common and readily available general

purpose gear lubricants.

EXTREME PRESSURE (EP) LUBRICANTS

—

For

highly loaded gear drives or drives loaded in excess of original

estimates, industrial type petroleum extreme pressure lubricants

are preferred. The EP lubricants currently recommended are of

the sulphur-phosphorus type.

WARNING:

EP LUBRICANTS IN FOOD PROCESSING INDUSTRY

— EP lubricants may contain toxic substances and should not be

used in the food processing industry without the lubricant

manufacturers’ approval.

Lubricants which meet USDA “H1”

classification are suitable for food processing applications.

CAUTION:

EP LUBRICANTS & INTERNAL BACKSTOPS — Do

not use EP lubricants or lubricants with anti-wear additives or

lubricant formulations including sulfur, phosphorus, chlorine,

lead derivatives, graphite or molybdenum disulfides in units

equipped with internal cartridge type backstops. Some lubricants

may contain anti-wear additives. Lubricants in

do contain several of these additives.

Synthetic Lubricants

Synthetic lubricants of the polyalphaolefin type are

recommended for cold climate operation, high temperature

applications, extended temperature range (all season) operation

and/or extended lubricant change intervals. The proper viscosity

grade of synthetic lubricant is given in

WARNING

:

SYNTHETIC LUBRICANTS IN FOOD PROCESSING

INDUSTRY — Synthetic lubricants may contain toxic substances

and should not be used in the food processing industry without

the lubricant manufacturers’ approval. Lubricants which meet

USDA “H1” classification are suitable for food processing

applications.

CAUTION

:

SYNTHETIC LUBRICANTS & INTERNAL BACKSTOPS

— Synthetic lubricants may be used in gear drives with internal

backstops operating only in cold temperatures -30

°

to +50

°

F

(-34

°

to +10

°

C). Mobil SHC 624 and SHC 626 provide proper

backstop action under these conditions. Other synthetic

lubricants may also be acceptable. DO NOT use synthetic

lubricants in units with backstops operating in ambient

temperatures above 50

°

F (10

°

C).

Oil Levels

Prior to filling gear drives, remove the inspection cover and flood

the oil troughs with a generous flow of oil to the bearings. Fill the

drive with oil to the level indicated on the oil dipstick. Approximate

oil capacities are given on the drive nameplate.

Lubricant Changes

OIL ANALYSIS REPORT—

Checking oil condition at regular

intervals is recommended. In the absence of more specific limits,

the guidelines listed below may be used to indicate when to

change oil:

1. Water content is greater than 0.05% (500 ppm).

2. Iron content exceeds 150 ppm.

3. Silicon (dust/dirt) exceeds 25 ppm.

4. Viscosity changes more than 15%.

PETROLEUM LUBRICANTS —

For normal operating

conditions, change gear oils every 6 months or 2500 operating

hours, whichever occurs first. If the drive is operated in an area

where temperatures vary with the seasons, change the oil

viscosity grade to suit the temperature, refer to

Lubricant suppliers can test oil from the drive periodically and

recommend economical change schedules.

SYNTHETIC LUBRICANTS —

Synthetic lube change intervals

can be extended to 8000-10,000 hours depending upon

operating temperatures and lubricant contamination. Laboratory

analysis is recommended for optimum lubricant life and gear

drive performance. Change lube with change in ambient

temperature, if required. Refer to

The Falk Corporation, a Sundstrand Company, P.O. Box 492, Zip 53201-0492

148-050

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131

April 1999

Fax: 414-937-4359 e-mail: [email protected] web: www.falkcorp.com

Supersedes 4-89

Installation & Maintenance Instructions

•

Enclosed Gear Drives

(Page 4 of 8) Sizes 1080–1195 & 2050–2235

•

Types GHB, Y, YB & YBX

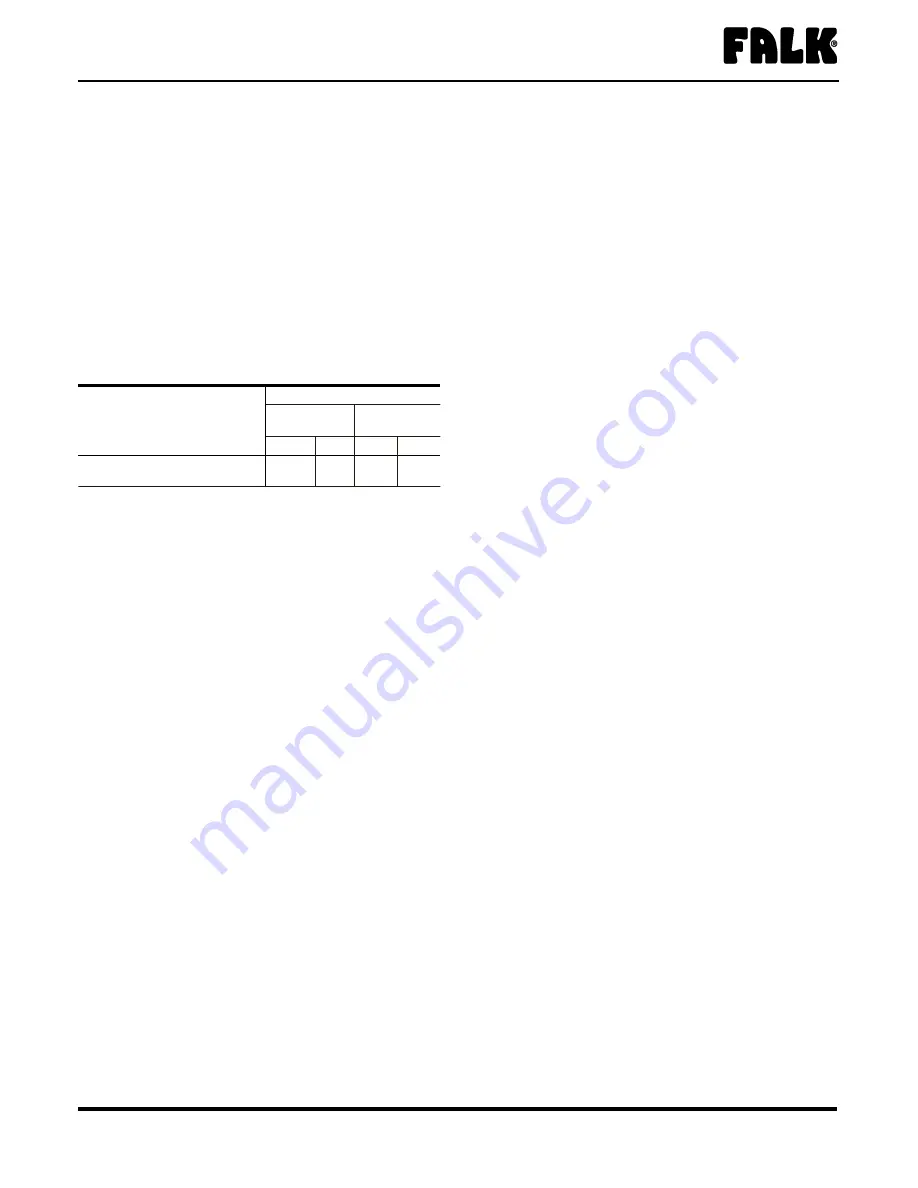

TABLE 2 — Viscosity Grade Recommendations

for R & O or EP Lubricants

Output RPM

Normal Climates

15

°

to 60

°

F

(-9

°

to +16

°

C)

50

°

to 125

°

F

(10

°

to 52

°

C)

ISO-VG AGMA ISO-VG AGMA

Output RPM Below 80

150 4 320 6

Output RPM 80 & Above

150 4 220 5