FALK FLUID COUPLINGS —

Refer to the installation manual

furnished with the fluid coupling for installation, alignment and

startup instructions.

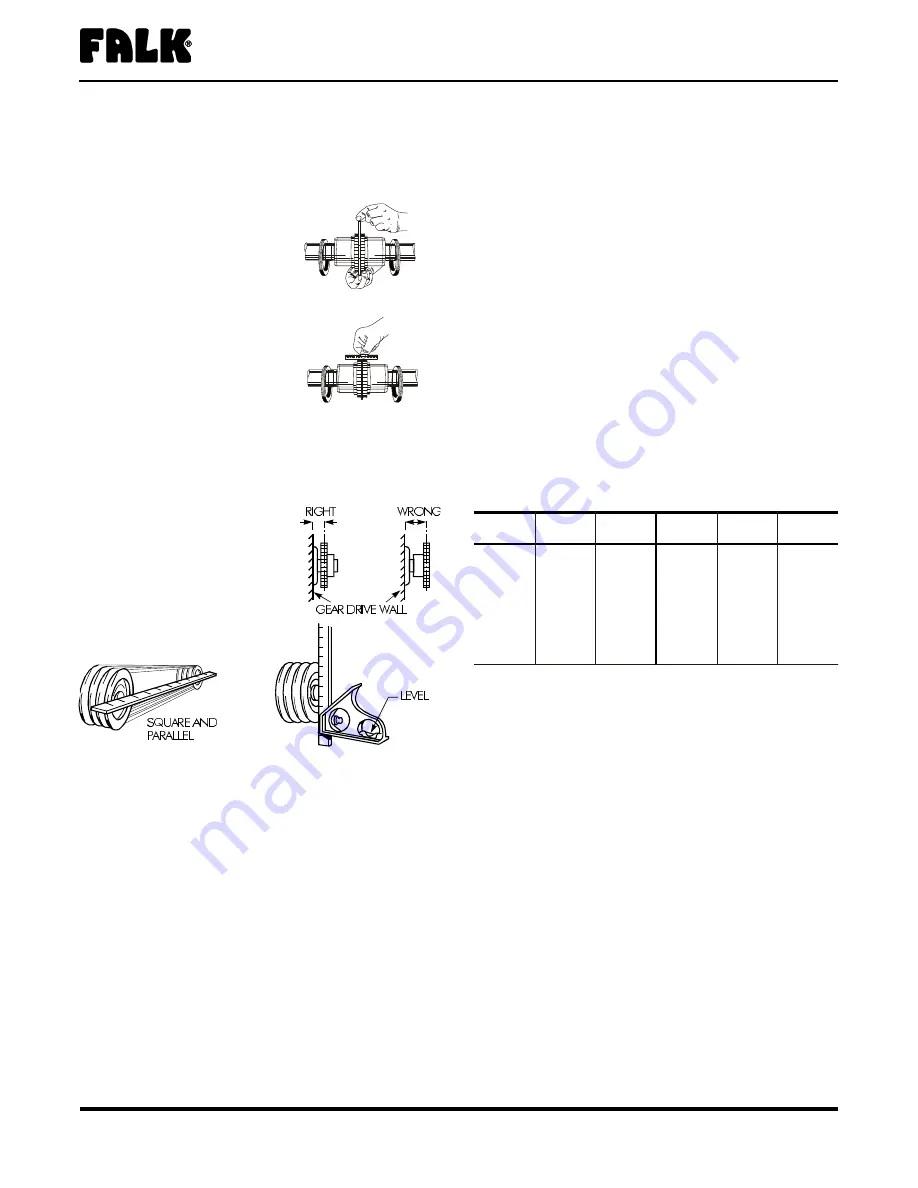

GAP AND ANGULAR ALIGNMENT —

If possible, after

mounting coupling hubs, position the driving and driven equipment

so that the distance between shaft ends

is equal to the coupling gap. Align the

shafts by placing a spacer block, equal

in thickness to required gap, between

hub faces, as shown above, and also at

90

°

intervals around the hub. Check

with feelers.

OFFSET ALIGNMENT —

Align

driving and driven shafts so that a

straight edge will rest squarely on both

couplings hubs as shown to the right

and also at 90

°

intervals. Tighten

foundation bolts of the connected

equipment and recheck alignment

and gap.

SPROCKETS, PULLEYS OR SHEAVES —

Mount power

take-offs as close to the gear drive housing as possible to

avoid undue bearing load and shaft deflection.

Align the output shaft of the gear drive square and parallel with

the driven shaft by placing a

straightedge across the face of the

sprockets or sheaves as illustrated.

Check horizontal shaft alignment

by placing one leg of a square

against the face of the sheave or

sprocket with the spirit level on

the horizontal leg of the square.

DO NOT over tighten belts or chains. Adjust chains to

manufacturers’ specifications. Adjust belts as follows:

The ideal tension is the lowest tension at which the belt will not

slip under peak load conditions. Check the belt tension

frequently during the first 24 to 48 hours of run-in operation.

Over tightening belts shortens belt and bearing life. Keep belts

free from foreign material which may cause slippage. Inspect

the V–belt periodically; tighten the belts if they are slipping.

OUTBOARD BEARING —

Mount the outboard bearing and

gear drive on a common foundation so that they will shift as an

assembly if settling should occur. Bring the outboard bearing to the

correct horizontal position with broad flat shims under the mounting

pad. Align accurately so that the load is equally divided between

the two drive bearings and the outboard bearing. Mount a stop bar

against the pillow block foot on the load side when large horizontal

load components are exerted on the pillow block.

PINION MOUNTING —

Mount pinion as close to the unit as

possible to avoid undue bearing load and shaft deflection. Refer

to the Factory for pinion alignment instructions.

BACKSTOPS —

To prevent damage to backstops due to

incorrect motor shaft rotation at start up, couplings are NOT

assembled when gear drives are furnished with backstops. After

completing the electrical connection, check motor and gear

drive shaft rotations. Then complete alignment and assembly

of coupling.

Fastener Tightening Torques

Use the tightening torque values specified in

for

fastening Falk gear drives, motors, keeper plates and accessories to

their mounting surfaces with non-lubricated fasteners. DO NOT use

these values for “torque locking” fasteners or for fastening

components with aluminum feet or with soft gaskets or vibration

dampers on the mounting surface. If the tightening torque exceeds

the capacity of the torque wrench, use a torque multiplier. Use

Grade 5

fasteners for diameters through 1.50", for larger

diameter

fasteners,

use

ASTM A-354 Grade BC.

Water Cooling

WATER COOLED HEAT EXCHANGERS

—

Install a shut-off or

control valve in the water line to the heat exchanger to regulate

the water flow through the exchanger. Also install a water flow

gauge between the control valve and the exchanger to

determine actual flow rate. Discharge water to an OPEN DRAIN

to prevent back pressure.

Lubrication Recommendations

Carefully follow lubrication instructions on the gear drive

nameplate, warning tags and installation manuals furnished with

the gear drive.

Lubricants listed in this manual are typical ONLY and should not

be construed as exclusive recommendations. Industrial type

petroleum based rust and oxidation inhibited (R & O) gear

lubricants or industrial type sulfur-phosphorus extreme pressure

(EP) gear lubricants are the recommended lubricants for

ambient temperatures of 15

°

F to 125

°

F(-9

°

C to +52

°

C).

For drives operating outside the above temperature range refer

to

“Synthetic Lubricants” paragraphs, Page 4.

lubricants can also be used in normal climates.

The Falk Corporation, a Sundstrand Company, P.O. Box 492, Zip 53201-0492

148-050

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone : 414-342-3131 April 1999

Fax: 414-937-4359 e-mail: [email protected] web: www.falkcorp.com

Supersedes 4-89

Enclosed Gear Drives

•

Installation & Maintenance Instructions

Types GHB, Y, YB & YBX

•

Sizes 1080–1195 & 2050–2235 (Page 3 of 8)

TABLE 1 —

Tightening Torques – lb-in

DO NOT LUBRICATE FASTENERS

Thread

Dia-UNC

Metal

to Metal

Metal to

Concrete

Thread

Dia-UNC

Metal

to Metal

Metal to

Concrete

.250-20

90 70

1.250-7

12600 10000

.3125-18

185 145

1.375-6

16500 13000

.375-16

330 255

1.500-6

22100 17500

.500-13

825 640

1.750-5

23700 18700

.625-11

1640 1280

2.000-4.5

37000 29000

.750-10

2940 2290

2.250-4.5

52000 41000

.875-9

4560 3750

2.500-4

72000 56000

1.000-8

6800 5600

2.750-4

98000 77000

1.125-7

8900 7000

3.000-4

125000 99000

STEELFLEX ILLUSTRATED

STEELFLEX ILLUSTRATED