Pneumatic Connections

Clean all pipelines to remove dirt and scale before installa

tion.

Apply a minimum amount of pipe compound to the male

threads of the air line only.

Do not use teflon tape as a

sealant.

Start with the third thread back and work away

from the end of the fitting to avoid contaminating the

transducer.

The inlet and outlet ports are labeled on the ends of the

transducer. Tighten all connections securely. Avoid

undersized fittings that will limit the flow through the

transducer. For more information, see Figure 2.

NOTE: Instrument quality air, per ISAStandards S7.3

1981, is required. Use a filter to remove dirt

and liquid in the air line ahead of the trans

ducer. If an air line lubricator is used, it MUST

be located downstream to avoid interference

with transducer performance.

The user is responsible for ensuring that the

environment in which the unit is installed and

the operating gas are compatible with the

materials in the transducer.

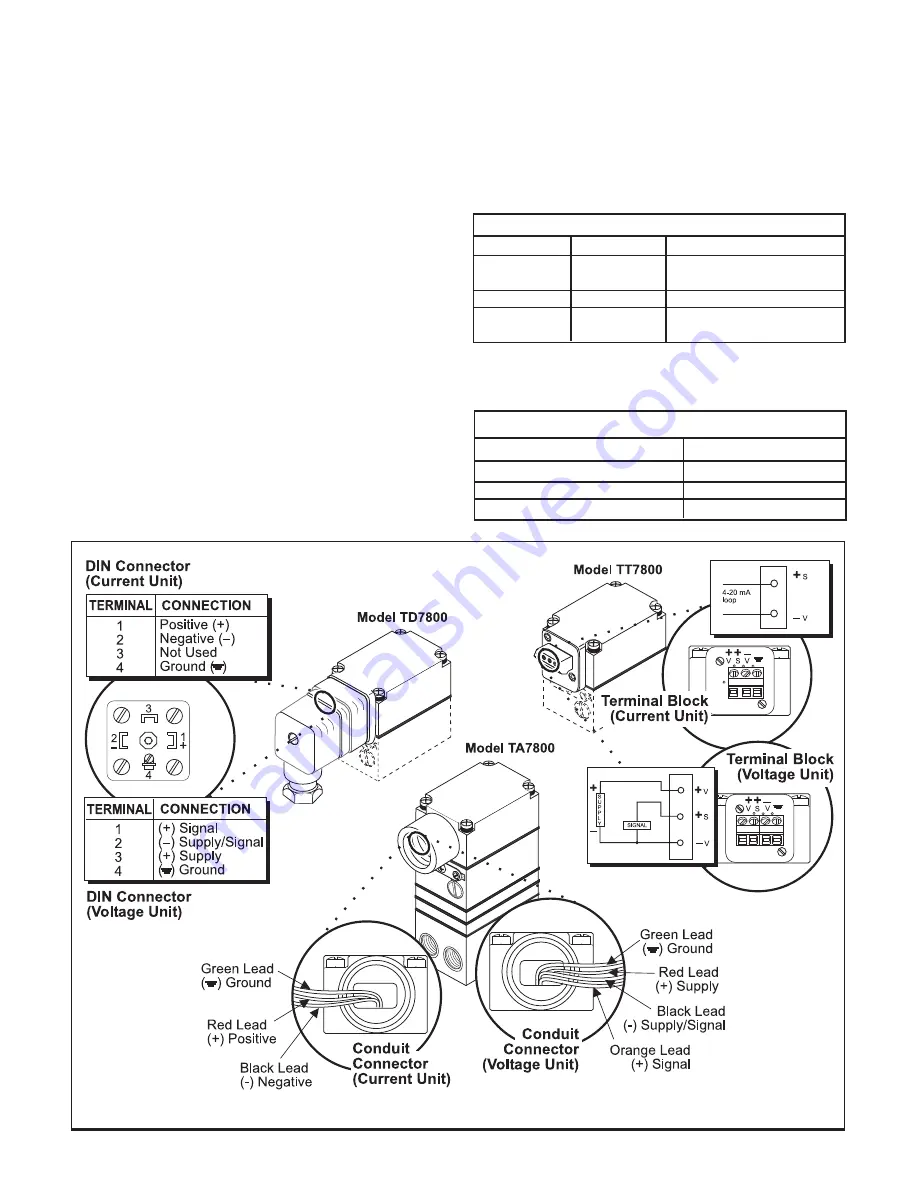

Electrical Connections

Make connections to the Terminal Block, Conduit Connec

tor or the DIN Connector as shown in Figure 9.

Wiring in Hazardous Areas

Wiring in hazardous areas should comply with the codes

in Table 1 and with any local codes that apply.

Table 1.

Hazardous Location Wiring Practices

Country

Agency

Code

U.S.

FM

ANSI/ISA RP 12.6

ANSI/NFPA 70

Canada

CSA

CED Part 1

Europe

ATEX

EN 50 039, EN 60079-14,

IEC 60079-14

Intrinsically Safe Connections

For more information, see the latest revisions of the draw

ings listed in Table 2.

Table 2.

Intrinsically Safe Connections

Underwriting Group

Drawing Number

FM (Factory Mutual)

EC-18970

CSA (Canadian Standards)

EC-18971

ATEX

EC-18972

Figure 9.

Electrical Connections

6