19

6.6 FINAL CHECKS

- Re-light and test for gas soundness

- Set the C.H. and D.H.W. temperature selectors to the required settings.

- Ensure that the time clock and/or room stat (if fitted) are set to the required setting (s).

6.7 USER’S INSTRUCTIONS

Upon completion of testing the system, the installer should:

- Give the ‘users Instructions’ to the owner and emphasise their responsibilities under the “Gas Safety

(Installation and Use) Regulations 1998”

- Explain and demonstrate the lighting and shut down procedures.

- Advise the owner on the efficient use of the system, including the use and adjustment of all system con-

trols for both D.H.W. and C.H.

- Advise the user of the precautions necessary to prevent damage to the system, and to the building, in the

event of the system remaining inoperative during frost conditions.

- Explain the function of the boiler lock-out devices, and how to reset it. Emphasise that if cut - out persists,

the boiler should be turned off and the installer or service engineer consulted.

- Stress the importance of an annual service by a Corgi registered heating engineer.

To ensure continued efficient operation of the appliance, it is recommended that it is checked and serviced

as necessary at regular intervals. The frequency of servicing will depend upon the particular installation con-

ditions and usage but in general once a year should be adequate.

It is the law that any service work must be carried out by registered personnel (C.O.R.G.I.).

Before commencing any service operation, ISOLATE the mains electric supply, and TURN OFF the gas sup-

ply at the main service cock. Service the appliance by following the full procedure detailed below.

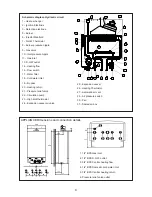

MINIMUM CLEARANCE REQUIRED FOR SERVICING AND REPLACEMENT OF PARTS

*

Distance at the side

The minimum distance necessary for carrying out maintenance operations, is 5 mm

*

Distance at the top

The minimum distance necessary for carrying out maintenance operations, is 200mm

*

Distance at the bottom

The minimum distance necessary for carrying out maintenance operations, is 250 mm.

*

Distance at the front

The minimum distance necessary for access during maintenance opera-

tions, is 250mm, although this distance may be reduced to 5 mm, as long

as a door is installed which can be removed when it comes to carrying out

maintenance work.

7.1 FRONT COVER REMOVAL

The cover is held in place by four spring clips and can be removed by

grasping it at the top and pulling forward sharply to release.

Further access can be gained by removing the control panel. (Four

screws), and the side panels. The side panels are retained on key hole

slots and need to be pushed up before being pulled forward.

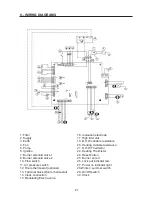

7.- ROUTINE SERVICING INSTRUCTIONS