5

-19

Maintenance

5

3

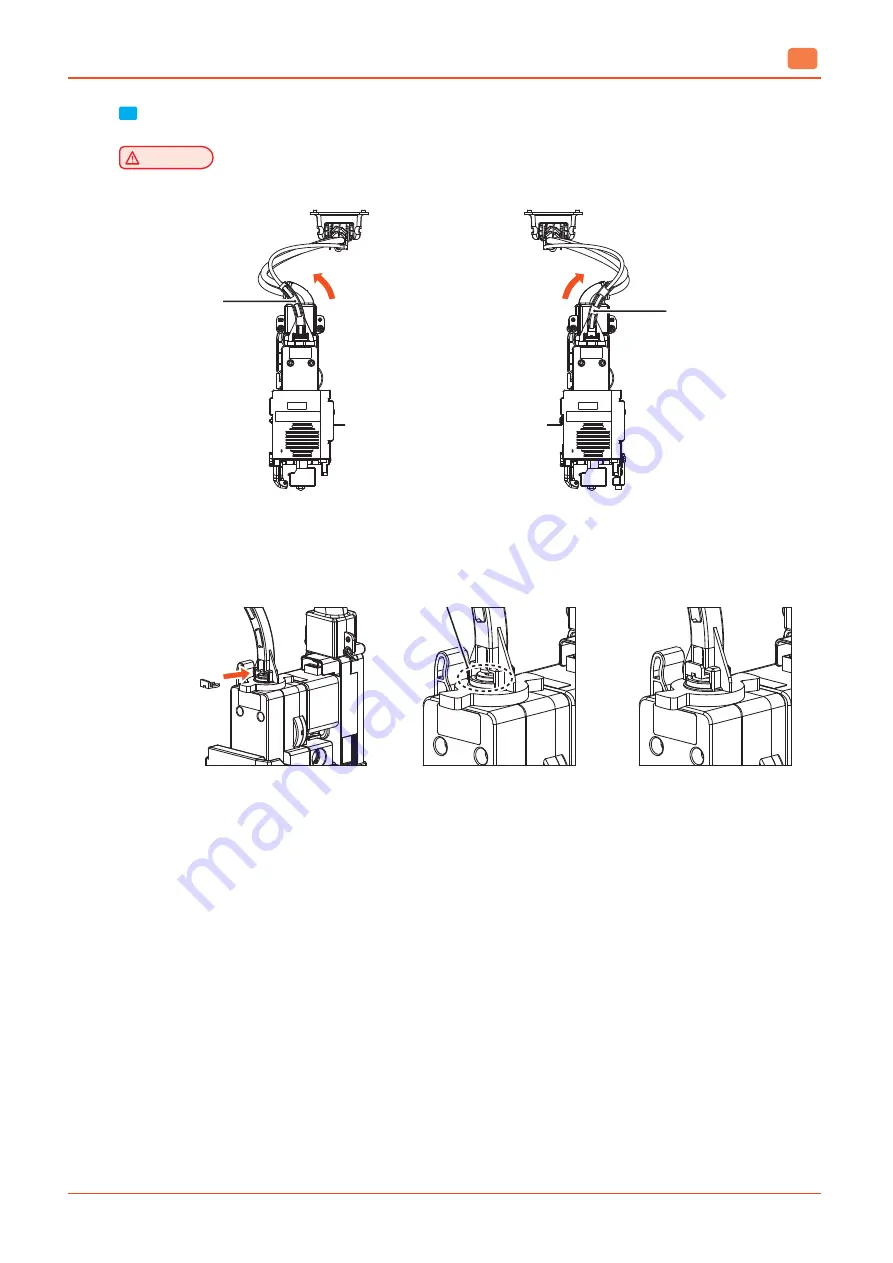

Assemble the snap rings after positioning the tube guides as shown in the figure below.

Caution

- If the snap ring comes off, the tube guide will not be fixed properly.

Tube Guide

Direction

(Nozzle #1)

Tube Guide

Direction

(Nozzle #1)

Tube Guide

Tube Guide

Nozzle #1

Nozzle #2

Snap ring assembly location

(Between the fitting and tube holder)

Assemble Snap-ring

Assembling completed

Summary of Contents for A530

Page 8: ......

Page 26: ......

Page 27: ...Preparation for Use 1 type A530 ...

Page 39: ...UI Menu Description 2 type A530 ...

Page 71: ...Print 3 type A530 ...

Page 76: ......

Page 77: ...Output checking 4 type A530 ...

Page 83: ...Maintenance 5 type A530 ...

Page 104: ...Maintenance 5 22 5 4 Close the top door ...

Page 111: ...5 29 Maintenance 5 4 Pull the nozzle core forward and lift it up to remove it ...

Page 116: ......

Page 117: ...Appendix 6 type A530 ...