FABER-COM srl - Via Romana 36/1 - 42028 Poviglio (RE) - Italy Tel. +39-0522-960428 Fax. +39-0522-969644 - www.fabercom.it

FABER-COM srl - Via Romana 36/1 - 42028 Poviglio (RE) - Italy Tel. +39-0522-960428 Fax. +39-0522-969644 - www.fabercom.it

Tecnico\Prodotti\Manipolatore\Jp\Documenti\SM#Manuale JP_v102_ie.cdr - 11/01/07

FABER-COM srl - Via Romana 36/1 - 42028 Poviglio (RE) - Italy Tel. +39-0522-960428 Fax. +39-0522-969644 - www.fabercom.it

COM

FABER -

JP

Page 3 / 8

PROGRAMMING MODE

To adjust JP working parameters, it is necessary to plug the PRG2 programming keyboard into the appropriate

connector. JP automatically recognise PRG2 connected and modify his working way to allow current calibration as

described below

Adjustable parameters:

The number of flashes of the programming keyboard LED indicates the programming step in which you are.

As PRG2 is connected You are in step no. 1.

By the pressure of "PREV" and "NEXT" push buttons you are able to navigate through the programming steps;

otherwise, by the pressure of "+" "-" push buttons you are able to increase and decrease the parameter

corresponding to the actual programming step.

At the end of the programming procedure, you have to push "PREV" and "NEXT" push buttons at the same time

to save in memory the new parameters value. If You do not give the SAVE command all modification will be loose

when JP is turned off.

Step 1: minimum current regulation (manoeuvres start up speed)

Step 2: maximum current regulation (manoeuvres max speed)

Step 3: rise timeramp regulation (manoeuvres acceleration speed)

Step 4: fall timeramp regulation (manoeuvres deceleration speed)

Step 5: bypass delay regulation (bypass delay time when all the manoeuvres stop)

Step 6: PWM frequency regulation (to reduce the solenoid valves histeresis)

For the programming steps from 1 to 4 it is necessary move the joystick to choose the manoeuvre which has to

be regulated. Actually, it is possible to set different values of min/max currents, rise/fall timeramp for each

movement (semi-axis).

During the programming mode, joystick continues to work normally to give you a real time feedback of the

changes done.

The only programming step which modifies joystick behaviour is step number 1, in which you regulate the

manoeuvres start up speeds. When the joystick is into this programming step, when you move the joystick the

manoeuvres will be turned on only at their start up speed; You have to adjust start speed until all manoeuvres will

start to move very slowly or are near to start.

When You move into programming step number 2, to tune maximum speed, You can verify the complete range of

the output currents from the minimum speed (regulated in the programming step number 2) to the maximum

speed (regulated here).

While the programming steps for 1 to 5 give you a real time feedback of the modifications, the programming step

number 6 (PWM frequency regulation) does not. If you cannot estimate the effects of the modifications, you have

to do a "blind" regulation.

So you have to know the right frequency value for the solenoid valve that you are using (usually indicated by

manufacturer). Find in the following table the index that correspond to the requested frequency.

When you are in programming step number 6, press for at least 2 seconds the "'-" button (in this way you reach

the 0 value of the frequency parameter). Then push the "+" button a number of times equal to the desired

frequency corresponding number.

NOTE: Remember to save parameters before turning off the joystick.

.

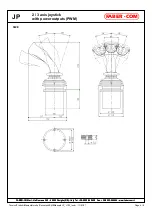

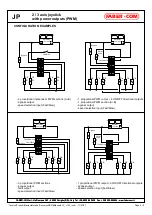

2 / 3 axis joystick

with power outputs (PWM)

50 Hz

60 Hz

70 Hz

85 Hz

100 Hz

125 Hz

150 Hz

200 Hz

250 Hz

300 Hz

0

1

2

3

4

5

6

7

8

9

PWM freq.

Index

Table of available frequences for PWM