5

E56-6001-000

02/16/2018

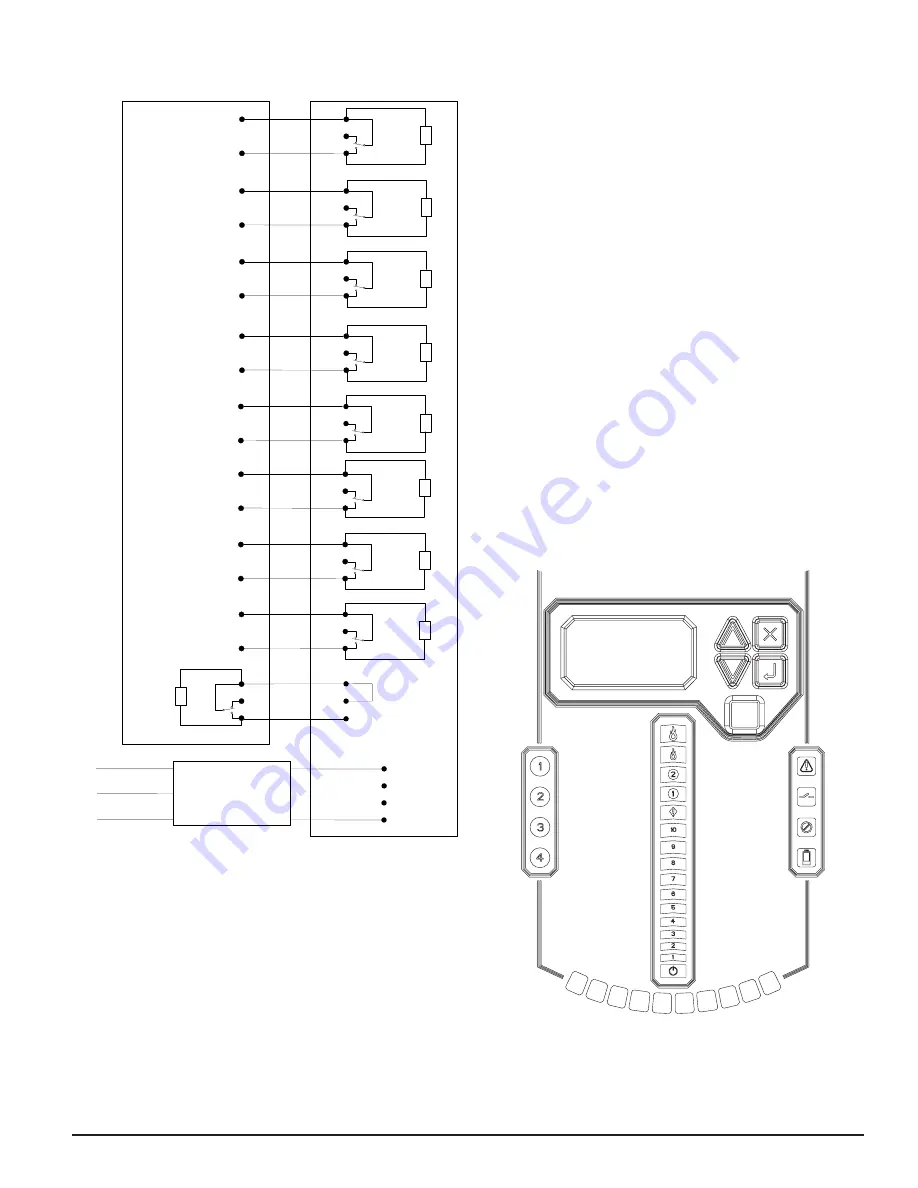

FIGURE 4. FACP WIRING DIAGRAM

N.C.

N.O.

C.

Fire Panel (FACP) typical connection

FAAST XT

for monitoring of device

Alarm

Short = Fire

Open = Fault

EOL

N.C.

N.O.

C.

Alarm

Short = Fire

Open = Fault

N.C.

N.O.

C.

Alarm

Short = Fire

Open = Fault

N.C.

N.O.

C.

Alarm

Short = Fire

Open = Fault

N.C.

N.O.

C.

Alarm

Short = Fire

Open = Fault

N.C.

N.O.

C.

Supervisory

Short = Isolate

Open = Fault

N.C.

N.O.

C.

(T

11

)

Short = Urgent Fault

Open = Fault

N.C.

N.O.

C.

(T

10

)

Short = Minor Fault

Open = Fault

FACP

Supervisory

Supervisory

EOL

EOL

EOL

EOL

EOL

EOL

EOL

External

Monitor

(T

13

)

N.C.

B.

B.

A.

N.O.

(Reset)

C.

47k

Ω

Red

Blue

EMI Line Filter

(included)

Red

Blue

Yellow (not connected)

24VDC

-

+

-

+

-

+

Panel’s

Remote

Reset

Alert

Re

la

y

C

ontacts

(T

5)

Action 1 Re

la

y

C

ontacts

(T6

)

Action 2 Re

la

y

C

ontacts

(T7

)

Fire 1 Re

la

y

C

ontacts

(T8

)

Fire 2 Re

la

y

C

ontacts

(T9

)

(T12

)

Ur

gent

Re

la

y

C

ontacts

Minor Re

la

y

C

ontacts

Isolate Re

la

y

C

ontacts

ASP136-01

SYSTEM POWERING

The following procedure describes how to initially power up the FAAST system.

1. Unplug the unit’s power connector to the unit before turning on the

power.

2. Turn on the power.

3. Check the voltage at the connector. Make sure it is within the required

voltage range.

4. If wiring is not connected to the external monitor terminal, install a 47k

Ω

resistor (provided with the unit) into the terminal block and fit it into

the T6 terminal. Remove spade connectors before installing in the wiring

terminal.

5. If the voltage is within the proper range, reconnect the power connector

to the unit.

6. Connect a computer, with PipeIQ installed, to the unit using either the

USB connection,or the Ethernet port located inside the wiring cabinet.

(See ‘Connecting to FAAST XT’ for detailed connection instructions.)

7. Use the PipeIQ software to set up the unit configuration required for the

particular application.

8. The PC may now be disconnected unless a permanent networked con-

nection is desired.

9. Verify the system fan starts up and air begins to flow out of the exhaust

port. The user interface will provide the device status.

10.

The device will establish an airflow baseline during the first five

minutes of operation after powering on, following the successful

download of a configuration to the device from PipeIQ, or after ini-

tiating Baseline Reset from Functions menu on the unit’s display.

During the initial baseline period the LCD will display Baseline message.

The calculated baseline is stored in the device’s non-volatile memory and

is used to monitor changes in the system’s airflow that may be caused

my dust build up, broken piping, clogged holes, etc. Therefore, it is im-

portant to verify that the system is setup and installed per the PipeIQ

design file and meets the requirement of the local codes and authorities.

The Baseline message is also displayed after power on reset, following

the initial baseline period. During the five minutes after power up the

device is monitoring the system to determine the current airflow baseline

of the system. Once the current airflow baseline is established, it is com-

pared to the initial baseline stored in non-volatile memory to determine

the overall health of the system.

USER INTERFACE

The user interface, shown in Figure 5, provides the following information:

• Detector status: Normal, Alarm, General Fault, Isolate Fault, Disable

Fault, Voltage Fault

• Alarm Level: Alert, Action 1, Action 2, Fire 1, Fire 2

• Particulate Level: 1 – 10 relative to Alert

• Flow level for each pipe inlet

• LCD for device test, service, and monitoring.

FIGURE 5. USER INTERFACE DISPLAY

ASP117-00

PARTICULATE LEVEL DISPLAY

The particulate level display, shown in Figure 6, consists of ten amber LEDs

that correspond to the current level of the particulate level detected. The LEDs

illuminate in order from Level 1 to Level 10, starting from the bottom of the

display and moving up as the particulate level increases. Each LED represents

a 10 percent increment in the particulate level relative to the Alert level.