E721

16

532014 - Rev.E

ENGLISH

7.4 MASTER / SLAVE CONFIGURATIONS

(1)

(2)

BUS

2 EASY

(1)

(2)

BUS

2 EASY

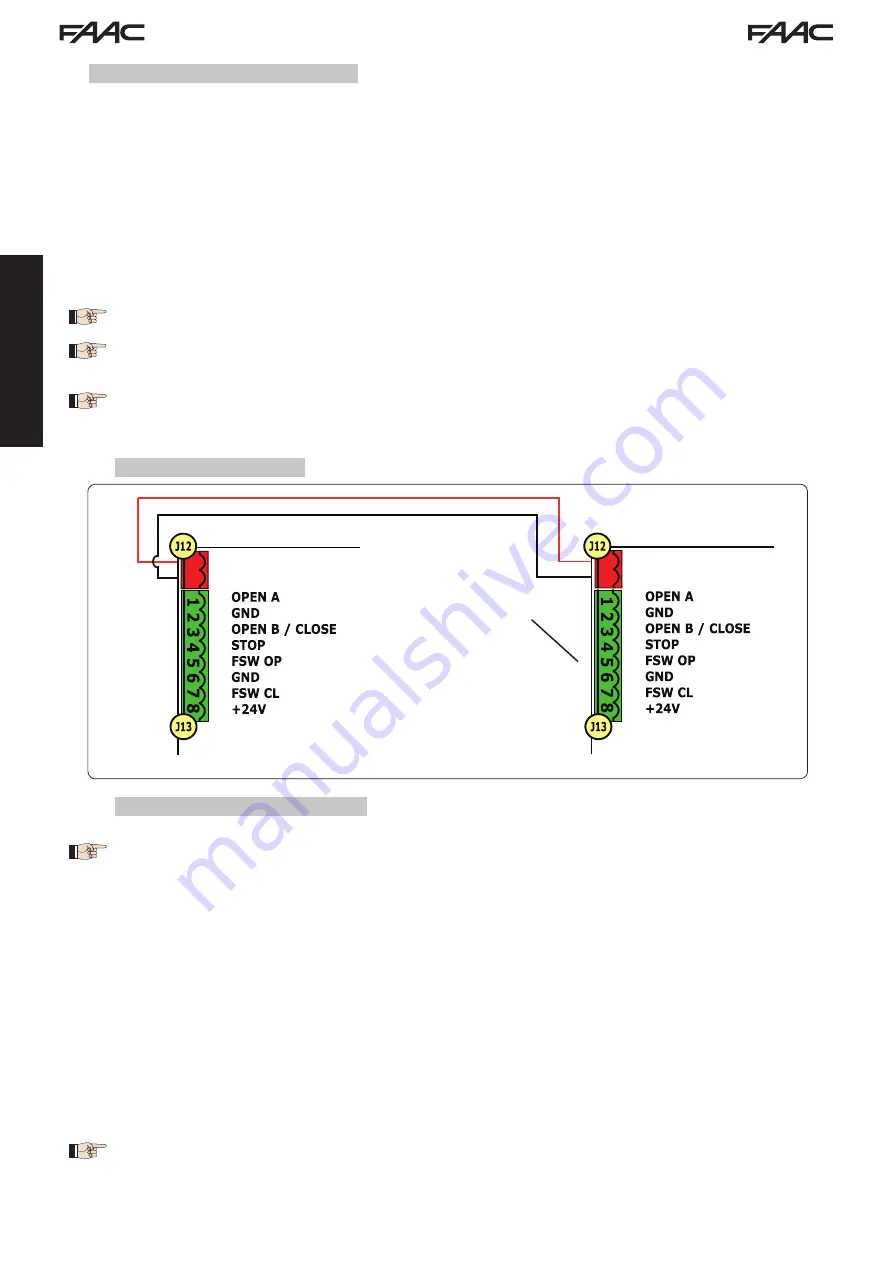

Should you need to build a system with opposing leaves that must be activated simultaneously

for opening and closing the gate, you must connect and configure two E721 devices in Master/Slave mode.

The MASTER equipment (parameter

C t

of the first programming level configured as

M A

) must have all the necessary

connections for correct operation of the system (photocells, safety switches, radio, opening pulses, flashing light)

while the SLAVE equipment (parameter

C t

of the first programming level configured as

S L

), must not be wired with

terminal board J13, as all the inputs present are completely ignored. The two devices will communicate with each

other through BUS-2EASY using two-pole

POLARISED

wiring on the J12 terminal board.

The MASTER device will completely control the SLAVE device through BUS-2EASY and will manage all the movements

and time of both leaves.

7.4.1 MASTER / SLAVE WIRING

7.4.2 MASTER/SLAVE SETUP PROCEDURE

Avoid any type of connection and wiring to terminal board J13 of the SLAVE unit.

The BUS connection between the two boards must be POLARISED following the sequence of the

poles of the J12 terminal board (POLE (1) - POLE (2)) - (see Fig. 19).

When a unit is configured as a SLAVE, this will force the values of some programming parameters

no longer displayed in the menu (

LO-PA-Pb-Ph-Op

). By placing the board in MASTER mode

again, the previously forced values are stored in the program.

E721 MASTER

E721 SLAVE

Do not connect

anything to this

terminal board

The SETUP request signalled by the flashing

S0

on the display can occur both on the MASTER unit

and on the SLAVE unit. In the latter case, the MASTER unit will display an error

91

. In any case, the

SETUP procedure can only be started from the MASTER unit.

To SETUP a MASTER/SLAVE system, follow the steps below:

1. Release both leaves, place them in the middle of travel and lock again (see procedure no.1 Par. 7.5 SETUP)

2. Keep pressed the SETUP button on the MASTER board until the MASTER gate begins to move.

3. At this point the MASTER gate will perform a complete SETUP procedure (see Par. 7.5 SETUP)

4. Once you have correctly completed the SETUP of the MASTER board, the complete SETUP procedure of the SLAVE

board begins (see Par. 7.5 SETUP).

5. Once this procedure has also been completed the MASTER checks the position of the SLAVE leaf and places it in

the same position (open or closed) as the MASTER leaf.

6. Procedure

completed.

In case of error or non-completion of the above-mentioned SETUP procedure, you must repeat it

completely starting from point no.1.

Fig. 19