Page F-8

FRONT SUSPENSION AND STEERING

Repair and Service Manual

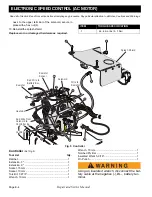

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings.

B

yoke onto the shaft. Do not tighten the upper cross

bolt and nut.

8. To install the steering column assembly align the lock-

ing tabs on the mounting bracket with the slots in the

frame and turn the assembly CW about 10° to align

the mounting holes. Make sure that the notch on the

steering column assembly mounting bracket is in the

same orientation as it was upon removal (up or down).

9. Install the four Torx screws (9) finger tight and then

tighten to the proper toque.

10. Apply a commercially available anti-seize compound

to the splines of the steering box pinion before install-

ing the yoke. Do not install the lower cross bolt (8) at

this time.

11. To align the steering wheel with the front wheels use

the following procedure:

a) Install the front wheels if they have been removed.

b) Remove the jack stands and lower the vehicle to

the ground.

c) Push vehicle backward about 5 feet and then for-

ward about 5 feet.

d) If the steering wheel is not oriented properly

remove the yoke from the steering box pinion and

turn the steering wheel to the correct orientation.

e) Install the yoke on the spline of the steering box

pinion.

6. Install the lower cross bolt (13) through the un-

threaded portion of the yoke, making sure that the lock

washer (14) is in place, into the threaded side.

7. Tighten the upper cross bolt (10) and nut (11), making

sure that the lock washer (12) is in place, then tighten

the lower cross bolt (13) to the proper torque.

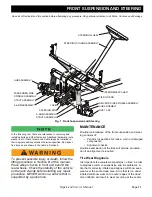

Rod End / Ball Joint

Tool List

Qty.

Socket, 16 mm.............................................................1

Ratchet ........................................................................ 1

Torque Wrench, ft. lbs.................................................. 1

Ball Joint Separator ..................................................... 1

Ball Peen Hammer ...................................................... 1

Inspect rod end or ball joint by grasping the end and

checking for vertical motion. If the rod moves up or down

this is an indication that the ball joint is worn and

requires replacement.

Raise and support the vehicle as described in the Safety

section of this manual. Remove the front wheels as

described in the Wheels and Tires section of this manual

1. Loosen the nut securing the tie rod end to the spindle

arm.

2. Using a ball joint separator as a lever, apply pressure

to the ball joint and tap the spindle arm sharply with

the ball peen hammer to release tie rod from spindle

arm.

3. Remove the nut and remove the tie rod end from the

spindle arm.

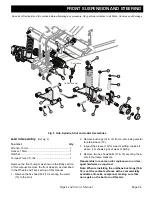

4. Measure the length of the threaded part of the rod

end to the jam nut or count the number of turns that it

takes to remove the rod end.

5. Install the new rod end the same number of turns that

were counted when removing the old rod end or to the

same measured length of the threaded part of the rod

end to the jam nut.

6. Install the rod end into the spindle.

7. Tighten the jam nut against the rod end.

8. Replace the other rod end if necessary.

9. Check the wheel alignment and correct if necessary.

The procedure for alignment is detailed at the begin-

ning of this section.

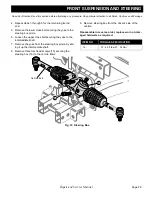

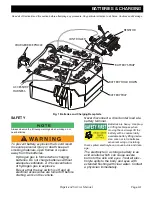

Steering Box

(Ref Fig. 12)

Tool List

Qty.

Torx Bit, T-45 IP ..........................................................1

Ratchet ........................................................................1

Torque Wrench, ft. lbs. .................................................1

Ball Joint Separator......................................................1

Ball Peen Hammer.......................................................1

Raise and support the vehicle as described in the Safety

section of this manual. Remove the front wheels as

described in the Wheels and Tires section of this manual

1. Loosen the nut securing the tie rod end to the spindle

arm.

2. Using a ball joint separator as a lever, apply pressure

to the ball joint and tap the spindle arm sharply with

the ball peen hammer to release tie rod from spindle

arm.

3. Remove the nut and remove the tie rod end from the

spindle arm.

ITEM

TORQUE SPECIFICATION

9

20 - 25 ft. lbs (27 - 34 Nm)

11, 13

22 - 27 ft. lbs (30 - 36 Nm)