Page

7

ML434_ES | v11

Expo Technologies UK

T: +44 (0) 20 8398 8011

Expo Technologies US

T: +1 (440) 247 5314

Expo Technologies China

T: +86 532 8906 9858

Section 5: Main Components

Air Supply Filter / Regulator

The unit is provided with a 40

μ

m liquid / dust filter element as a precaution. The user of the MiniPurge

®

system

must ensure that air supply is to the quality stated in Air Supply Quality paragraph found in the Installation of

the System section. The regulator is factory set to 5 barg (73 psig) and regulates the pressure of an air supply

between 5 and 16 barg (73 to 232 psig). A pressure gauge is fitted down stream of the filter; this should

indicate no less than 5 barg (73 psig). During the purge cycle a pressure drop will be indicated on the gauge.

Logic Air Supply Regulator

This device provides the system with a stable air supply pressure to the logic system and allows consistent

operation. The pressure level is factory set to 2.5 barg (36 psig) and can be verified by means of the integral

pressure gauge.

Minimum Pressure Sensor

This monitors the pressure inside the pressurized enclosure. When the pressure is below the minimum required

for safe operation, the pressure sensor causes the system to reset and the Alarm / Pressurized indicator turns

Red

.

The sensor is factory calibrated and set to operate in falling pressure at or above the minimum

specified pressure.

Purge Flow Sensor

The Purge Flow Sensor monitors flow through the Purge Outlet Valve. At correct purge flow rates, above the

minimum specified for purging, the sensor sends a signal that activates the purge timer. This sensor is factory

calibrated to operate on falling flow rate at or above the minimum specified purge flow rate.

Intermediate Sensor

This sensor monitors the pressure inside the pressurized enclosure. It senses when the pressure is drops and

provides early warning before the low pressure sensor trips the system.

Electronic Purge Timer

When both the enclosure pressure and the purge flow rate are correct, the Purge Flow Sensor activates the

timer and the electronic timer starts. The timing period is selected using switches mounted on the timer

module.

Note: Setting the timer to 00 minutes will cause infinite purging; the cycle will never complete.

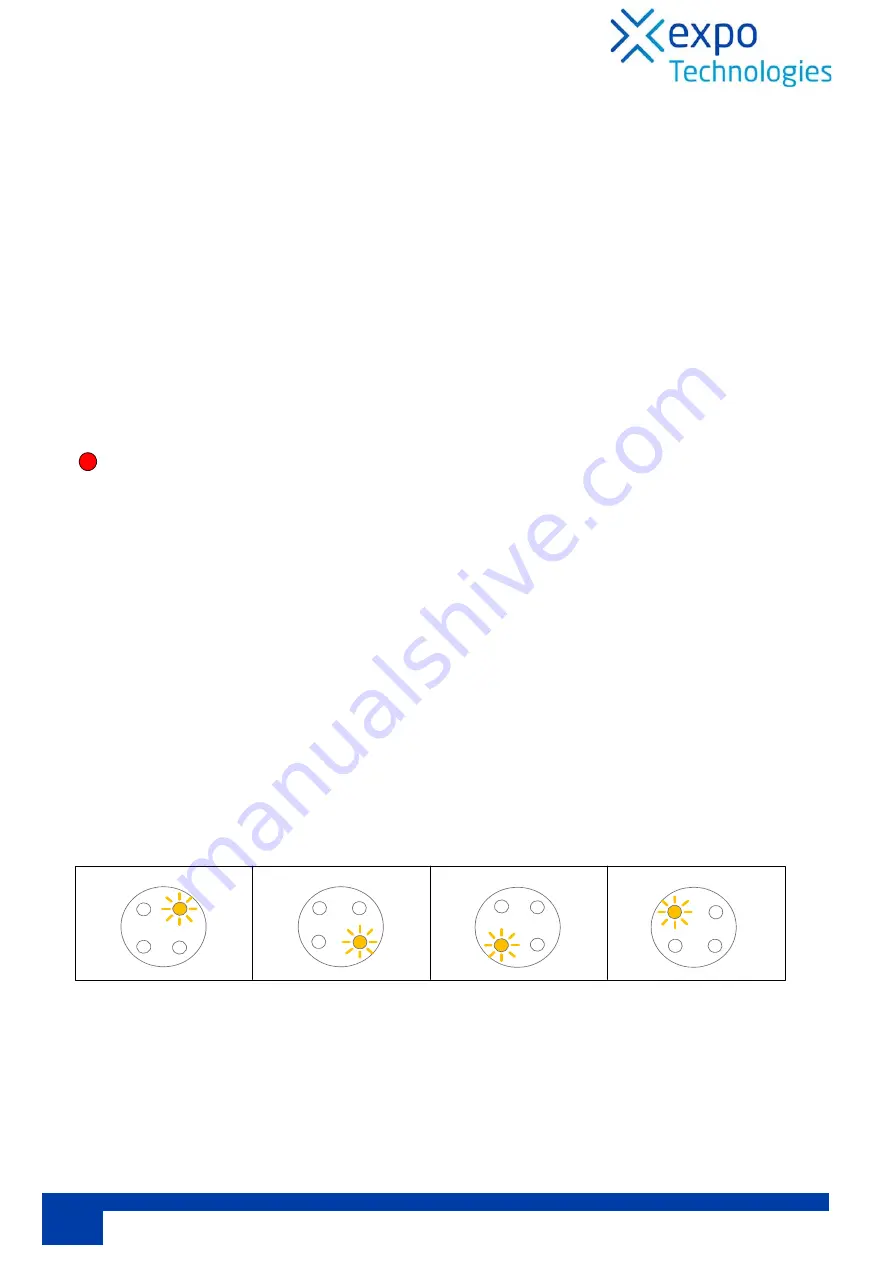

During timing, the percentage of the purge cycle is indicated by four LEDs which flashes sequentially while

the timer is running.

The Electronic Timer is powered by an EPPS (Electro-Pneumatic Power Supply.) Supply air must be available

for the EPPS to operate.

LED 1

LED 2

LED 3

LED 4

LED 1

LED 2

LED 3

LED 4

LED 1

LED 2

LED 3

LED 4

LED 1

LED 2

LED 3

LED 4

0 to 25%

of purge time

26 to 50%

of purge time

51 to 75%

of purge time

76 to 100%

of purge time