3

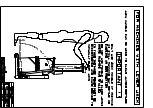

OVERLOAD RESET

BUTTON ----------

CHUTE OPEN

---- 10mm CAP SCREW

____ JACK GREASE

_________ BEARING GREASE

___ JACK STOP

BUCKET SEAL --------------

---------- TRAY PAD BUCKET

LOCATOR

OPERATING INSTRUCTIONS

1. Ensure that machine is plugged into a 240v 10 amp supply and that any

extension cord is not over 10m long.

2. Check level in bucket.

3. Turn machine on, ensuring that LED light is on. (LED light shows that

machine is running where background noise/music in bar makes it difficult

to hear that machine is running.

4. Ensure that all bottle caps are removed. Feed bottles into machine neck

first. Bottles can be fed immediately one after the other.

5. Once bucket or bin is full turn machine off. Wind jack handle clockwise to

lift housing/lid 50mm above bucket or use lever on newer models. Remove

bucket to empty. Replace bucket by locating bucket firmly against green

foam bucket locator pad. Wind jack handle anti-clockwise, ensuring that

lid flange does not catch on top of bucket. Bucket must seal against foam

seal on lid. Jack must be wound anti-clockwise until the sliding section of

the jack hits the 10mm Zinc Cap Screw located on the lower jack section.

This will ensure that the bucket is properly sealed. To ensure seal only use

the Expleco Bucket !!

Bottle Jam

1. On the rare occasion that a bottle jams in the feed in chute or stalls the

motor , carry out the following procedure.

2. Turn machine off and pull power supply plug from wall socket.

3. Using 8mm Allen wrench supplied, undo the chute retaining bolt and open

chute. Using protective gloves remove the jammed bottle or clogged glass

from the chute and/or main housing. Check that the main rotor and flail

assembly turns freely.

Summary of Contents for Oppressor GLC

Page 9: ...T 021324216 ...

Page 10: ......