- 29 -

l)

Re-install the seal guards over the wheel hub and insert wheel into caster

fork. Re-install caster bolt and tighten nut fully.

IMPORTANT

: To prevent seal and bearing damage, check the bearing

adjustment often. Spin the caster tire. The tire should not spin freely (more

than 1 or 2 revolutions) or have any side play. If the wheel spins freely,

adjust torque on spacer nut until there is a slight amount of drag. Re-apply

threadlocking adhesive.

5.1.16

Check spark plugs.

Service Interval:

160 hrs.

a)

Remove spark plugs, check condition and adjust plug gap or replace with

new plugs. See Engine Owner's Manual.

5.1.17

Remove engine shrouds and clean cooling fins.

Service Interval:

80 hrs.

a)

Stop engine, wait for all moving parts to stop, and remove key.

b)

Remove cooling shroud cleanout covers (Kohler) or cooling shrouds

(Kawasaki) from engine and clean cooling fins. Also clean dust, dirt, and

oil from external surfaces of engine which can cause improper cooling.

c)

Make sure cooling shroud cleanout covers or cooling shrouds are properly

reinstalled. Operating the engine without cooling shroud cleanout covers or

cooling shrouds will cause engine damage due to overheating.

5.1.18

Change fuel filter.

Service Interval:

As Required

a)

A fuel filter is installed in the fuel line between the fuel tank and the engine.

Replace when necessary.

For Kohler engines use

Kohler P/N 2405002

For Kawasaki engines use

Kawasaki P/N 49019-7001

5.1.19

Wheel hub - slotted nut torque specification.

When tightening the slotted nut on the wheel motor tapered shaft:

a)

Torque the slotted nut to 100 ft. lbs. (136 N-m).

b)

Further tighten the nut until the next set of slots line up with the cross hole

in the shaft.

c)

Replace cotter pin.

Note: Do not use anti-seize compound on the wheel hub.

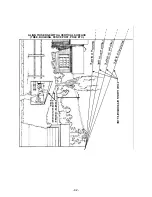

5.1.20

Thread locking adhesives such as “Loctite 242” or “Fel-Pro, Pro-Lock Nut-Type”

are used on the following fasteners:

a)

Pump drive sheave setscrews.

b)

Square head setscrews on Hydro pump control arms.

c)

Shoulder bolts in ends of speed control crank.

e)

OPC lever setscrews.

f)

Electric clutch retaining bolt.

g)

Pump drive idler pivot bolt.

h)

Fuel tank bulkhead fitting threads.

i)

Thumblatch screw threads on handles.

j)

Caster wheel spacer nuts. (Reference Section 5.1.15)

Adhesives such as “Loctite RC/609 or RC/680” or “Fel-Pro Pro-Lock Retaining I

or Retaining II” are used on the following:

a)

OPC lever hubs and cross-shaft