02027011 ZSME300000342

24

EXCELL PRECISION CO., LTD.

Chapter 4 Wireless Connection Instruction

Baud rate must be set as 9600 (bits/sec) and Communication protocol must be set as n81.

Step 1: Connect to your device

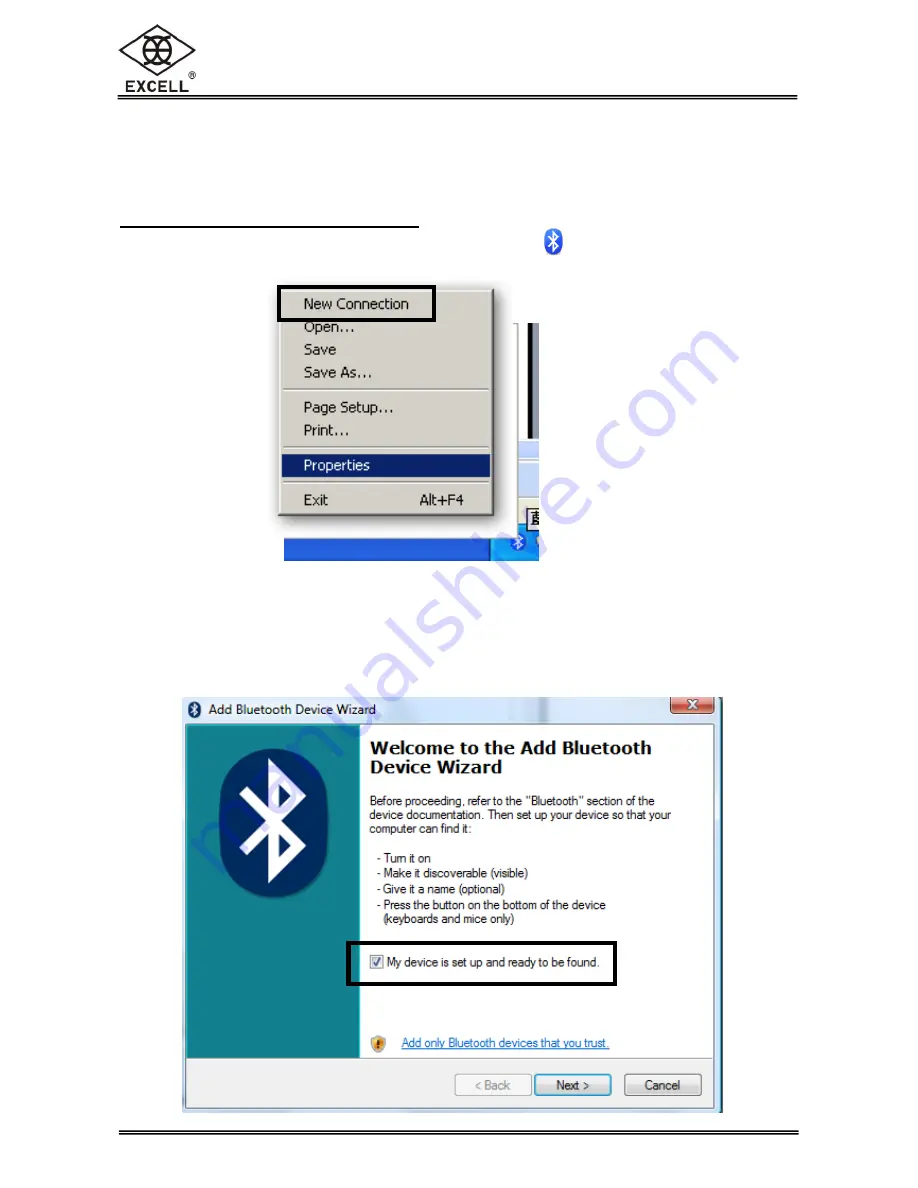

1. Enable Wireless on your computer. Right-click on the icon of the bottom-right corner

on taskbar, highlight “

New Connection

” and left click.

Due to the different bluetooth supplier software could be installed, the setting dialogs

shown below are just for reference.

2. Check “

My device is set up and ready to be found

” in the dialogue box.

Summary of Contents for GWS

Page 2: ......