Design and function

MIG/MAG welding

099-004833-EW501

22.04.2013

41

5.10.4.4 Accessory components for operating point setting

The operating point can also be set with various accessory components such as

• remote

controls

• special

torches

• PC

software

• robot and industrial bus interfaces (optional mechanised welding interface required – not possible for

all machines in this series!)

You will find an overview of accessory components in the "Accessories" chapter. See the operating

instructions for the machine in question for a more detailed description of the individual machines and

their functions.

5.10.5 MIG/MAG

welding data display

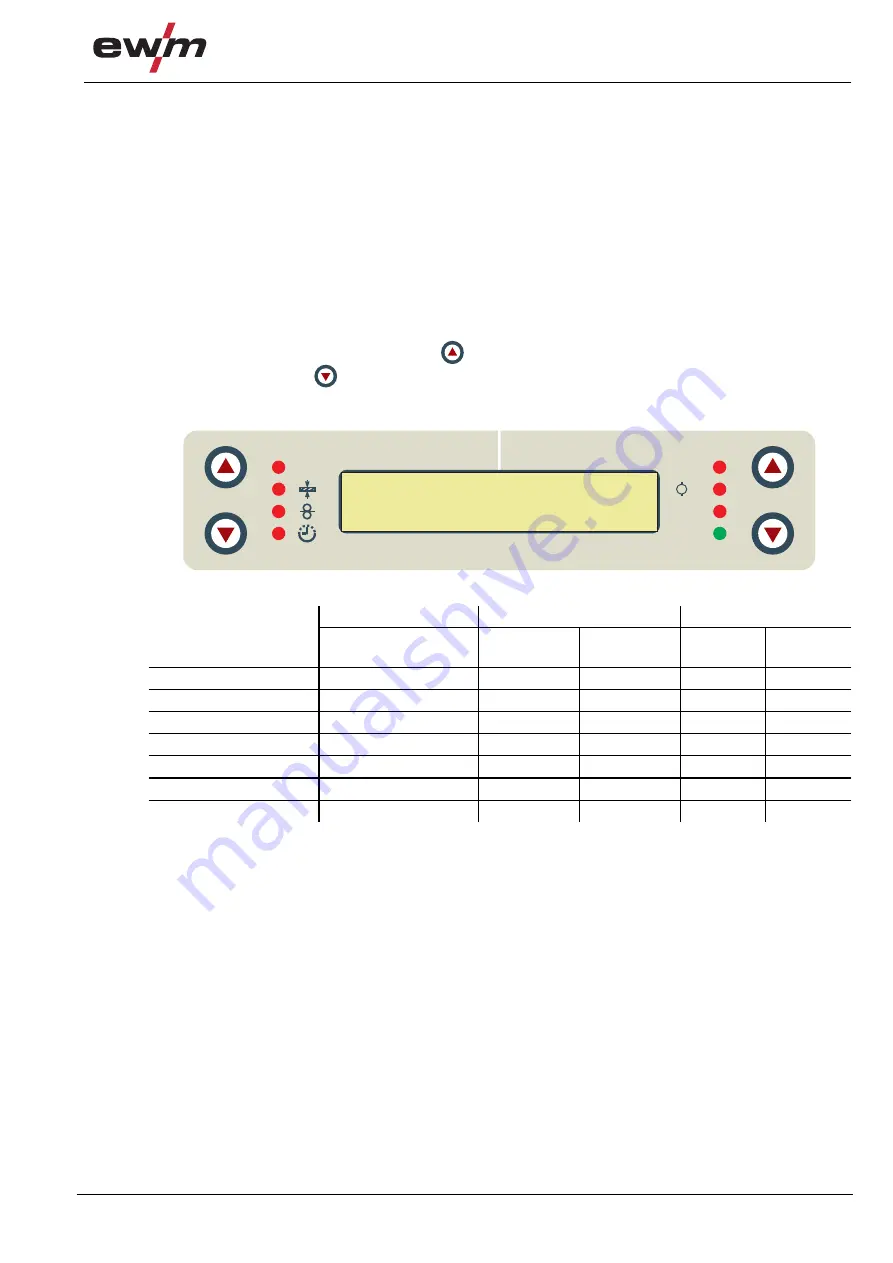

To the left and right of the LCD display on the control there are 2 “arrow keys” on each side for selecting

the welding parameter to be displayed. The

button is used to scroll through the parameters from the

bottom upwards and the

button is used to scroll downwards from the top.

As soon as changes have been made to the settings after welding (display on hold values), the display

switches back to the nominal values.

Figure 5-9

Parameter

Before welding

During welding

After welding

Nominal value

Actual value

Nominal

value

Hold

value

Nominal

value

Welding current

Material thickness

Wire speed

Welding voltage

Motor current

JOB no.

Operating time

A

V

Job Nr

Hold

A

M

Expert

500A 49.9V