9

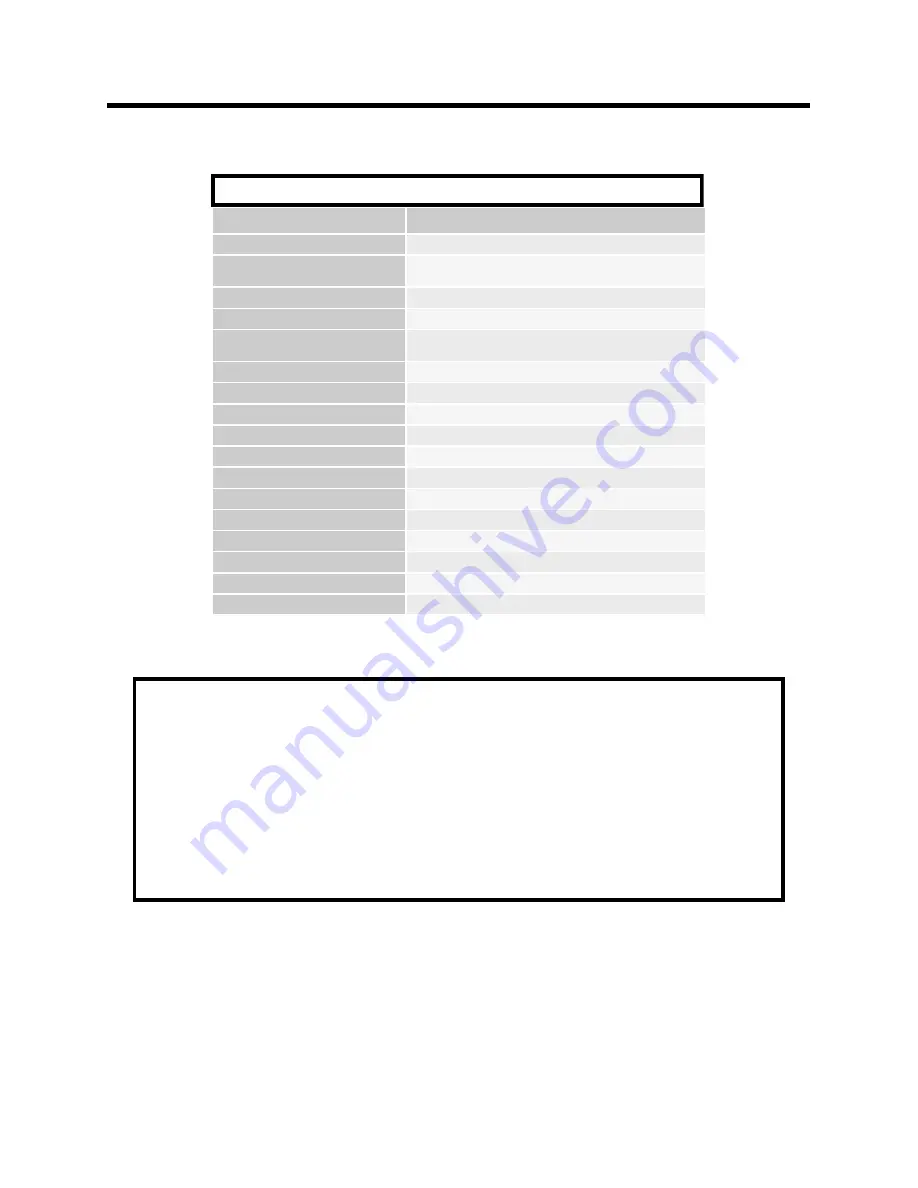

Specification:

PowerARC 300ST Stick/TIG welder

INVERTER TYPE

ANALOG CONTROLLED IGBT

INPUT VOLTAGE ±10%;PHASE/FREQUENCY

220V; 1 Phase and 3 Phase /50

-

60Hz

MAXIMUM INPUT AMPS (I₁max)

60A 220V 1 phase/ 45A 220V 3 phase

MAXIMUM INPUT RUNNING AMPS (I₁eff)

46.8A @ 220V 1 phase / 31A 220V 3 phase

DUTY CYCLE % @ AMPS

60% @ 300A/32V

100% @ 240A/ 29.2V

OUTPUT

20

-

300A, 20.8

-

32V

OPEN CIRCUIT VOLTAGE

70 V

TIG PACKAGE

OPTIONAL (Gas valve torch and regulator for scratch start DC use only)

CONSTANT CURRENT (CC) OUTPUT TYPE

DC (±)

CELLULOSE ROD CAPABLE 6010,6011

YES

INCLUDES

WELDER, WORK CLAMP WITH CABLE (10 FT),STICK TORCH WITH CABLE (10FT)

DINSE CONNECTOR TYPE

35/70mm² (DINSE 50 STYLE)

HOT START (SURGE CURRENT)

Adjustable

ARC FORCE CONTROL

Adjustable

MAXIMUM SUGGESTED ROD DIAMETER

1/4”

(6

-

7mm)

PROTECTION CLASS

IP21S

INSULATION GRADE

F

PERFORMANCE AND FEATURE COMPARISON

specifications

Section 1

IMPORTANT: The PowerARC 300 is DC output only and is not designed to weld aluminum or magnesium.

Need longer welding cables or an extension cord?

The welding cables are held into the DINSE style

connectors by set screws located under the connector cover and can be accessed by aggressively

twisting the rubber cover back and forth while pulling at the same time. A little effort may be required

the first time the connector cover is removed. If necessary, very lightly clamp the end of the connector

pin in a vise or with a pair of pliers while working the cover back until the cover pops off. The torch has

a small set screw that holds the cover in place. It acts as a wedge to hold the cover in place. It should be

loosened (not removed) and the cover slid back to access the set screw holding the cable in place.

When adding welding cable or using an extension cord make sure that the respective voltage/current

carrying capacity is sufficiently rated for carrying the maximum current of the welder over the dis-

tance of the cable.

Also, whether running long or short lengths, make sure the welder is strapped

down so any

“

whipping

”

movement of the cable will not overturn the welder or jerk it out of place.