19

INSTALL THE WIRE AND FEED THE GUN.

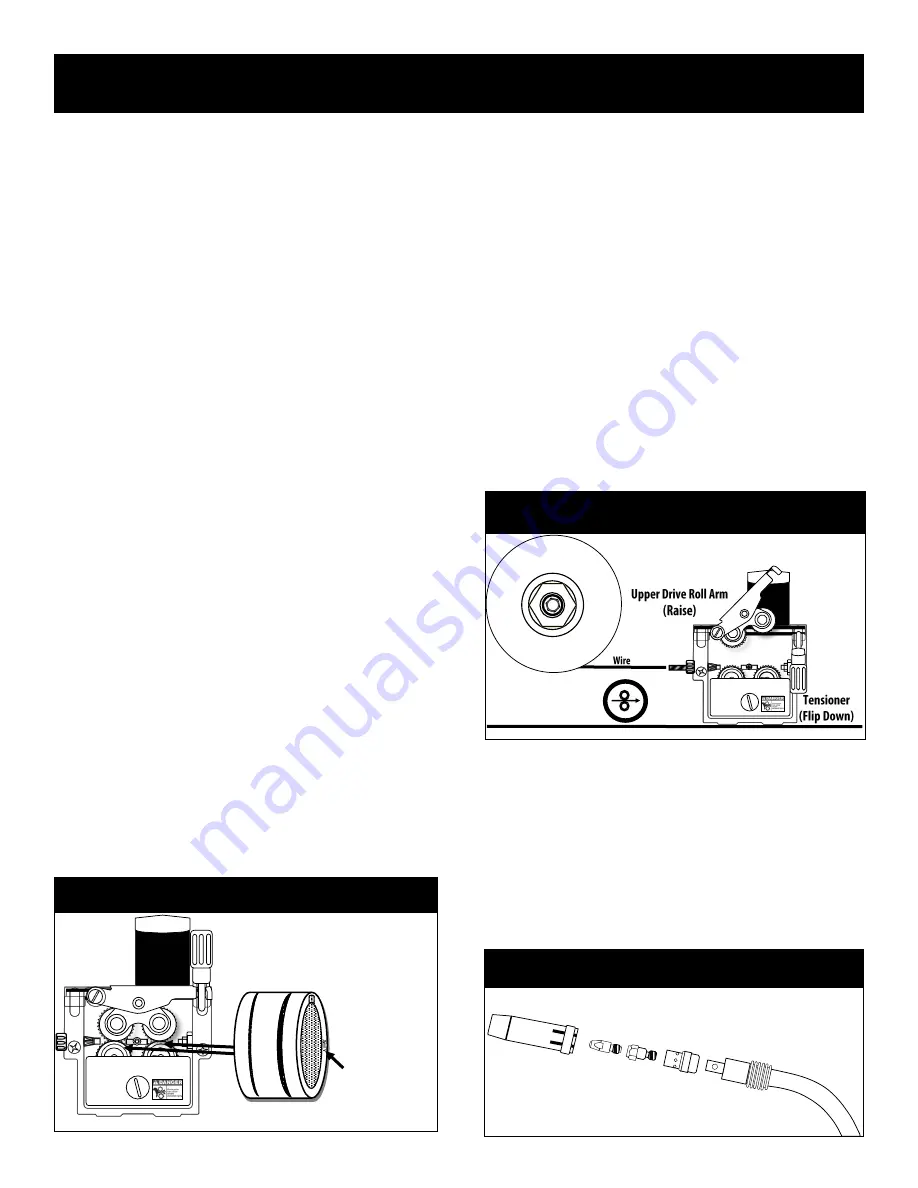

Once the wire spool has been installed, flip the tensioner lever down

and raise the top drive rolls to the upper position. See the illustration

below. Gently guide the wire from the spool over through the wire

feeder and into the front section of the gun at least 6 inches. Make

sure the wire lays neatly in the grooves of both drive rolls. Hold it

with your finger if necessary as you lower the upper drive roll arm

down and raise the tensioning lever into position with your other

hand. After the tensioner is raised back to the vertical position, con-

firm the wire is still in both grooves and is not riding up on the shoul-

ders of either drive roll. Next, turn the welder on and set to a desired

MIG or Flux

-

Cored mode. Remove the gas nozzle by pulling it with a

slight twist. Unscrew the contact tip as shown in the illustration be-

low. Use a wrench to hold the contact tip holder so it won

’

t unscrew

when the contact tip is removed. Hold the gun cable and gun straight

as possible. Press and hold the wire jog button. The wire should

slowly begin to feed through the gun cable and eventually through the

gun. As the wire exits the gun, allow 3 extra inches of wire to be fed

out past the diffusor. Release the wire job button. Re

-

install the con-

tact tip over the wire and screw it in clockwise until it is snug. Do not

overtighten. Install the gas nozzle.

Hint: The wire on the spool is usually bent and threaded through a

small hole in the side of the spool to lock it in place and prevent de

-

spooling of the wire. Keep one hand on the wire spool to prevent

despooling and cut the wire loose with a pair of wire cutters. Trim the

wire to make sure the end of the wire is straight and able to be

Setup Guide

Getting Started

CHECK AND CHANGE YOUR DRIVE ROLL.

The unit comes with a pair of

.035”

and

.045”

drive rolls installed.

Remember, if you change wire size or type, you will need to either flip

both of the lower drive rolls over for the opposing size or completely

change both of the drive rolls out with the ones of correct size and

type found in the consumable bag. When not in use, keep these

“

spares

”

put up where moisture and dust cannot get to them. They will

rust if not used and stored properly.

The top drive rolls are actually idler rolls used to hold tension and

keep the wire in the groove. These are not changeable. Only the bot-

tom drive rolls needs to be changed. Each of the bottom drive rolls

have two small grooves that are sized for

.030”

(.8mm)

and

.035”

(.9mm) solid wire. Additional sizes and types of drive rolls

are available as options. The standard installed drive roll is meant to

feed hard (solid) steel wire. The groove on this drive roll has a

“

V

”

shape designed for the solid wire. A Flux

-

Cored drive roll has a ser-

rated edge to the groove, which grips the softer, cored wire. Viewing a

flux

-

core drive roll from the top, you will see a

“

zipper

”

like pattern.

This should never be used to feed hard steel, stainless or aluminum

wire. This will result in damage to the wire, metal flaking and possible

plugging of the MIG gun liner. To determine the exact size of wire and

type you have, look at the side of the drive roll. The size of the drive

roll groove is stamped on the side of the drive roll closest to the corre-

sponding groove. The type of the drive roll will also be stamped with a

V if it is for solid, hard wire. If it is stamped with an

“

U

”,

this is a spe-

cial drive roll for feeding aluminum wire. Aluminum wire is best fed

with a spool gun.

The drive rolls are held in place by a screw. Use a flat head screw

driver to gently remove the screws to expose and change the drive roll.

The drive rolls are mounted on a bushing. To prevent the bushing

from being removed along with the drive roll, use the index finger of

one of your hands to hold the bushing while the other hand removes

the drive roll. When removing make sure that the square locating key

is not dismounted. If the key falls out of the keyway, replace it before

replacing the drive roll. When the drive roll is reinstalled, just lightly

snug the screws with the screw driver. Do not over tighten.

Drive Roll Size and Location Info

.6mm

=.023”/.025”

.8mm=

.030”

.9mm=

.035”

1.2mm=

.045”

1.6mm=

.062”

Size/Type Stamping.

(The size is stamped on

same side as the corre-

sponding groove.)

Installing the MIG Wire

How Do I Disassemble the MIG Gun?

M8

Contact Tip

Diffusor

Gas Nozzle

Contact Tip

Holder

Gun Neck

Drive Rolls X 2