7

Controls and inspections

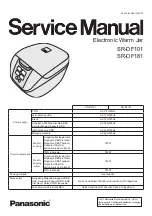

Before starting the appliance, check the oil level

through the sight glass located on the

motor/pump.

(Fig. 5.1). In order to access the pump, unscrew

the back panel of the appliance and remove it.

(Fig. 5.1

.) Pump oil level indicators

After checking the oil level and ensuring it is level

with the maximum oil level indicator, reinstall the

back panel and secure it with the screws you

removed. Connect the plug to the proper outlet.

If it is not the correct outlet, the outlet must be

replaced with the correct one by a qualified

electrician, as well as ensuring the fuse or

breaker is the correct current capacity for the

draw of the appliance.

Do not use adapters,

multiple outlets and/or extension cords.

Do not plug in multiple appliances on the same

outlet that may exceed current capacity of the

outlet.

This appliance must be grounded properly.

If the ground prong is broken, do not use

the appliance until it has been repaired or

serious injury or death may occur.

CHAPTER 6

USING THE VACUUM SEALER

Vacuum packaging

1. Plug in the grounded plug to the correct

outlet.

2. First turn on the main power switch on the

front of the appliance. Next press the

ON/OFF button on the control and the LCD

display should light up.

3. Set the vacuum time (or percentage)

required, the sealing time and the gas

injection time (if the appliance is equipped

with this option.).

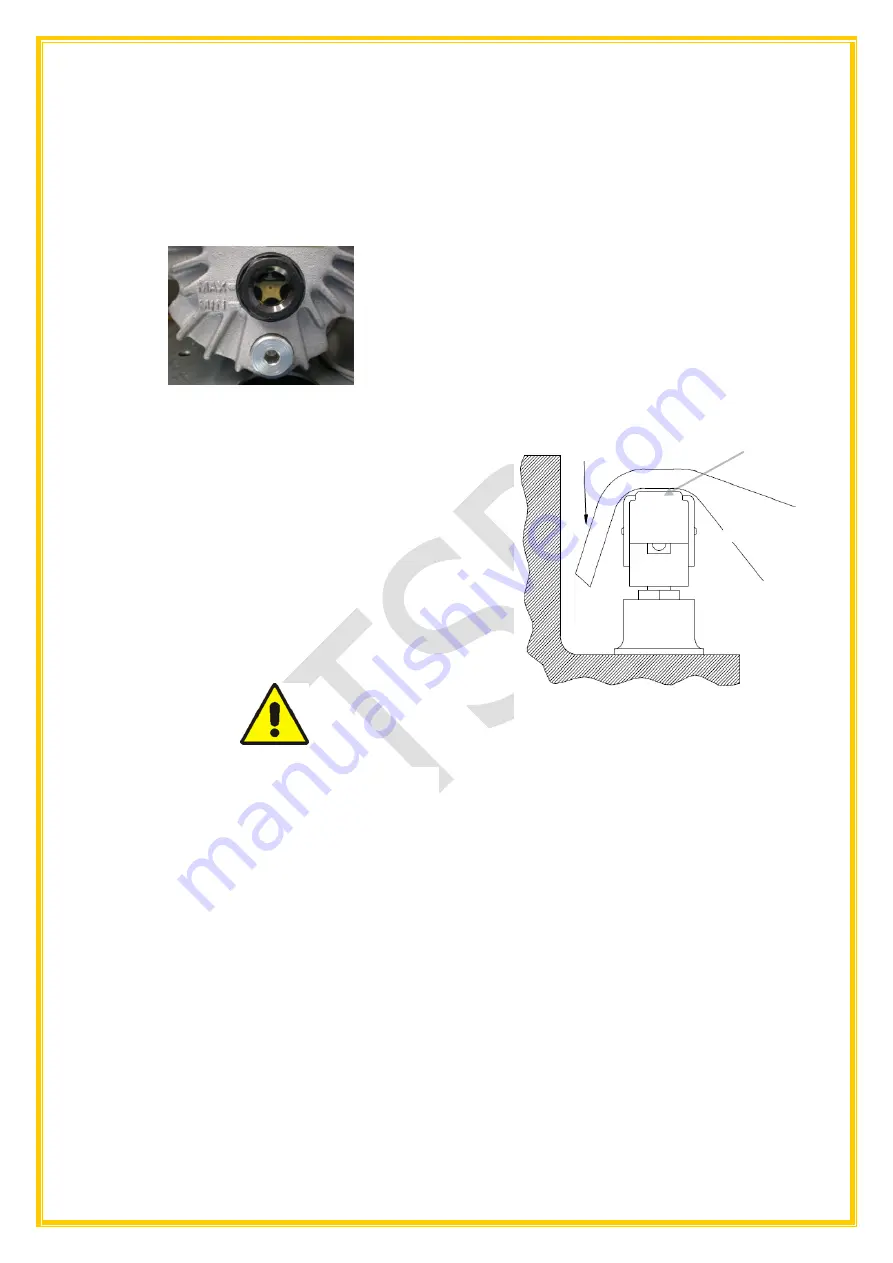

4. Position the bag (or bags) with product in

the chamber, the polyethylene shelves can

be used inside the vacuum chamber to level

the product with the sealing bar and position

the bag opening flat on the sealing bar.

The

polyethylene shelves can be removed

depending on necessity. (Fig. 6.1).

5. Lower the clear bell-lid and press firmly on it

until it remains closed, thus permitting the

sealing cycle to begin.

6. The different cycle phases are automatic and

after a pre-set amount of time the clear bell-

lid opens thus enabling the product to be

removed and subsequent cycles to begin.

(Fig. 6.1)

Correct bag placement in chamber

Vacuum-packaging with inert gas

injection OPTIONAL (ref. table 1)

1. Set the sealing cycle with inert gas injection

on the control panel by pre-selecting the

relative time.

2. Connect the hose coming from the gas

cylinder to the hose connection positioned

on the side/rear of the vacuum sealing

appliance by means of the relevant clamp,

then set the gas cylinder gauge at a

pressure value of 1 ATA.

3.

Position the bag containing the product

inside the vacuum chamber, fitting the gas

distribution nozzle inside the bag

opening

(Fig. 6.2); make sure that there are no folds

obstructing the gas flow.

Open end of bag

Sealing bag

Cross Section of Chamber

Sealing

Bar

Summary of Contents for PrepRite PVS27-6-1

Page 17: ...17 CHAPTER 11...

Page 18: ...18 EXPLODED VIEWS AND PART...

Page 19: ...19 LISTS...

Page 20: ...20...

Page 21: ...21...

Page 22: ...22...

Page 23: ...23...

Page 24: ...24 CHAPTER 12 WIRING DIAGRAMS PVS27 PVS32 PVS32G PVS42 PVS42BG PVS5225 PVS52G...

Page 25: ...25...

Page 26: ...26...