7

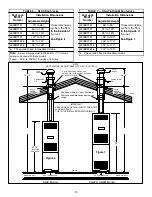

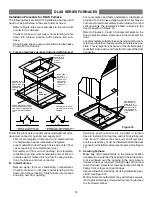

Figure 3

FURNACE

INSTALLED

IN CLOSET

FULLY

LOUVERED

DOOR

TWO RETURN

AIR GRILLES

THREE RETURN

AIR GRILLES

Furnace front door clearances of 0” to less than 6” from closet door

FURNACE

RETURN

AIR GRILLES

250 SQ.

IN.

MIN. FREE

AREA

250 SQ.

IN.

MIN. FREE

AREA

UPPER

HALF

50 SQ. IN.

MIN. FREE AREA

50 SQ. IN.

MIN. FREE AREA

NOTE: LOCATE

GRILLES IN LINE

WITH ALL FURNACE

RETURN AIR

GRILLES **

** WHEN THE FURNACE FRONT DOOR CLEARANCE IS GREATER THAN 1” BUT LESS THAN 6” TO THE CLOSET DOOR,

THE RETURN AIR GRILLES IN THE CLOSET DOOR NEED NOT LINE UP DIRECTLY OPPOSITE THE RETURN AIR

GRILLES IN THE FURNACE DOOR.

NOTE: LOCATE

GRILLES IN LINE

WITH ALL FURNACE

RETURN AIR

GRILLES **

250 SQ.

IN.

MIN. FREE

AREA

APPLICATION 1

APPLICATION 2

APPLICATION 3

UPPER

HALF

UPPER

HALF

RETURN AIR REQUIREMENTS

Closet Return Air Requirements

A. With six inch or greater clearance from front of 7900 se-

ries furnace to closet door.

IMPORTANT

Closet door must have a minimum of 250 sq. in. free

opening for return air. Opening can be located in the

front door or above furnace casing. If opening for return

air is located in the floor or sidewalls anywhere below

furnace casing height, 6 inches minimum clearance

must be provided on side where return is located, and

the 6 inches minimum clearance must be maintained

from the front of furnace. See Figure 2.

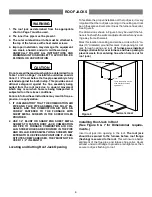

B. With zero to less than six inches clearance from front

of 7900 series furnace to closet door.

IMPORTANT

a. With fully louvered closet door - the upper one half

of the door must have a minimum of 250 sq. in. free

area. See Figure 3, Application 1.

b. With two return air grilles in closet door - the upper

grille must have a minimum of 250 sq. in. of free

area, and must be placed in the upper half of the

door so it is directly opposite the two return air

grilles in the upper furnace door. See Figure 3,

Application 2.

c. With three return air grilles in the closet door - the

total free area of the two upper grilles must be a

minimum of 250 sq. in. The grilles must be placed

in the upper half of the door so each grille is directly

opposite the corresponding return air grille in the

furnace door. See Figure 3, Application 3.

d. When the furnace front door clearance is greater

than 1” but less than 6” to the closet door, the re-

turn air grilles in the closet door need not line up

“directly” opposite the return air grilles in the fur-

nace door.

Additional requirements for floor and ceiling return system

for closet installed sealed combustion heating appliance

are given in the next paragraph.

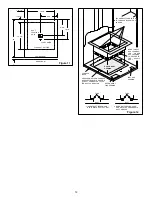

Floor or Ceiling Return Air System

Floor or ceiling return air system for closet installed direct

vent forced air heating appliance.

Listed in the next paragraph are the conditions to be met by

Mobile Home Manufacturers to have U.L. acceptance of in-

floor or ceiling return air systems of closet installed direct

vent forced air heating appliances for Mobile Homes to be

sold in the United States.

A. The return-air opening into the closet, regardless of lo-

cation, is to be sized not less than specified on the

appliance’s rating plate.

B. If the return-air opening is located in the floor of the

closet (versus the vertical front or side wall), the open-

ing is to be provided with means to prevent its inadver-

tent closure by a flat object placed over the opening.