21

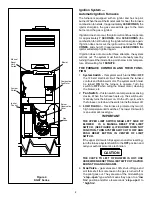

GAS PIPING

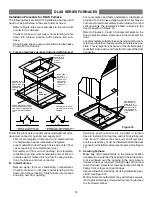

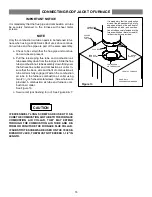

INSTALLATION AND CHECKING OF GAS LINE

Gas Supply piping must be sized in accordance with the

recommendations contained in “American National Stan-

dard Institute Installation of Gas Piping” ANSI 223.1 unless

local codes or regulations state otherwise.

Materials used and pipe sizing for U.S. mobile homes must

comply with requirements contained in Mobile Homes

A119.1, Recreational Vehicles A119.2 and H.U.D. Title 24,

Section 280.705 and any local or state codes.

NOTE

The gas line inlet on the gas valve is 1/2-14 N.P.T. The gas

line may be installed through the furnace floor or furnace

side to the gas valve.

CAUTION

To install gas line and to connect it to the gas valve, care

must be taken to hold gas valve firmly to prevent mis-

alignment of the burner orifice, or to damage gas valve

which could result in improper heating, explosion, fire

or asphyxiation.

DO NOT USE EXCESSIVE PIPE SEALANT ON PIPE

JOINTS. Pipe sealant, metal chips or other foreign ma-

terial that could be deposited in the inlet of the gas

valve, when gas pipe is installed or carried through the

gas piping into the gas valve inlet after installation, may

cause the gas valve to malfunction and could result in

possible improper heating, explosion, fire or asphyxi-

ation. Also, pipe sealant must be resistant to Propane

gas.

Where regulations require, a main shut-off valve shall

be installed externally of furnace casing. After piping

has been installed, turn gas on and check all connec-

tions with a leak detector or soap solution.

NEVER USE OPEN FLAME. FIRE OR EXPLOSION

COULD OCCUR.

Do not test the fuel system at more than 14” W.C. after

furnace has been connected to fuel line. Such testing

could void the warranty. Any test run above 14” W.C.

may damage furnace control valve which could cause

an explosion, fire or asphyxiation.

A dirt leg may be required by some local codes to trap mois-

ture and contaminations.

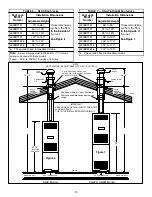

For NAT. gas operation, the furnace is designed for 7” W.C.

inlet gas pressure. Pressure to main burner is then reduced

to 3-1/2” W.C.

For Propane gas operation, pressure measured at the gas

valve must be 11” W.C.

IMPORTANT

When converting valve from or to Propane gas, it will be

necessary to change main burner orifice to prevent an un-

derfired or overfired condition. See furnace nameplate for

complete instructions.

FINAL PROCEDURE

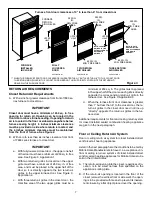

Install Furnace Doors

Install the bottom door first by holding the door flush

against the casing and sliding the door down until the

door top and bottom flanges rest in the casing chan-

nels. Then install the upper door in the same manner.

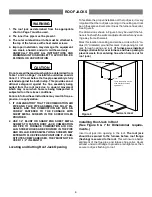

Alcove and Closet Installations may now be fin-

ished and trimmed as necessary

Leave enough gap above upper furnace door to allow it

to be lifted and removed.

NOTE

See nameplate for conversion and lighting instructions. Ob-

tain a temperature rise within the ranges specified on the

name plate.

CAUTION

When installing an air conditioner which does not use the

furnace blower for air distribution and operates completely

independent of the furnace, THE THERMOSTAT SYSTEM

MUST HAVE AN INTERLOCK TO PREVENT THE FURNACE

AND AIR CONDITIONER FROM OPERATING AT THE SAME

TIME. This interlock system usually contains a heat-cool

switch which must be turned to either HEAT or COOL to acti-

vate either heating or cooling operation. This prevents po-

tentially hazardous high temperatures in any room if both

systems operate at the same time.