24

Controller User Manual

The probe type connected to universal input U1.

The process value of the lower reading used to establish a

scale. This is not required for all sensor types.

The process value of the upper reading used to establish a

scale. This is not required for all sensor types.

The amount of time that is allowed to elapse after the

connection to the sensor is lost before an alarm is generated.

NTC if Dry Cooler

4-20 mA if Condenser

Various

Various

60 seconds

Parameter

Description

Default

Table 8

The parameters associated with the process sensor.

Probe Type

Minimum Value

Maximum Value

Alarm Delay

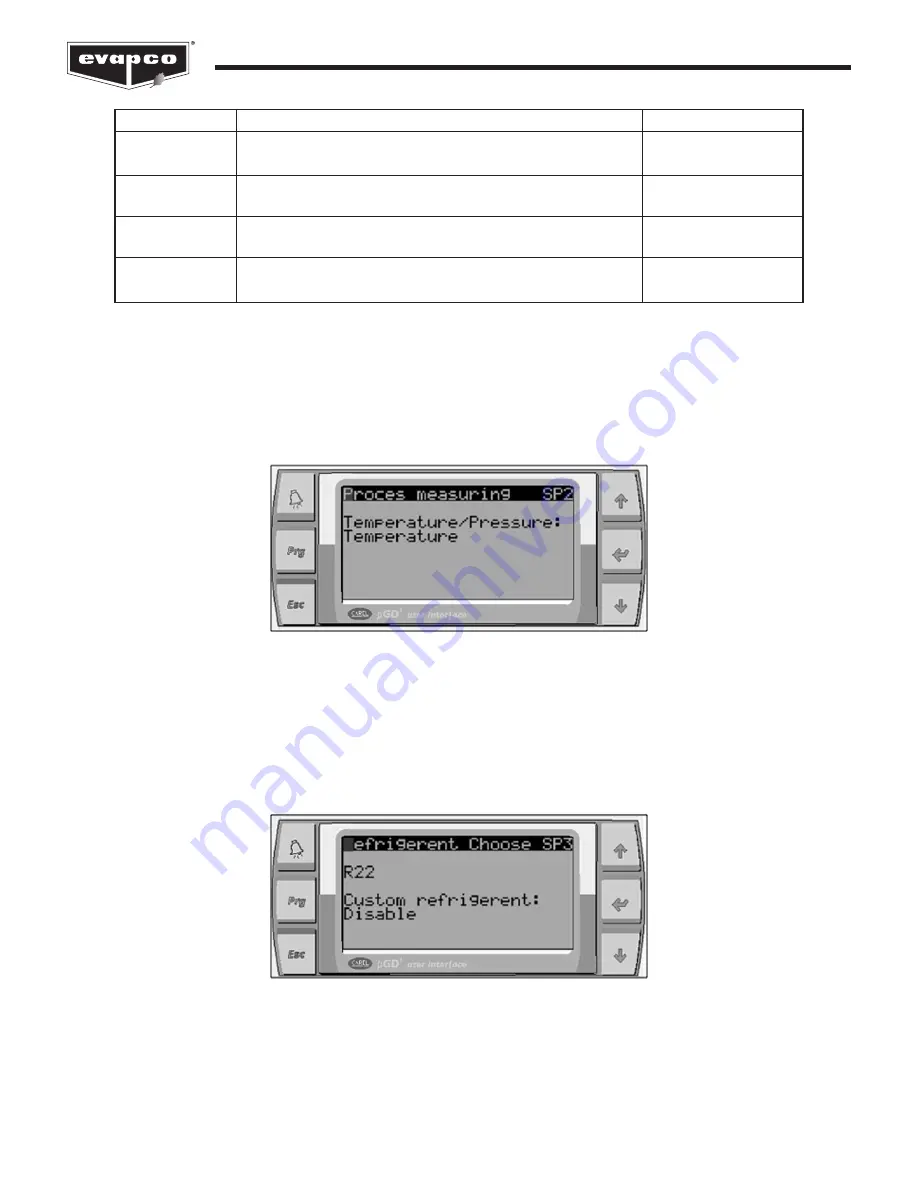

Figure 42

The process measuring is set as temperature in this example.

The screen shown in Figure 42 allows the user to determine if the process sensor is measuring a temperature value or a

pressure value. Note that this setting will be set at the factory and should not require modification. For fluid coolers, the default

setting will be

Temperature

and for condensers the default setting will be

Pressure

.

Figure 43

The refrigerant is chosen as R22 in this example.

If the eco-Air unit is a condenser, and the process measuring is set as

Pressure

in Figure 42, the screen shown in Figure 43 will

be shown. When the EVAPCO Controller ships from the factory, the proper refrigerant for the application is already

programmed. Refer to Table 9 for a list of the available refrigerants. If the desired refrigerant is not listed in Table 9, a custom

refrigerant may be selected by selecting

Enable

.