AT ATLAS Induced Draft Counterflow Cooling Towers

16

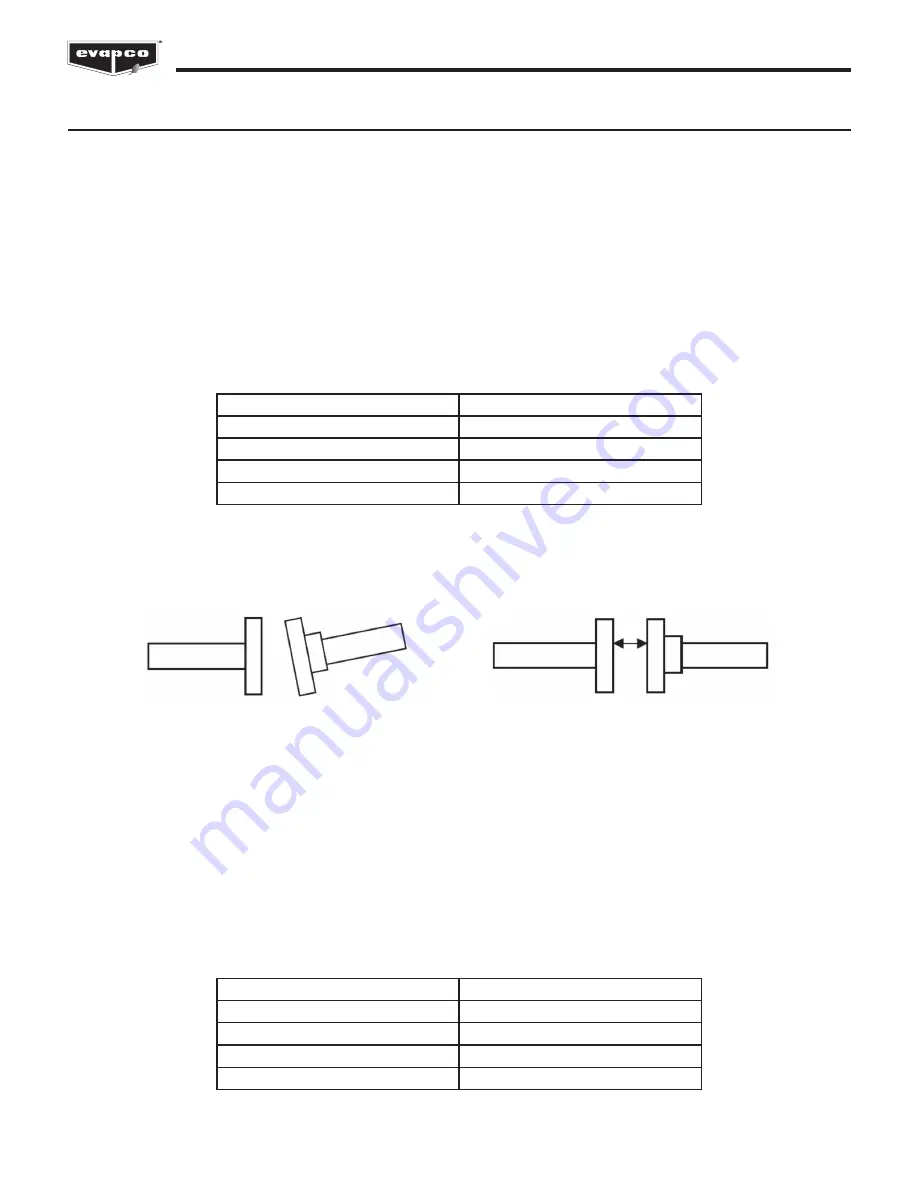

5. Check angular and axial misalignment between the drive shaft and both the motor and gear drive couplings.

6. Check angular misalignment with a dial indicator on gear drive side.

7. Attach the dial indicator support to the drive shaft and position the indicator tip to read off the opposite side flange.

8. With the dial indicator set to zero, rotate the shaft 360° and record the indicator readings at 90° increments.

9. The range between minimum and maximum values should be less than 0.010” (0.25mm). If alignment is out of tolerance, add

shims (not exceeding 1/4”).

10. When the angular alignment is within the acceptable ranges as mentioned in step 9, securely tighten all gear drive hardware.

11. Repeat steps 6 through 10 on the motor side of the drive shaft.

12. Check axial misalignment with a tape measure or dial caliper. Refer to Table 5 for axial alignment gap limits.

Angular Misalignment

Axial Misalignment

Table 4 - Torque Requirements for Floating Shaft Assemblies

Shaft Model

Torque Requirement

LRR 350

400 in-lbs (33 ft-lb 45 Nm)

LRR 375

400 in-lbs (33 ft-lb 45 Nm)

LRR 450

145 in-lbs (12 ft-lb 16 Nm)

LRA 485

240 in-lbs (20 ft-lb 27 Nm)

Floating Shaft Installation & Alignment

The fan motor and gear reducer will ship mounted to the mechanical equipment support. The system will be prealigned in the

factory, however alignment should be verified prior to rigging the mechanical equipment support to the fan section.

The steps for alignment of the floating shaft are:

1. Mount the drive shaft with the flexible element assembly on the gear drive input shaft using the supplied 3/8” (10mm)

hardware. All bolts, lock washers and nuts are supplied with the drive shaft kit.

2. Insert steel bushings into the composite flexible elements on the motor side.

3. Mount the drive shaft with the flexible element assembly on the motor output shaft using the supplied 3/8” (10mm) hardware.

All bolts, lock washers and nuts are supplied with the drive shaft kit.

4. Torque requirements for the bolts are listed in Table 4 (these values are dependent upon the shaft model). Use a torque

wrench to properly torque all drive shaft bolts.

Table 5 - Axial Alignment Gap Limits

Shaft Model

Axial Alignment Gap Limits

LRR 350

0.42-0.44 in. (10.7mm-11.2mm)

LRR 375

0.53-0.55 in. (13.5mm-14.0mm)

LRR 450

0.42-0.44 in. (10.7mm-11.2mm)

LRA 485

0.58-0.62 in. (14.9mm-15.9mm)