Document ID:06080001

Rev: L

Technical Support: 800-626-6912

Page 9 of 24

I

MPORTANT

I

NSTALLATION AND

U

TILITY

I

NFORMATION

Electrical Service:

110V:

A 110V, 60 Hz, 15 Amp GFCI protected grounded circuit must be used to supply power

to the pedicure spa. (220V if ordered in 220V configuration)

220V:

A 220-240VAC, 50Hz, 7.5 Amp GFCI protected grounded circuit must be used to supply

power to the pedicure spa per local code.

Water Supply:

All plumbing connections must conform to local codes.

Normal water pressure of 30 to 80 PSI is required to correctly fill the basin to the proper level.

The hot water supply temperature must not exceed 150

°

F (65

°

C). Adjust your hot water heater

accordingly.

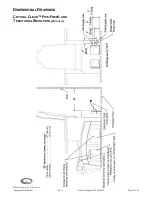

For hot and cold water supply fittings and power drain fittings location, see figure 1 below.

Carefully connect the incoming water supply lines to the appropriate fittings located on the back of the

pedicure spa. Shut-off valves are recommended.

Backflow Protection Devices for Faucets with Side Spray: Check valves comply with

ANSI/ASME A112.18.3M, A112.18.1M, and CSA B125

ANSI/ASME A112.18.3M (Performance Requirements for Backflow Protection Devices and Systems in

Plumbing Fixture Fittings) is applicable to plumbing fixture fittings with outlets not protected by an air

gap. Included in the possible range of applications are fittings with hose connected outlets, fittings with

pullout spout, hand held showers, shampoo fittings and deck-mounted fittings. ASME A112.18.3M is

now referenced in ASME A112.18.1M (Plumbing Fixture Fittings) and CSA B125. Check valves are

listed to both standards with the Canadian Standards Association, IAPMO and UL.

ANSI

- American National Standards Institute

ASME

- American Society of Mechanical Engineers

CSA

- Canadian Standards Association

IAPMO

- International Association of Plumbing and Mechanical Officials

UL

- Underwriters Laboratory

The pedicure spa drain must meet local plumbing codes.

Check valve for drain (not provided) must

be installed by a licensed plumber.

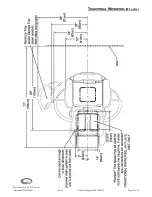

Pedicure spa must be securely fastened to the floor as shown in figure 2 below. Fasten the pedicure

spa to the floor with at least two fasteners, one in the middle plastic support and one in the rear plastic

support.

Back of Pedicure Spa

Install Fasteners Here

Figure 1

Figure 2