www.eurolube.com

EUROLUBE EQUIPMENT AB

–

PART NO 26700, 257-51, 257-52 / ART.NR. 26700, 257-51, 257-52

POWER RAM PUMP HOIST

2

www.eurolube.com

2

842 806 R. 09/12

Samoa Industrial, S.A. · Box 103 Alto Pumarín · 33211 Gijón - Asturias Spain · Tel.: +34 985 381 488 · Fax.: + 34 985 384 163

2012_09_26-10:30

Read all instruction manuals, tags, and labels before operating

the equipment.

This equipment is for professional use only.

Do not alter or modify this equipment. Use genuine components

provided from SAMOA Industrial, S.A.

The non compatible fluids may cause damage in the pump and

serious personal injury.

The pump generates high or very high pressures. Do not exceed

the maximum air inlet pressure of 10 bar.

Do not exceed the drum’s pressure limits. Be sure of the drum’s

pressure limitations and regulate the pressure within the safety

limits when supplying air to the inductor plate. Do not try to use

the unit until you have taken all possible precautions to

guarantee that the unit has been installed correctly and that the

base has been firmly secured to the concrete floor.

WARNING

!

Warning and cautions

This symbol aware of serious bodily injury or death if you

ignore the warning described.

!

WARNING

!

CAUTION

This symbol aware of personal injury or property damage if

you ignore the caution described.

Read before use

Avoid electrical discharges. Ensure there are no electrical cables,

devices or accessories above the hoist. Examine the work area

and take the measures necessary to ensure that enough space is

maintained for the installation of the hoist and for the pump to

be lifted as much as possible and that they work correctly.

Maintain a minimum safety distance when raising and lowering

the inductor. Do not get too close; operate it from a safe place,

so you cannot get trapped between the unit and its mobile

elements. Take care when inserting the inductor plate into the

drum.

When not in use, be sure to shut off the air supply to avoid

accidents.

Check that all the operators that work with this unit have been

trained in safe working practices, that they understand their

limitations and use safety equipment when required.

If the unit is not installed correctly this can result in

serious injury or material damage. Read the warnings.

(See warnings and precautions)

.

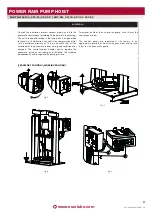

This unit comes completely assembled, apart from the following

details for proper installation and commissioning.

The unit is supplied with the control cabinet in the transport

position. To place the control panel in the working position,

simply disconnect pipes A and B from the control panel (see Fig.

5) and remove the pin from the hole locking the control panel

(see upper arrows) and lower the control panel into its new

working position (see arrow for rotational direction). Once the

control panel is in place, insert the pin making sure the holes of

the new position coincide. This will lock it in the working

position. Then connect the pipes in the lower part of the control

panel according to the diagram (see Fig. 5).

Installation

To facilitate its handling, the unit is supplied with a pallet system

integrated in the design. This system is composed of two

galvanised sheet metal profiles bolted to the base plate. Once

you have selected where you will secure the unit, it is necessary

to remove these profiles; to do this, loosen and remove the

screws that secure them and then remove the profiles in the

direction of the arrows. Take care when doing so to avoid

possible accidents.

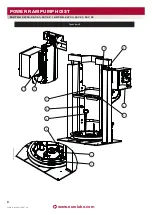

Once the definitive location of the unit has been defined, pay

special attention to the work area that will be above the

inductor; this work area shall be free of objects and any electrical

devices. Once you have finished the above step, secure the unit

definitively. To do this, firmly secure the base to the concrete

floor using anchor bolts (not included in the supply). The base

plate itself can be used as a pattern to establish the correct fixing

locations.

!

WARNING