SD20-G Series

41

3.2 Servo motor installation

3.2.1 Installation location

1. Install the servo motor in an environment free from corrosive or inflammable gases or combustibles, such as

hydrogen sulfide, chlorine, anmonia, sulphur gas, chloridize gas, acid, soda and salt.

2. Select and use the servo motor with oil seal in a place with grinding fluid, oil spray, iron powder or cuttings.

3. Install the servo motor away from heat sources such as heating stove.

4. Never use the servo motor in an enclosed environment. Working in the enclosed environment will lead to high

temperature of the servo motor, which will shorten its service lift.

3.2.2 Installation conditions

Environment

conditions

Equipment location

Prevent tangy caustic gases and flammable gases

Altitude

1000m or below

Atmospheric pressure

86kPa~106kPa

Operating temperature

-15°C~40°C

(

no freezing

)

Storage temperature

-20~80°C

Humidity

Below 90% (no water-bead coagulation)

Vibration Strength

Below 0.5G

(

4.9m/s2

)

,10~60Hz (Discontinuous)

IP rating

IP64

Summary of Contents for SD20-G Series

Page 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Page 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Page 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Page 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Page 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

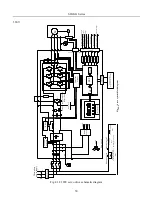

Page 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...