23

2124662-03-05/18 (translation of the original operating instructions)

Operating Instructions

Transponder-Coded Safety Switch CTP-L.-AS1

EN

19

39

20,5

max. 50

38

25

25

21,5

38

25

39

32,4

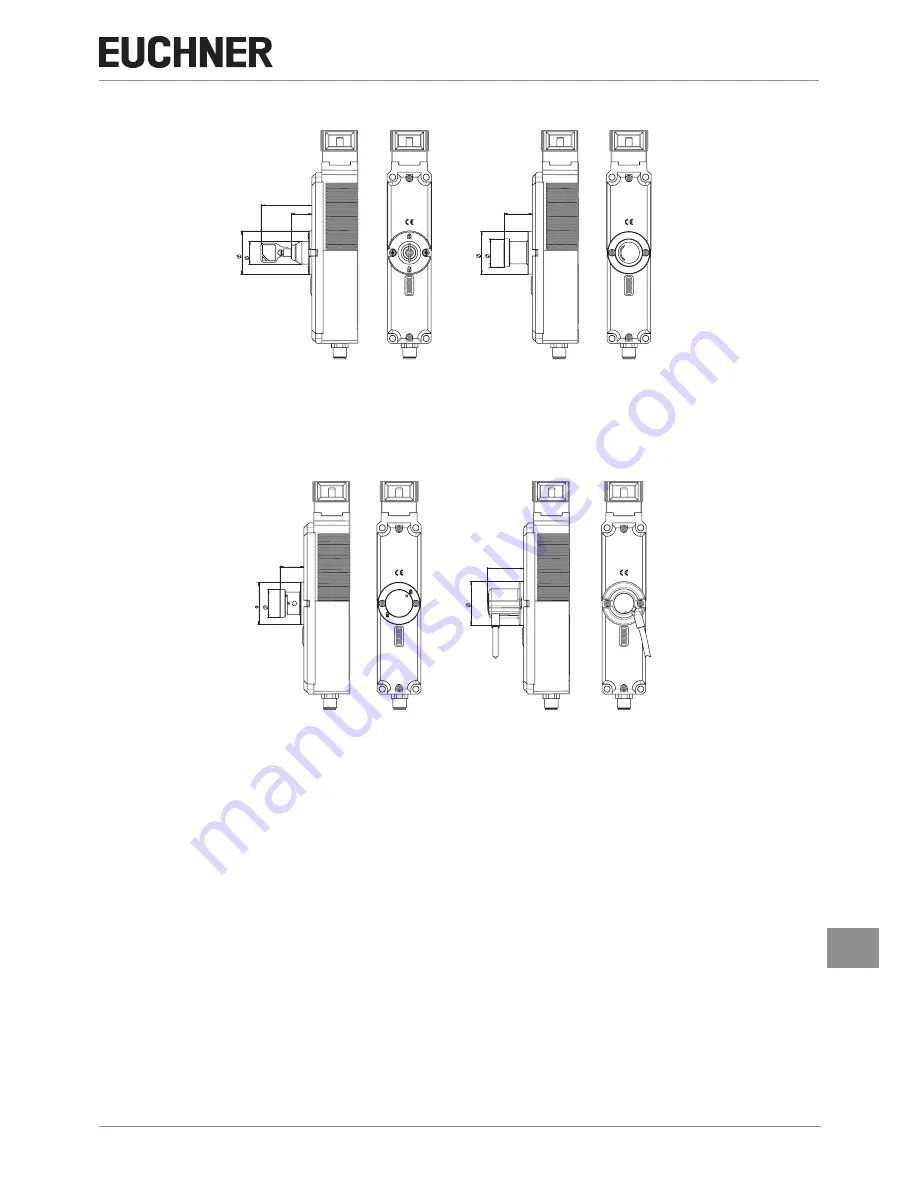

With auxiliary key release

With wire front release

With auxiliary release

With emergency unlocking