16

removed from the drying column and spread evenly, one

granule deep on a tray. The desiccant should then be heated

for approximately one (1) hour at about 400ºF (200º C). It

should be allowed to cool in an airtight container before

refilling the acrylic drying column. The felt filters should also

be pre-dried at 200º F (100º C) for about 30 minutes before

assembly.

3.2.2 System

Function

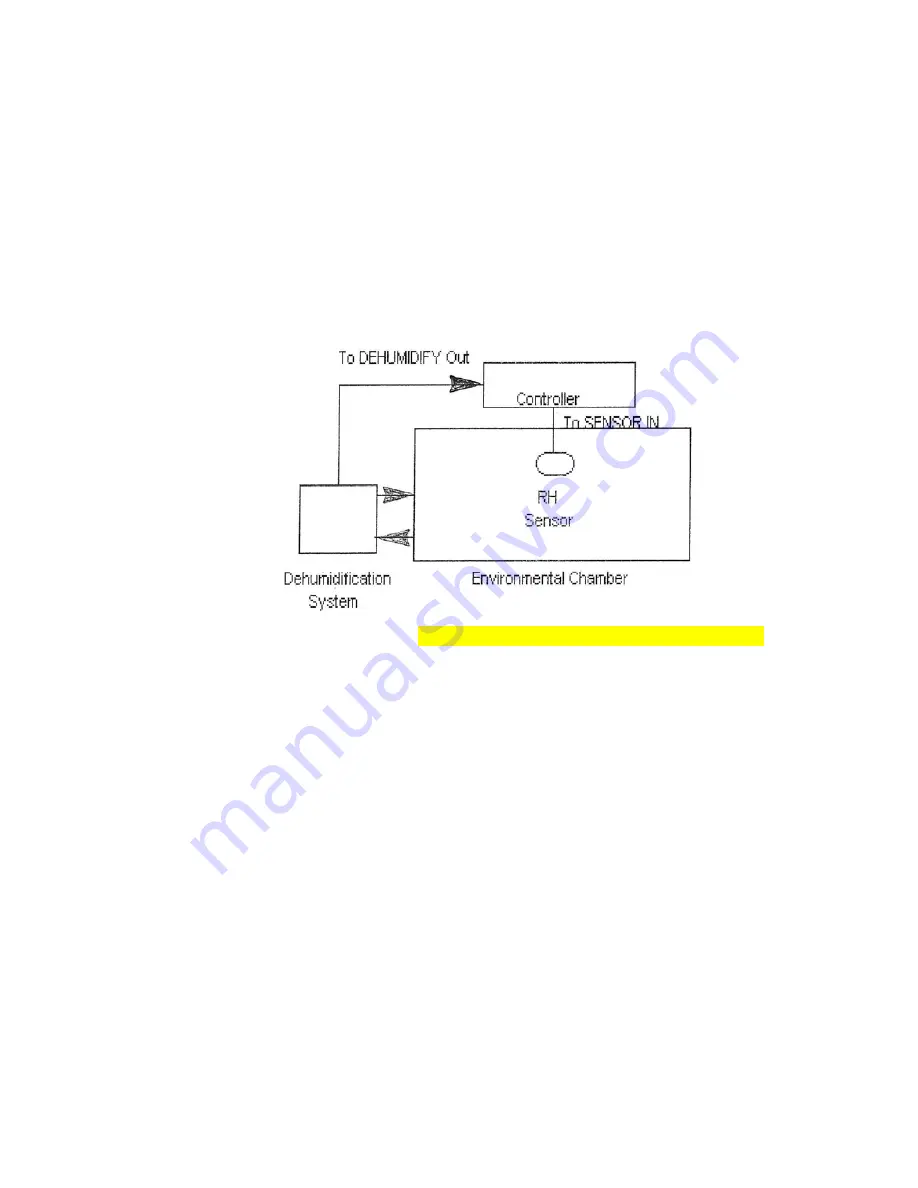

Figure 3.2-4 is a block diagram illustrating the Dehumidifier

Controller and Dehumidification System connected to the Model

5506 Chamber.

Figure 3.2-4 Controlled humidity chamber block diagram

The Humidity Sensor measures the relative humidity inside the

chamber. The Sensor output signal is then compared to the set

point. When the humidity measured in the chamber exceeds the set

point the Controller turns on the pump circulating the test chamber

air through the desiccator or injecting dry gas through a solenoid

valve. For the desiccator system the desiccant absorbs moisture,

thereby lowering the humidity level inside the chamber. For the dry

gas system the dry gas replaces the wet air that is ejected into the

atmosphere or through a vent. When the humidity level drops below

the set point, the Controller turns off the pump. The pump will then

cycle on and off automatically as required by the Controller to

maintain the desired humidity level.

Power to operate the Dehumidification System is controlled by a 3

amp solid-state relay. When the measured humidity deviates from

the R.H. set point the Controller turns on the relay which then

supplies the necessary 115/230 VAC power to the system.